Your Full Service Supplier to Nickel Plating Aluminum in China

Sunrise Metal offers premium nickel plating services for aluminum parts and many other metals. The process of nickel plating allows a very bright and lustrous finishing of the metal part and makes it corrosion resistant. Different nickel plating processes are carried out by our team of skilled professionals:

- Nickel plating aluminum

- Black nickel plating aluminum

- Electroless nickel plating

- Nickel coating

No matter which process you choose for the plating of your product, Sunrise Metal ensures superior quality and enhanced properties for it. Our qualified engineers will help you improve the operating efficiency of your aluminum parts through the process of nickel plating.

High Efficiency and Great Functionality Nickel Plating Aluminum Parts

Aluminum Nickel Plating Production Capability You Can Fully Trust

Sunrise can help you reduce the need for secondary processes and provide the most cost-effective solutions. We use the latest technologies and methods that are introduced in the world of metal plating services. At Sunrise, we are always working to optimize the process and to achieve even better results than before.

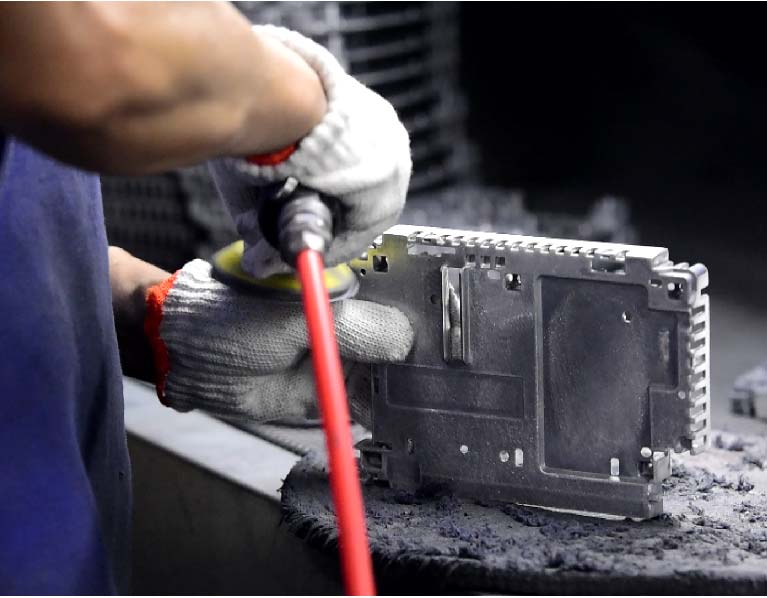

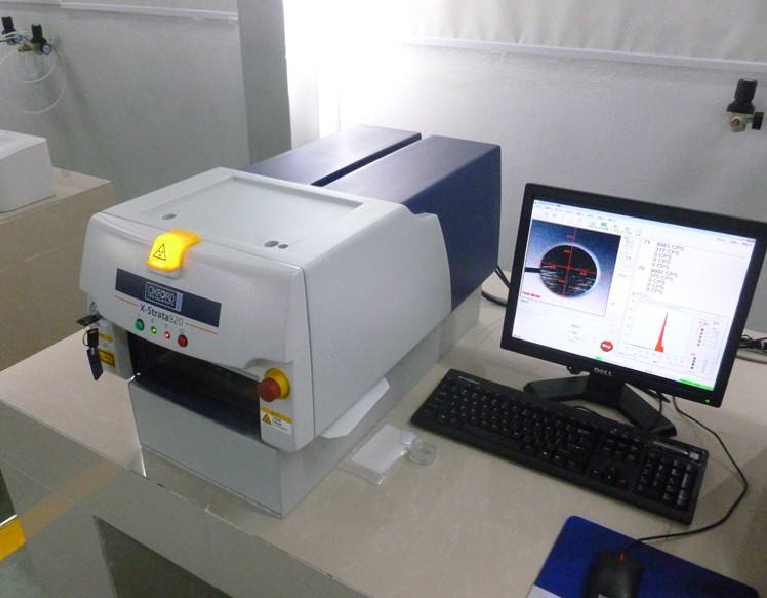

With the efficient production flows to the thorough inspection and high precision quality measuring lab in house, we support the nickel plating aluminum parts batch production with on-time delivery.

Qualifying and Managing RoHS and REACH for all nickel plating aluminum parts we provide.

Aluminum Nickel Plating Parts from Sunrise Metal's Fully Equipped Manufacturing Equipment

Recent Aluminum Nickel Plating Projects

Sunrise Metal develops complete solutions for aluminum CNC machined parts and aluminum die castings with nickel plating manufacturing for many years. For now, the projects we are completing with our customers are as follow:

- Advanced Equipment

- Premium Quality

| No. | Name | Stroke | Q’ty |

| 1 | Mazak 7-axis turning&milling Machine | Ø658*1011MM | 1 |

| 2 | Mazak /Hass 5axis CNC machine | Ø850/Ø600 | 4 |

| 3 | 3-axis CNC machine center | 2000*1500MM | 1 |

| 4 | 4-axis CNC machine center | Ø250*800MM | 8 |

| 5 | 3-axis CNC machine center | 1000*600*600MM | 20 |

| 6 | CNC Lathes | Ø320*800/Ø610*1000MM | 2 |

| 7 | Sodick Wire cutting Machine | 400*400*200MM | 3 |

| 8 | EDM machine | 500*400*400MM | 2 |

| 9 | Surface grinder | 600*300*200MM | 1 |

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

Get A Free Consultation

Receive advice directly from engineering consultants for your Aluminum Parts. Our suggestions and solutions are based on your CAD and Step drawings.

SUNRISE NICKEL PLATING ALUMINUM- THE COMPLETE FAQ GUIDE

Sunrise Metal is a certified manufacturer of aluminum die casting, aluminum CNC machining and zinc die casting with experience of more than 10 years. It is a one-stop service shop for all your die casting and surface finishing needs. Our experienced team has complete expertise in the production of the metal parts all the way to the nickel plating aluminum process.

- What is the nickel plating aluminum process?

- Which other metals besides aluminum can undergo nickel plating?

- What is the difference between nickel plating and electroless nickel plating?

- Why does aluminum require electroplating processes?

- Is nickel plating aluminum the same as anodizing aluminum? What are the differences?

- What are the advantages of nickel plating on aluminum?

- What are the basic requirements for aluminum nickel plating?

- Why is black nickel plating of aluminum preferred over other plating processes?

- In aluminum nickel plating, can nickel be directly plated over zincate aluminum?

- Is the nickel plating aluminum process possible after heat treatment? Why is it needed?

- What chemicals are used in aluminum nickel plating?

- What are the business applications of nickel plating aluminum services?

- What is the characterization of aluminum nickel plating?

What is the nickel plating aluminum process?

Nickel plating aluminum is a finishing technique that is applied to aluminum to enhance its properties. It is an additive process in which nickel is deposited on the aluminum product. The product is electroplated after cleaning it.

It is first immersed into an electrolytic solution to make it cathode and nickel forms on it by acting as the anode. The additional coating is formed for different purposes such as making aluminum corrosion-resistant or enhancing the appearance and sometimes is used to make it wear-resistant. The nickel-plated aluminum is sometimes further coated with other metals like gold, silver, chrome, or tin to give it a rich look.

Which other metals besides aluminum can undergo nickel plating?

Almost every base metal can be nickel-plated. The base metal is the one that can be found easily like copper and steel. The metals that are usually nickel-plated include the following:

Steel

Steel is the most widely used metal in the world. To enhance its properties, it is nickel-plated. Different forms of steel like stainless steel, are also nickel-plated. This combines the properties of nickel as well as steel to reduce the high rusting ability of steel. This process reduces oxidation on it and strengthens steel.

Copper

Copper and its alloys have many benefits wherever they are used. However, if enhanced, these metals can provide new properties. They are nickel-plated to make them work better. This not only increases their corrosion resistance but also the operating temperature.

Nickel-iron

Nickel-iron is the alloy of iron and is found in the planetary cores of earth. This alloy is mostly used in the production of batteries. When nickel-plated, this alloy shows an enhanced version of itself by becoming a better conductor.

What is the difference between nickel plating and electroless nickel plating?

Nickel plating is carried out by a process called electrolytic plating. Nickel electroplating is done by dipping the metal to be plated in an electrolytic solution. This makes the metal act as a cathode and nickel is dipped in the solution to form ions. These ions then form on the cathode and form a plating.

The plating of metal is not always done using this process of electrolysis. Electroless nickel plating does not require current to deposit a layer on the metal. It is amorphous and not crystalline, hence has good wear resistance. It uses a chemical solution to do so. A chemical reduction process makes the electroless nickel uniformly distribute over the metal. It is the phosphorus alloy of nickel and hence provides its properties too.

Why does aluminum require electroplating processes?

Aluminum and its alloys are used in many industries. This is because they provide many benefits and can even be enhanced using different techniques. The electroplating process is used for this purpose. Aluminum requires this process to

- Increase the electrical conductivity of aluminum

- Resist the corrosion of the metal

- Give aluminum a bright finishing

- increase the hardness of aluminum and its alloys

- Provide good lubricity

- Increase the solderability of aluminum

- strengthen the adhesion of aluminum

Many metals can be electroplated on aluminum like tin, nickel, silver, gold, and electroless nickel. This process can sometimes form an oxide on aluminum. Carrying out this process carefully can avoid this from happening.

Is nickel plating aluminum the same as anodizing aluminum? What are the differences?

Anodizing aluminum might sound the same as the process of electroplating aluminum but it has its differences.

Nickel Plating Aluminum

It is the process of coating aluminum with nickel. This process requires aluminum to be cathodized by dipping it into an electrolytic solution. This makes it attract the anodized nickel ions to form on aluminum.

Anodizing

Anodizing is the process of changing the surface of aluminum through an electrochemical process. It does not change the chemical composition of aluminum. It grows half into aluminum and half above it. This is done by sending an electric current through aluminum which forms tiny holes in the metal. Color pigments than take the place of the hole.

Nickel plating adds weight and outer dimension to aluminum and anodizing doesn’t. Anodized aluminum is not as strong as nickel-plated aluminum.

What are the advantages of nickel plating on aluminum?

Aluminum is nickel plated to improve its properties. Some of the advantages that it provides are

Corrosion resistance

Aluminum can easily oxidize when exposed to such environments. It can make the metal corrode. To make it resist that oxidization and corrosion, nickel plating is used. It forms a layer of nickel around it which does not corrode easily.

Brightness and luster

Aluminum loses its luster when it goes through many manufacturing processes. To provide it with additional brightness and luster, nickel electroplating is used. This process can even hide the polishing lines of aluminum and many other surface imperfections. It can also hide the impact of impurities if there are any.

Adhesion

This plating is strongly bonded to the surface of the aluminum. Unlike many other surface finishing processes that have weak bonds with the metal, nickel plating is quite strong.

What are the basic requirements for aluminum nickel plating?

Before aluminum is nickel-plated, it has to meet some basic requirements.

Cleaning

Before the process of nickel plating starts, aluminum is cleaned thoroughly from corrosion, dirt, or other defects. In order to do so, different techniques are used. The whole process of cleaning includes heat treatments, masking, etching, pickling, desmutting, and other techniques. Sometimes, acid is used to clean the surface of aluminum but it has to be washed completely before the process of nickel-plating starts.

Activating

To activate the surface of aluminum, different chemical activators are used. They are a solution of alkaline elements and salts. Aluminum is dipped into these solutions for one or two minutes at room temperature. Aluminum is then washed with water to clean off any remaining components on the surface. This is done to get exceptional results out of nickel-plating.

These steps make aluminum completely ready to go into an electrolytic bath of plating.

Why is black nickel plating of aluminum preferred over other plating processes?

Aluminum is a great receptor of black nickel plating. It is a secondary process to turn the surface of nickel-plated aluminum black. This process is preferred over many other finishing processes due to the many advantages it provides.

- Black electroplating provides better corrosion and wears resistance than other plating processes.

- It increases the electrical conductivity of aluminum.

- The surface of aluminum shows reduced reflectivity as compared to other plating processes some of which increase this.

- Black nickel-plated aluminum is more decorative than aluminum plated through other processes.

In aluminum nickel plating, can nickel be directly plated over zincate aluminum?

The Zincate process is used to prepare and activate aluminum for nickel plating. It is mostly made up of zinc oxide and sodium hydroxide. It is helpful in removing the layer of oxide from the surface of the aluminum. It also prevents the oxide from forming again on the surface.

Using this process, aluminum is made 100% ready and prepared for the process of electroplating. Aluminum can be directly dipped into the electrolytic solution. Sometimes the zincate solution is washed off of the aluminum surface but it is not really necessary.

The zincate solution makes aluminum ready to get nickel-plated. More zinc plating allows better coverage of nickel onto the surface of aluminum resulting in a uniform surface.

Is the nickel plating aluminum process possible after heat treatment? Why is it needed?

Aluminum is nickel-plated after it is completely cleaned and activated. The process of cleaning involves washing it with acid and cleaning it using etching and heat treatment.

Heat treatment is required to remove any deposited material from the surface. The heat treatment of aluminum might cause some problems. It can result in the formation of an oxide layer on the surface. Once this layer forms, it is not possible to electroplate aluminum. To make aluminum free of this oxide layer, it is very carefully heat treated.

Heat treatment is not only needed for the cleaning of the aluminum surface but also used after it is electroplated in order to increase the hardness of the metal.

What chemicals are used in aluminum nickel plating?

When aluminum is nickel-plated, it is required to have certain temperatures, density, and PH value. After these requirements are met, it is dipped into the bath of different chemicals. These chemicals, when combined together, provide aluminum with a cathodic nature. The bath is of two types. These two types are made using different compositions of the chemicals included. Nickel plating utilizes the following chemicals

- Nickel sulfate

- Nickel Chloride

- Boric acid

When the quantity of nickel sulfate is lowered and that of nickel chloride is increased, it forms a solution that makes aluminum semi-bright. This is made to provide less luster on the surface of the aluminum. The temperature to start the nickel plating process must be around 40-65 °C. The cathode current density should be 2-10 A/dm2 and the pH of the solution should be 4.7-5.1

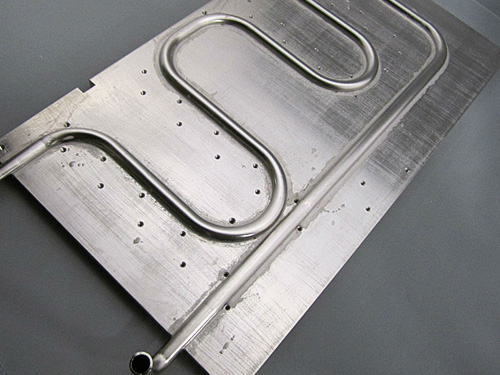

What are the business applications of nickel plating aluminum services?

Nickel-plated aluminum is widely used in many different industries. This helps make aluminum corrosion-resistant and wear-resistant. It also brightens up the plated aluminum and allows its use in many different places

Medical

Nickel-plated aluminum is stronger than that of non-plated aluminum. This strength of the metal is utilized in the medical industry where durability and strength are the major requirements.

Electronics

Nickel-plated aluminum is used in the manufacturing of different electronics which are used everywhere in our daily life. Electronic in our homes and other industrial areas make use of this process to make them wear-resistant.

Telecommunication

The process of nickel plating gives the metal a matte finish. This matte finish metal is used in the telecommunication industry and computer devices industry for various purposes.

Automotive

The lustrous and more bright plated aluminum is called decorative nickel-plated aluminum. This aluminum is used to give an aesthetic appeal wherever it is used. Therefore, it is used in the exterior of auto parts such as bumpers.

What is the characterization of aluminum nickel plating?

The aluminum nickel plating allows the formation of a nickel layer on aluminum and its products. Different characteristics of the process are shown during the formation of this layer:

Deposition rate

The aluminum acts as the cathode and nickel ions are anode that gets deposited on the surface. The rate at which nickel is deposited on the aluminum metal is directly proportional to the current that is passing through both of them. All of the nickel in the form of ions is deposited on aluminum as long as the current is passing through it.

Current Efficiency

The current passing through the electrolytic solution is quite efficient. It is completely utilized by the process and only a very small fraction of it is utilized in other electrochemical processes. These processes take place with the process of electroplating and cause ripples and bubbles in the bath.

Coating thickness

The thickness of the nickel that is deposited on aluminum metal is dependent upon the time it was allowed to settle on aluminum as well as the amount of current that passes through them. When the aluminum component has a complex shape, the deposited metal is not uniform and requires many different processes to make it uniform.