SUNRISE QUALITY SYSTEM

Sunrise implements a Quality Management System that helps to coordinate efforts in quality assurance. This involves directing all activities of process, technology, material and method to meet customer and regulatory requirements.

Sunrise’s quality capability works ahead of time and removes all defects which may be caused in design and operations. Processes and controls are improved in line with international standards, programs and instruction manuals.

We constantly strive to improve product quality and service level by constantly reviewing processes and customer needs.

This standard is a quality management system standard applicable to the regulatory environment of medical devices.

- Put more emphasis on the requirements for documentation and records on the basis of ISO9001.

- More focus on the design and development, production, storage, installation, service for medical devices.

- Stress the requirements for communication and reporting with regulatory agencies.

- Emphasize the risk-based approach to the management process.

Specifies requirements for a quality management system for an organization in the following ways:

- Strengthen the ability to deliver high-quality products

- Meet all relevant regulatory and statutory requirements

- Achieve high levels of customer satisfaction and develop relationships

- Strengthen quality management systems and promote corporate efficiency

- Enhance quality awareness of all employees and improve corporate culture.

The International Standard, combined with applicable customer-specific requirements, defines the fundamental quality management system requirements for automotive production,service and/or accessory parts organizations.

Companies must strive to achieve:

- Continuous improvement in processes and quality standards

- Regular efforts to achieve customer satisfaction with products and services.

- Prevent product defects and reduce non-conforming products.

- Promote procedures to reduce change and waste

- Improve production efficiency and train all staff accordingly

PREMIUM LABORATORY FACILITY

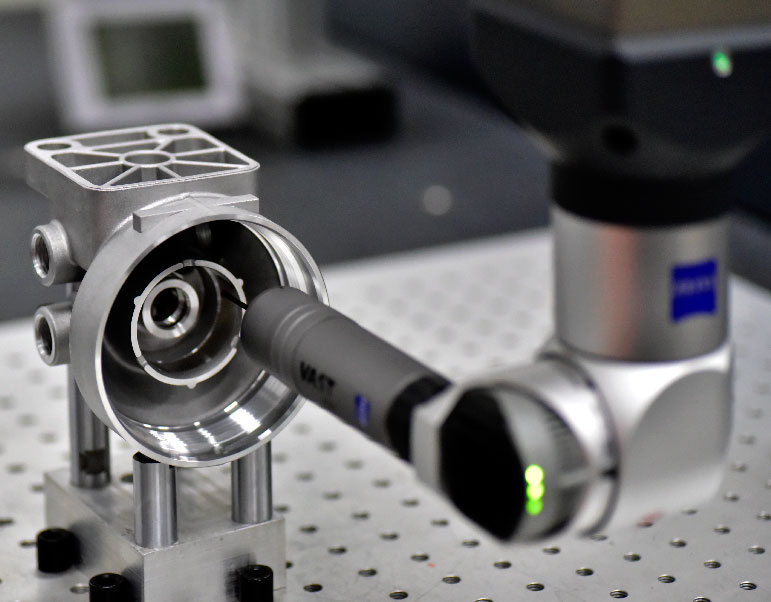

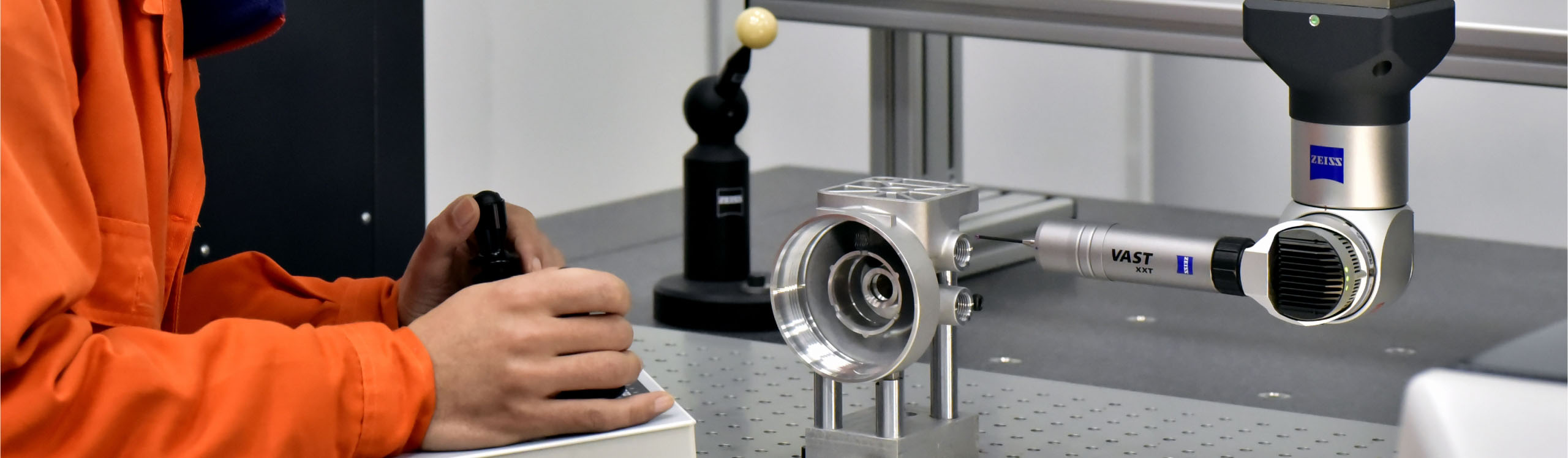

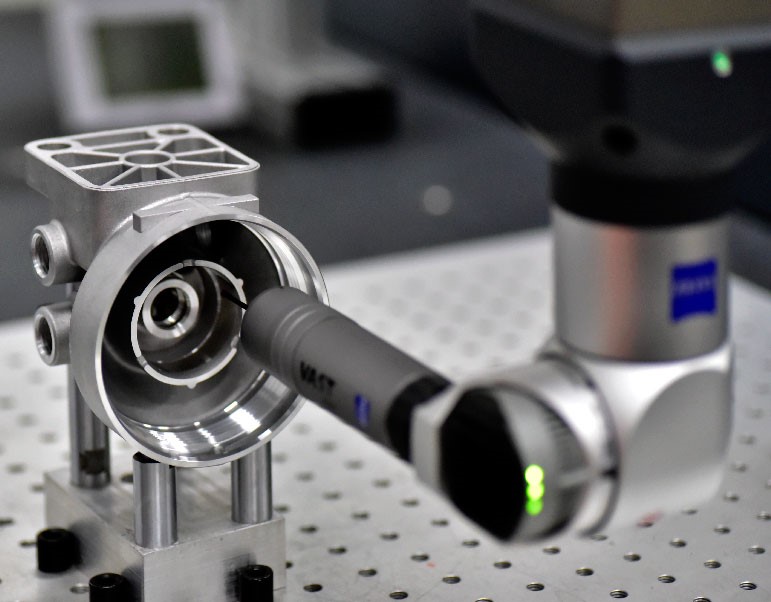

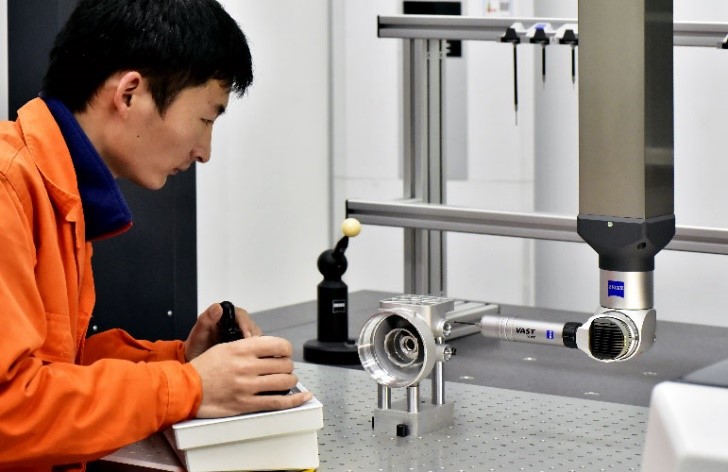

Sunrise has invested in advanced QA Test equipment to maintain accuracy and completeness of measurement. Equipment includes Coordinate Measuring Machine with Zeiss brand, X-ray detection machine, and more as shown below.

SUNRISE QUALITY SYSTEM CAPABILITIES

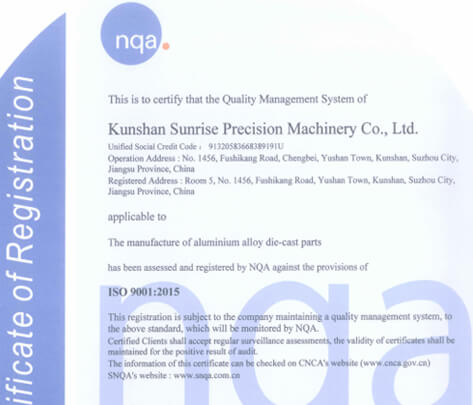

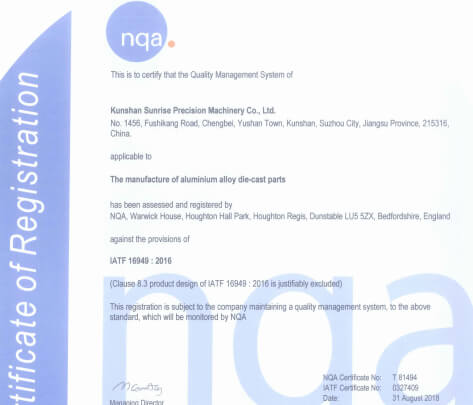

Sunrise Metal has been in the market for more than 10 years serving each client with outstanding services. Being an ISO 9001 & IATF 16949 certified manufacturer, Sunrise is a trusted solution for all die casting solutions, dedicating its service to over 500 loyal global clients. We have passed customer audit systems such as the SGS system to achieve high levels of customer satisfaction.

As an authority in the die casting manufacturing industry, we actively engage in activities that help fulfill customer expectations. Our company’s vision as the leading aluminum die casting manufacturer in China is safeguarded by the first-rate inputs from our technical teams and modern equipment.

Upholding Product Quality Standards

Sunrise Metals produces quality enriched die casted products that are manufactured with precision and accuracy. In addition, we invest in the technology and materials used during our processes to eliminate any defects that may appear in the final products.

We assure strong material integrity and smooth finishes for all our products. Our manufacturing capabilities have made the production of customized die casted parts possible for hundreds of global clients. Methods and process controls are established so that product quality and service level is maintained at all times.

Sunrise Metals provides superior services to the clients in the shape of their products. Our aluminum die cast products are efficient and decrease the cost and labor of connected industries. This is due to our utmost priority on high serviceability.

The products manufactured under Sunrise Metals possess the superiority in following aspects

- Dimensionally stable and accurate parts that increase process efficiency

- Durability and resistance to heat in order to improve lifespan

- Wide variety of texture simulated at the surfaces of our die casted products

- Use of high-quality material to develop products without impurities

- Ability to manufacture complex products with quality and efficiency

Customer Satisfaction and Engagement

The company’s philosophy to create value-added quality products guides us in our path to becoming industry masters in what we do. Adoption of a win-win approach has been most fruitful for us in terms of winning over customers. We don’t just provide them with the best products, but also offer flexible business terms to accommodate their evolving needs.

This is especially true for small scale clients who demand a mix of quality and cost-effectiveness. Most other die cast suppliers either do no possess the capacity or fail to entertain small orders in while mitigating costs. At Sunrise, we believe in catering to manufacturers of all backgrounds in order to expand the value that we bring to the community.

Through maintenance of international quality standards, we seek to maximize customer satisfaction. We ensure that product safety requirements are met through regular staff trainings, as well as cost and efficiency savings.

Sunrise Quality System: ISO 9001 and IATF 16949

Sunrise is ISO 9001 and IATF 16949 certified. These are international standards that confirm our claims about quality and resource management. Before you place your trust in us, here’s a summary of these certifications, to help you understand how best you will be served.

ISO 9001

This is an international standard that specifies all kinds of requirements for a Quality System. It is the world’s most followed and recognized system that guides companies in serving their customers and stakeholders.

The framework entails the following features:

- Meeting regulatory, statutory and customer requirements to ensure service quality

- Strengthen measures in quality management and promote corporate efficiency

- Quality awareness and training of employees to maintain corporate culture

- Organize company processes and continually improve their efficiency

- Documenting information and planning related to quality management systems

- Management of human resources and improving work environment

- Product realization step from design to the delivery of quality products

- Internal audits and preventive actions that improve quality management systems

IATF 16949

This international standard is a technical specification for quality management systems in the automotive sector. The aim is to enable quality products to be produced for automotive customers worldwide.

The IATF 16949 is a supplementary standard used in conjunction with ISO 9001, where the latter provides base requirements for a QMS. At Sunrise, we follow a process-based quality management system that requires ongoing improvements, variation control, and defect prevention. We do this with the utmost ideal of achieving efficiency for our customers, and providing consistency and high product quality to all our customers.

Maintaining both of these certifications has awarded us with outstanding features as an international supplier of aluminum die casting. We are:

Credible:

A reputable company with notable clients in the automotive industry, along with key sectors such as telecommunication, marine, and others. Customers who value quality come to us and are fully satisfied with our standards and applications in complex manufacturing processes.

Leaders:

Strong believers of improvement and customers are never disappointed by out commitment to quality. We have high customer retention rates and believe in keeping our customers happy in the long run by customizing and accommodating at all stages.

Strategists:

The company’s main focus is not only driving sales without a business goal. We have adopted a growth approach that drives us to find cost savings for ourselves and our clients. Our supply chain is constantly rechecked to find ways to reduce waste and fuel efficiency.

Researchers:

Capable teams at Sunrise are following evidence-based systems to make decisions about processes and management output. This informed approach keeps us one step ahead of the curve and we never fail to deliver.

Recruiters:

Staff members, managers, inspectors and engineers all learn to work in collaboration with each other. They are made to understand how quality is deeply linked to their expertise and performance. Regular encouragements and guidelines are provided to keep everyone on track and happy.

Quality Control and Management Systems

Sunrise Metals believes in providing top notch services to the clients and have assured customer protocol. Our teams are trained to provide trusted services and deliver quality products. We work on standards that assure the customer supplier relation remains trusting. In addition to these services, Sunrise Metals assures customer satisfaction as this is our top priority.

Following ISO 9001, Sunrise has organized quality management systems that lead to customers that are satisfied and managers who are well-equipped to continuously improve quality. We work tirelessly to towards cost-effectiveness and productivity, while promoting a great deal of professionalism.

We provide the services without causing any delays. Therefore, we provide:

- Fast prototyping

- Fast mold

- Fast production

- Fast delivery

Sunrise Metals focuses on the quality of products, therefore continuous research and study is carried out at our company to attain customer satisfaction. Different instruments and equipment are used to ensure quality in our products and quality checks are made at every step of the manufacturing process.

Strict quality plans and production controls are put in place in line with ISO systems for PPAP, SPC and APQP. This includes improving the efficiency of quality management systems and making sure that compliances are consistently made in line with customers’ requirements. Timely preventive actions are taken by analyzing recurring methods and having corrective actions ready before hand.

During the design process for example, quality systems at Sunrise work ahead of time to mitigate the chance of defects caused by intricate designs. Out fabrication is in line with ISO standards, along with work instructions to improve process control.

Sunrise has invested in advanced quality assurance testing equipment to ensure that all measurements are accurate and complete. Some of the equipment used at Sunrise Metals for this purpose are:

- X-ray detector: to test parts of defects like porosities

- Cleanliness tester: to test manufactured parts of any potential impurities

- Zeiss CMM: to measure the accuracy and completeness of product with Coordinate Measuring Machine

- Digital Caliper: to take measurements of the products precisely

- Salt Spray tester: to evaluate corrosion resistance of the metal part.

- Thickness tester: to measure thickness of parts accurately

- Colorimeter: to measure color of the metal parts.

Sunrise Metals offer its services in major and minor aspects of manufacturing metal parts. Utilizing our services can be beneficial to the customers as our products are both high quality and economic. Our fast services will speed up your time to market your product.

Our expertise in the field assure hassle free production and dealing with a foremost focuses on quality of the product and customer satisfaction. Our services proudly ensure both. Providing services to our global customers and their satisfactory reviews motivate us to improve our work with the time.

Engineering and Quality Control Team

Sunrise Metals provides regular training to the engineering teams to receive more advanced solutions. The teams are always up to date with the latest trends and technologies. Our engineers guide each client and assist them while customizing the parts. This proactive approach to meeting client expectations is appreciated by trusted clients who are assured that we will go the extra mile in determining their needs are met.

A key factor in the development of our quality control teams is relationship management, which allows us to optimize performance and keep all interested parties engaged. Not only does this maximize productivity from each team, it leads to recognition and empowerment of individual players. The end result is a strong team and a long-standing company, ready to deliver the best.

The team works with component production and quality strategy and achieves improved engineering analysis. They put their efforts in all the phases of manufacturing starting from designing to end of production to finishing of the product. Our employees work in different roles including research and technology.

Our quality control teams work with knowledge and ethics to provide our customers with a high-quality product as well as a rich experience. Inspectors, engineers and managers are authorized to provide specialized advice in order ensure that quality standards are not compromised.

Why Should You Choose Sunrise Metal?

Sunrise Metal has long been known for maintaining top industry standards in die casting products, tooling, machining and furnishing. We have streamlined our processes and manage costs for a wide range of products. We cater to automotive, marine, telecommunication, and other general sectors, and have secured loyal customers across the board.

From mold design to aluminum component manufacturing and surface finishing, our skilled workforce will deliver a world-class experience. Our alloys are stable and durable, and the parts we manufacture are cost-effective. CNC machining is state-of-the art, while still maintaining costs that keep you going.

At Sunrise, we believe in a growth mindset and adopt approaches that improve our organization’s processes piece by piece. We never let an opportunity go by without exploring it to achieve efficiency.

Our product quality is unmatched, with high emphasis on avoiding defects and waste in the supply chain. Time and money are of immense importance to us and our customers, and every member of our company, from engineers to managers, make sure that proficiency levels are always on the rise.

The integration of international standards and certificates stands proof of our commitment to quality management systems. As a long-term manufacturer, we have invested in an organizational structure that benefits employees and customers alike.

Our aluminum die casting process is a top-grade system that is open to all types of customers from small to large orders, and with varying complexities. With high precision and complex geometry, we produce light-weight, cost-effective aluminum die casting parts. We strive for the best Research & Development capabilities to find innovative and turnkey solutions for prototyping, machining and assembly.

Rest assured, with Sunrise Metal, your path to success is defined. We are a call away from determining the best solution for your manufacturing needs, at the most reasonable costs in the market. Get in touch with problem solvers and design experts, and turn complex specifications into practical applications. Pose your problem now, and let us offer a solution!