TRUSTWORTHY MEDICAL DIE CASTING SUPPLIER

In the medical device industry, its projects normally mean low volume & extremely high requirements on function and visual surface. Most Aluminum Die casting suppliers don’t prefer such kinds of projects. But to Sunrise Metal, after many years of practice and hard work, we have developed a mature system to make medical die-casting parts.

Our dedicated team can succeed in your business with:

- We help improve your product yield and smooth mass production by DFM & PFMEA Evaluation.

- 10+years experience in medical die castings manufacturing, we have valued customers like Mindray, Analogic, etc.

- Strict quality control for your products based on ISO9001 & ISO13485 systems.

- Offer 1-stop solution service including prototyping, tooling, die casting, precision machining, and surface finishings.

ONE STOP DIE CASTING MANUFACTURING CAPABILITY

Offer a 1-stop solution service, including prototyping, tooling, die casting, CNC machining, and surface finishings.

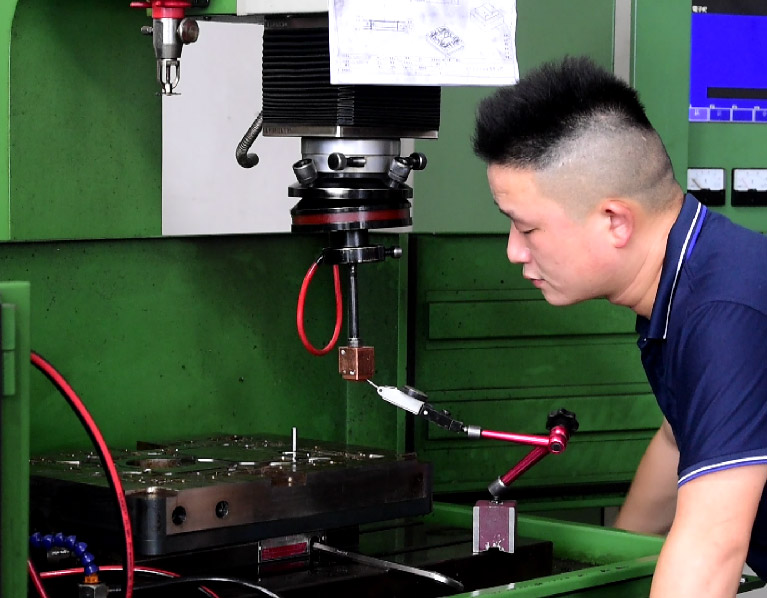

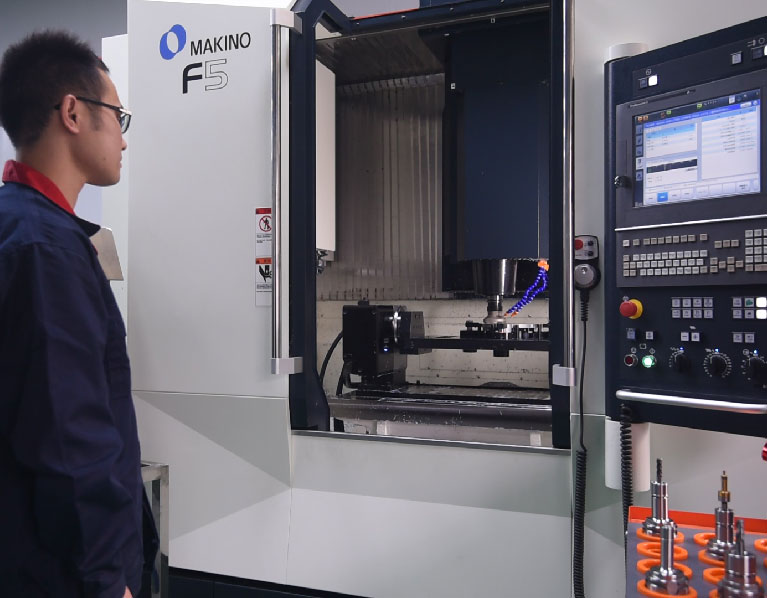

Good at high precision die casting & machining parts manufacturing, up to the accuracy of 0.005mm.

Continually investing in high tolerance equipment based on orders request and quality requirements.

STRONG ENGINEERING & QC CAPABILITY

RECENT MEDICAL ALUMINUM DIE CASTING PROJECTS

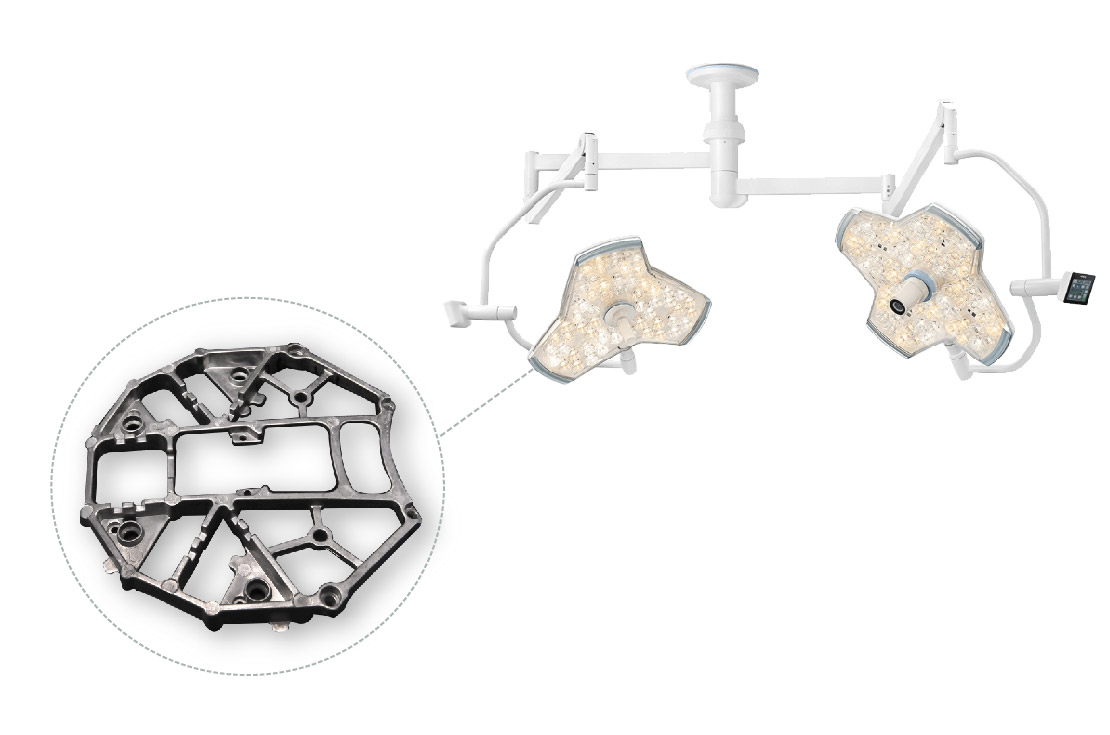

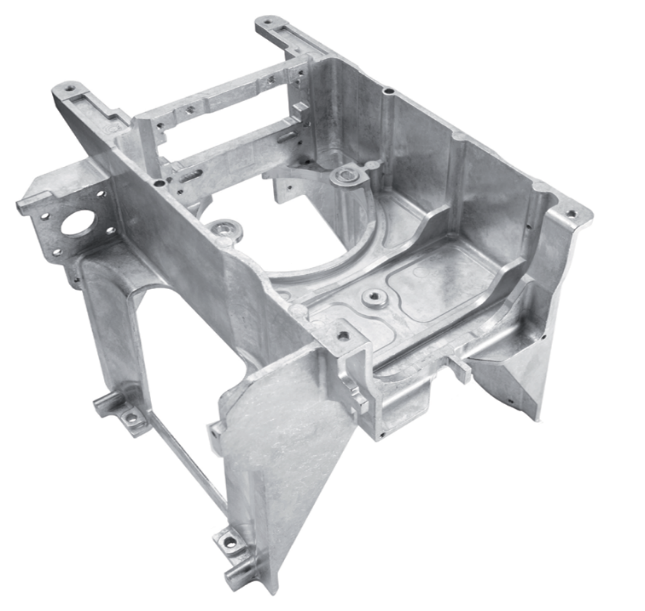

Part Name: lAMP MOUNTING BASE

Material: ADC12

Size: 551*416*70 mm

Weight: 1480g

Machine Tonnage: 800T

Surface Finish: Powder Coating

Production Process: Die Casting–Trimming–Deburring

–CNC Machining–Chromating–Coating–Screening–Packaging

Applied Industry: Medical

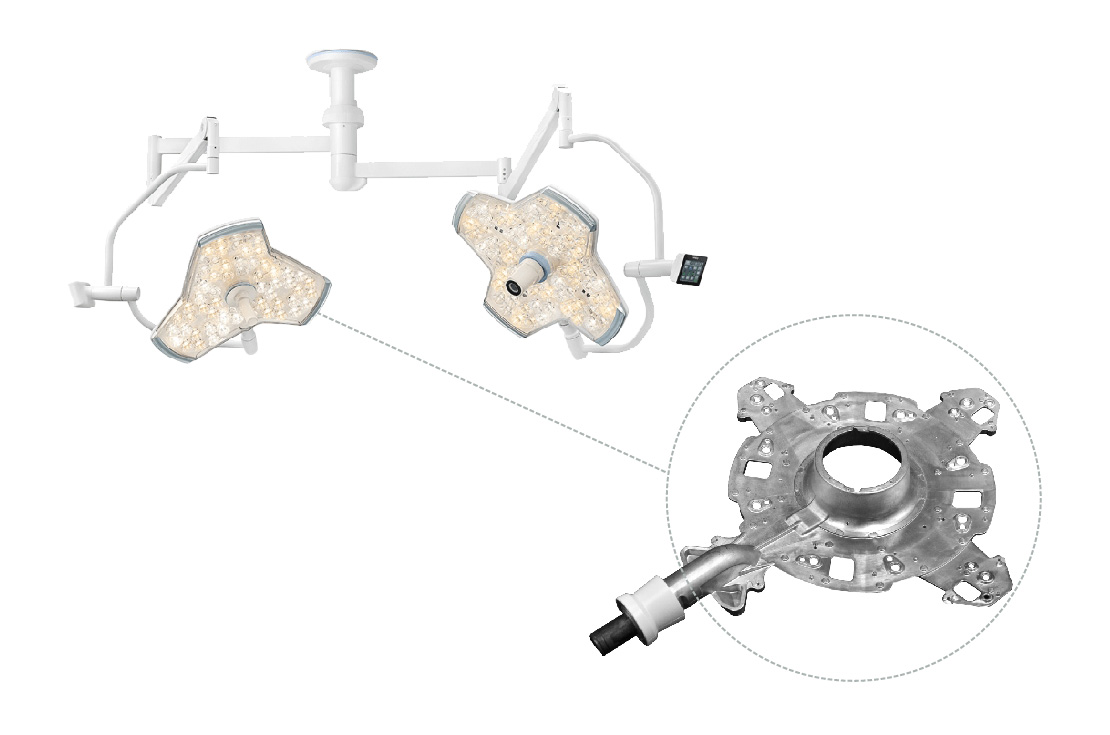

Part Name: HAND SHANK

Material: AlSi12

Size: 357x222x44 mm

Weight: 773g

Machine Tonnage: 500T

Surface Finish: Chromating

Production Process: Die Casting–Trimming–Deburring

–CNC Machining–Assenbly–Powder Coating–Liquid Painting–Screening–Packaging

Applied Industry: Medical

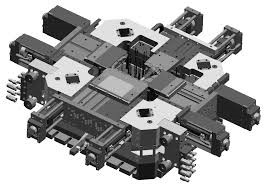

Part Name: BRACKET OF OPERATING LAMP

Material: AlSi12

Size: 219.7*209.5*27.2 mm

Weight: 330g

Machine Tonnage: 280T

Surface Finish: Chromating

Production Process: Die Casting–Trimming–Deburring

–CNC Machining–Chromating–Screening–Packaging

Applied Industry: Medical

Part Name: SCANNER BRACKET

Material: AlSi12

Size: 230x85x80 mm

Weight: 420g

Machine Tonnage: 400T

Surface Finish: Chromating

Production Process: Die Casting–Trimming–Deburring

–CNC Machining–Chromating–Screening–Packaging

Applied Industry: Medical

MEDICAL CASTING:

THE COMPLETE FAQ GUIDE

Medical Casting provides a wide diversity of exceptionally high-quality casting services for medical device parts and other equipment.

Using Aluminum in Medical Casting is preferred because it can save money, increase production capacity, and experience a fast return on investments.Medical Casting parts developed by our industry features superior strength, supreme rigidity, and are light in weight.

However, all of these are considered as essential characteristics in modern medical devices and equipment.

- What is Medical Casting?

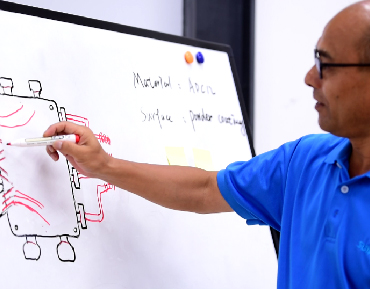

- What are top-notch engineering and design skill in Medical Casting?

- How to implement the QA (quality-assurance) measurements in Medical Casting?

- What is the part of automation in Medical Casting?

- What are the top products of Medical Casting?

- What alloys are used for Medical Casting?

- What is the importance of Medical Casting regarding medical equipment and devices?

- What is the biocompatibility in medical Casting of medical equipment and devices?

- How can surgical devices be specialized through Medical Casting?

- What role Medical Casting plays for therapy and diagnostic devices?

- What is the importance of Medical Casting?

- How is Medical Casting beneficial in electronic medical devices?

- Why prefer Aluminum in Medical Casting?

- What are the benefits of Medical Casting?

- How to test the quality of Medical Casting products?

- What are the uses of Aluminum in Medical Casting?

- What are the medical technology requirements for Medical Casting?

WHAT IS MEDICAL CASTING?

When it comes to the medical industry, no compromises are allowed.

By and large, Medical Casting – either incorporated with the inside of medical accuracy instruments or gave a galvanic surface – empowers specialists to focus totally.

Examples of some popular applications of Medical Casting are defibrillators and blood pressure, monitors.The exactness and precision with which medical equipment and hardware must capacity for all time is a foremost trademark that qualifies a material for medical innovation.

WHAT ARE TOP-NOTCH ENGINEERING AND DESIGN SKILL IN MEDICAL CASTING?

Manufacturing or producing top-quality and excellent die casting medical devices parts or equipment for products such as;

Pacemakers, CAT scanner parts, monitoring systems, and ultrasound system particles being with efficient engineering and design.

Growing high-accuracy die casting medical gadget parts that meet the specific client determinations is the center reason for our industry, and our engineers are best in it.Our administrations incorporate rapid prototyping and die casting medical items and tooling design that bring about an amazing item without fail.

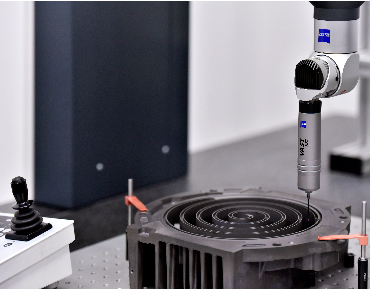

HOW TO IMPLEMENT THE QA(QUALITY-ASSURANCE)MEASUREMENTS IN MEDICAL CASTING?

In medical Casting, quality should be a priority for both industry and customer.

The quality of the yield items is ultra-significant with regards to die-casting for medical equipment, parts, and items.

When all is said in done, QA (quality assurance) ought to consistently be at the highest priority on your rundown of needs.

Our industry applies an assured quality process that incorporates careful and accurate planning.

The use of delicate and accurate measuring equipment and the strict and essential adherence to quality-control steps in-order-to ensure the quality and accuracy of the finished product meets the customer/industrial expectations.

Our engineers carefully monitor each aspect of the medical casting process.

WHAT IS THE PART OF AUTOMATION IN MEDICAL CASTING?

Near us, medical Casting is considered as a top state-of-the-art facility featuring advanced automation.

Besides, automation is a basic piece of the medical casting process for medical die casting gadget parts, and medical die casting gears.

In any case, High-tech and top-quality tooling and a wide assortment of automation/mechanized processes that help to give the superior blend of;

- Efficiency

- Accuracy/accuracy

- Consistency

- Its diminished process and assembling costs

Our industry is capable of accommodating low-volume & high-volume medical casting manufacturing processes with accuracy and ease. Furthermore, human intervention occurs if needed to ensure the execution of all die casting procedures and techniques with the highest degree of accuracy and is an example of perfection.

WHAT ARE THE TOP PRODUCTS OF MEDICAL CASTING?

The following are the top products related to medical Casting and can be achieved in the shape of an output of the therapeutic casting process.

The mentioned process could be through prototyping/rapid-prototyping and die casting:

- Pieces of equipment support the medical monitors

- Parts operating robots

- Dialysis Equipment

- Ophthalmological Equipment

- Oxygen related equipment

- Insulin and IV pumps and parts/products

- DNA Sequencing Equipment

Our industry is capable of producing customized and intricate designs efficiently and accurately.

WHAT DIE CAST ALLOYS ARE USED FOR MEDICAL CASTING?

The most popular and commonly used alloys for medical Casting are of aluminum, aluminum-silicon, and aluminum-silicon-copper alloys, and accessible from them are the following:

A380:

A380:

It is a kind of aluminum alloy and contains an exceptional combination of casting, mechanical, and thermal properties.It’s the most common alloy and exhibits a subtle amount of fluidity, pressure-tightness, and resistance from hot cracking.

A380 has quite a good machinability, which means a perfect alloy for medical Casting.

383 (ADC12):

383 (ADC12):

Sometimes, need comes for an alloy if medical device components are highly intricate, and ADC12 is the right alloys because of its excellent mechanical, exceptional physical properties, and dimensional stability.

Alsi12:

It is a mixture of aluminum and silicon and is known for its unique mechanical properties and suitable as brazing alloy with an exceptional amount of flux.

AlSi9Cu:

AlSi9Cu:

It’s an aluminum, silicon, and copper mixture and so unique that only specialized industries used them.

It has some of the most robust mechanical properties and solutions to manufacturing/producing lightweight medical and automation parts. It has excellent use in medical Casting.

WHAT IS THE IMPORTANCE OF MEDICAL CASTING REGARDING MEDICAL EQUIPMENT AND DEVICES?

The most common challenge with graphing and designing medical devices is striving for the final output products that define;

The clinical needs, human error, and environmental and, most importantly, patient safety.

The design of these devices is with the addition of technology becoming more and more complex as industries pay close attention to details.What’s more, the customer hardware industry while thinking about progressions and uniqueness in design and convenience.

In medical Casting – miniaturization is turning into a pattern in medical gadget design, and speed to showcase is considered as the key upper hand for item launchers.

Our industry is the best when it comes to medical Casting and provides precision medical casting components for medical devices.Medical equipment that addresses the issues of numerous customers, conditions, and patient changeability.

WHAT IS THE BIOCOMPATIBILITY IN MEDICAL CASTING OF MEDICAL EQUIPMENT AND DEVICES?

Aluminum is not the only choice when it comes to manufacturing medical Casting, where medical devices must interact with tissues/bodily fluids.

A vast majority of special casting alloys, which are considered as the best use for medical Casting, can be applied in the casting process to meet testing and validation/verification required by a third party or the industry/clients.Alloys similar to silicon and copper can be mixed with aluminum and can give a solid alloy as output.

Our industry offers a wide scope of medical casting alloys, so our customers never need to restrict the material decision.

HOW CAN SURGICAL DEVICES BE SPECIALIZED THROUGH MEDICAL CASTING?

Surgical devices and equipment can be specialized and verified as the field of medicine and doctorate.

Generally, aluminum alloys are thought to be the only materials that can meet FDA approval for manufacturing and producing bio-compatible medicine/surgical devices.

At present, a vast majority of parts and components that are part of medicine/surgical devices are die casting.

Aluminum die-casting immediate process and product cost saving through medical Casting for medical device facilities.

Our industry is master in producing these components and parts, and handle complex components securely, and cast them accurately.

WHAT ROLE MEDICAL CASTING PLAYS FOR THERAPY AND DIAGNOSTIC DEVICES?

When it comes to the medical Casting – medicine field, intelligent therapy, and diagnostic devices are helpful in:

- Screening

- Access

- Diagnose patients

And that’s why it must be designed with a perfect high level of sophistication for regular, easy, and effective use in the lab, hospital, clinic, or at the patient’s home.

For industries, offering state-of-the-art equipment and tools which contain an ergonomic design for an immersive output means considering:

- The toughness of the medical equipment

- Ergonomic designs enhance the appearance

- Weight in addition to function

Our industry’s exceptional components offer a variety of elective options to exceed the essential requirements for:

- Design Flexibility

- The material in use

- Precision in production and Casting

- Surface Finishes

WHAT IS THE IMPORTANCE OF MEDICAL CASTING?

Medical Casting is the most major industry, and it continues to play a critical role in the success of global manufacturing through the production of high-quality Casting and support of key industry metrics.

The fact is that medical Casting is used in approx. 75% of the finalized manufactured products.

The medical casting industry produces over one-third of all castings. In the medicine field, medical casting applications include;

- Portable medical monitors

- Dental X-ray units

- Hospital electronically operated beds

- EKG machinery

- Ultrasound equipment

- Hand-held medical devices

HOW IS MEDICAL CASTING BENEFICIAL IN ELECTRONIC MEDICAL DEVICES?

As electronic medical equipment and parts becoming increasingly sophisticated, enhanced, and powerful, so do the electronic components/parts they contain.

Keeping the environmental and internal temperature of these electronic devices fresh is vital in terms of their reliability and lifespan enhancement.

High-performance and ultra-accurate heat sinks are a great help to prevent electronic devices from overheating, damaging, lose accuracy and performance, or ruining the medical equipment completely.

Our process of medical Casting is exceptionally durable and can integrate heat sinks with their product design.

Essential and crucial requirements with the need for heat dissipation have made us the source of the medical casting device components.

WHY PREFER ALUMINUM IN MEDICAL CASTING?

Aluminum Medical Casting offers a vast amount of benefits over other techniques in medical/medicine facility.

Aluminum alloys, which are used in the majority of medical casting work, have an exceptionally excellent strength-to-weight ratio.These alloys are robust and lightweight, which makes them ideal for mobile medical equipment, where stability is essential.

Aluminum Medical Casting is a cost-effective process, with rapid set-up times.

Casting is ideal for producing complex shapes correctly, which is an essential requirement nowadays.

Aluminum for Casting is preferred for medium- to high-volume production.

WHAT ARE THE BENEFITS OF MEDICAL CASTING?

When ordering and designing a medical or surgical device, consider medical Casting (die-casting) as the process of choice.

- Doing so enables you to have the following unique and precious benefits from medical Casting:

- Enables to the design of complex net-shape parts and components

- Consistent high-quality over high-volume

-Cost-effective

-High-volume production rate

-Achievable tight tolerances as cast

-Medical Casting – Cast housing is extremely durable

- Provide the option of integration of head sinks within the product design

- It offers a wide variety of surface finishes from high-specification plating to products finishes

-Precise and value engineering achieve process and production cost saving

-Minimal draft angles on interior features

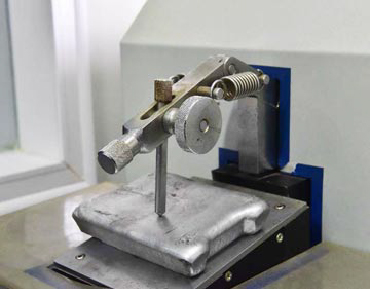

HOW TO TEST THE QUALITY OF MEDICAL CASTING PRODUCTS?

Testing the medical casted products is a critical part of the aluminum medical casting process to check each component meets the specifications defined.

However, vital to adhere to the high-quality standards essential in the medical sector.

The most critical quality assurance measures got used following and in a sequence:

-Casting Pressure Testing

-Part Finishing and Plating

Surface Finishes

- Vibratory Deburring

- Shot Blasting

- Polishing

- Plating

- Finishing Classes

- Utility Grade

- Functional Grade

- Commercial Grade

- Consumer Grade

- Superior Grade

WHAT ARE USES OF ALUMINUM IN MEDICAL CASTING?

At present, hospital ward and operating theaters are filled with the medical equipment and fittings manufactured using medical Casting – from surgical instruments to medical monitors.

From the very beginning, aluminum alloys are used in medical casting to get precise outcomes as a perfect product.

Industries are producing aluminum medical castings for clients/hospitals in the preventive/medicine section for many years.

The high-precision and elegant aluminum medical castings produced in industries meet the exacting manufacturing and ISO standards and essential safety requirements demanded by the environment and living in this section.

WHAT ARE THE MEDICAL TECHNOLOGY REQUIREMENTS FOR MEDICAL CASTING?

When it comes to accuracy and precision, medical Casting can address hygiene regulations for parts/components that come into contact with humans and their surrounding environment.

Such components must withstand the regularly base used of detergents/disinfectants without impairing appearance/functionality.

The vast majority of surfaces achieved with medical Casting means a suitable solution always can be found, even in demanding conditions and environments.

However, medical casting parts are used in an aggressive environment and intended to meet essential requirements. What it requires is the following:

- High-quality medical Casting is a core prerequisite for achieving perfection in surfaces.

- Hand-h medical devices, such as cameras that doctors move inside patients’ mouths or appliances used to measure the human eye, must be well-balanced, comfortable, and reliable.

- Protection against radiation is a crucial one. Led medical devices, such as cameras that doctors move inside patients’ mouths or appliances used to measure the human eye, must be well-balanced, comfortable, and reliable.

- Protection against radiation is a crucial one.