Die Casting Housing

As a distinguished manufacturer in die casting industry, Sunrise offers a premium-quality range of aluminum die casting parts for various industries.

We are engaged in developing components to be used in both small and large scale industries. It can be used in Power Tools, Consumer Electronics, Flow Control System, Ultrasonic Scanner, Textile, as well as many other general applications.

General die casting products have an extremely lightweight design, while at the same time the ability to withstand high pressures, temperatures, and extreme weather conditions. Looking learn more about aluminum die casting.

Sunrise Die Cast Housing Manufacturing Capability

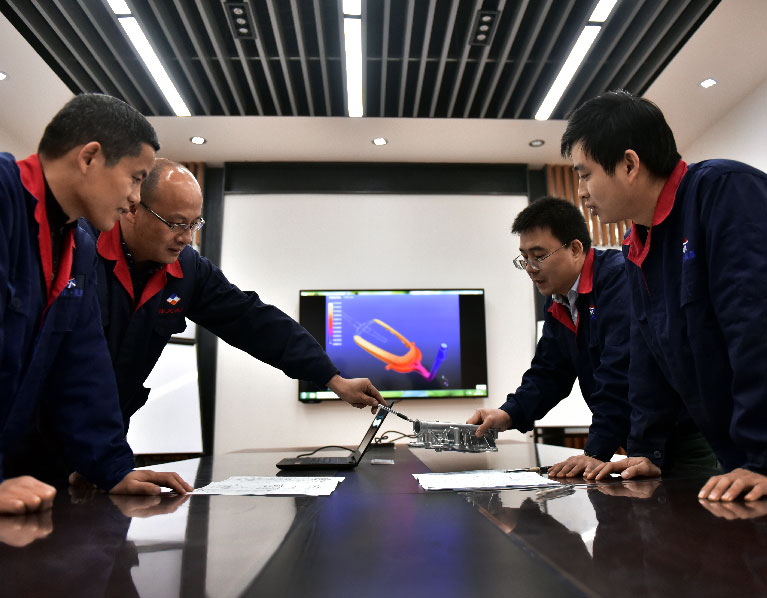

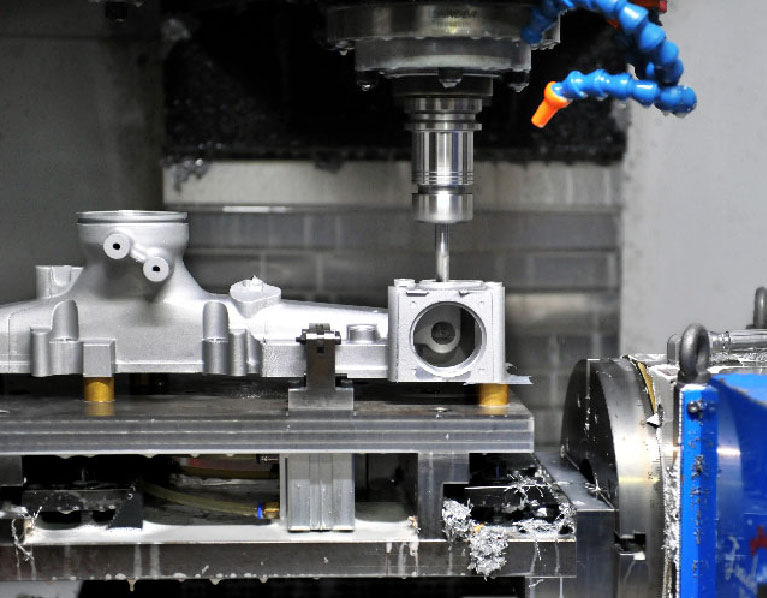

At Sunrise, we ensure high-speed production of a wide variety of die cast aluminum housing available in different sizes, shapes, and configurations. We offer visually appealing designs and parts with a long-serving life to suit each industry’s needs. The production process of die casting enclosures is executed utilizing cutting-edge technology and high-grade aluminum material. The procedure is strictly monitored by vigilant and expert quality controllers to ensure that all products’ dimensions are accurate and stable. We manufacture enclosures with full compliance in the set international standards.

Advanced Equipment For Die Cast Housing Components

Recent Die Cast Housing Projects

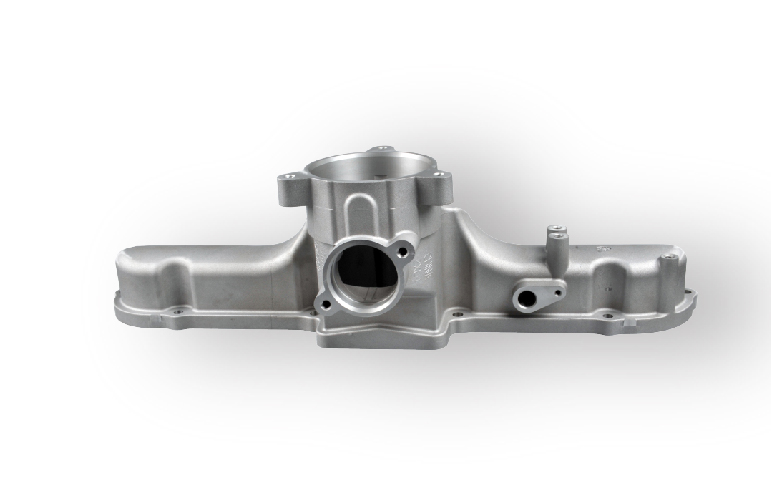

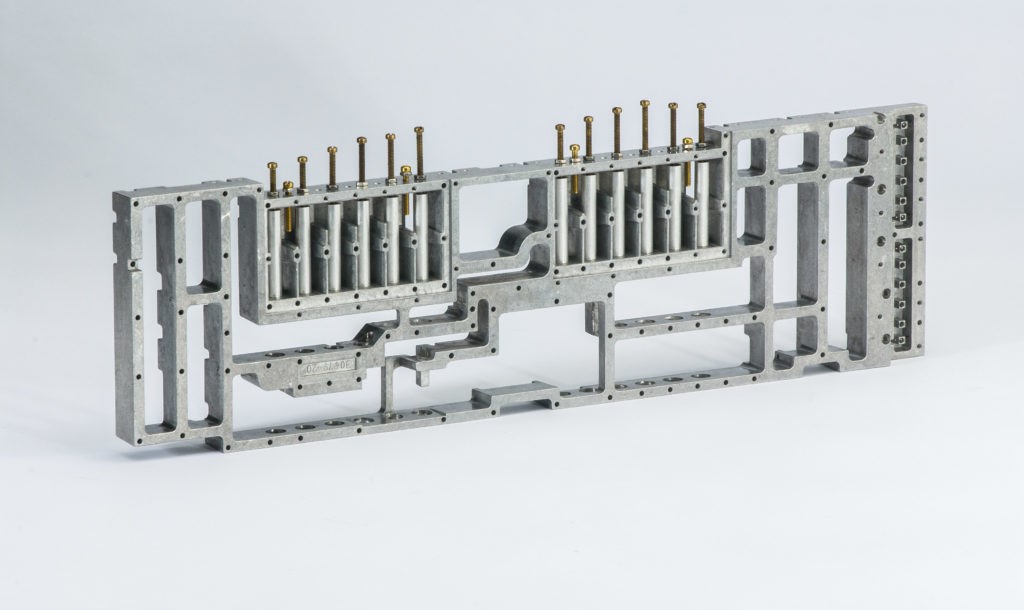

Part Name: Automotive Housing

Material: ADC12

Size: 147x129x131

Weight: 820g

Machine Tonnage: 400T

Surface Finish: Shot blasting

Production Process: Die Casting–Trimming–Deburring-Shot blasting

–CNC Machining–Leak test-Cleaning–Packaging

Applied Industry:AUTOMOTIVE

Part Name: Filter Housing

Material: ADC12

Size: 111x103x107mm

Weight: 520g

Machine Tonnage: 280T

Surface Finish: Chromating

Production Process: Die Casting–Trimming–Deburring

–Shot Blasting–CNC Machining–Leakage Test–Chromating

Applied Industry: AUTOMOTIVE

Part Name: Gear Valve Housing

Material: ADC12

Size: 81x80x79

Weight: 400g

Machine Tonnage: 400T

Surface Finish: E-coating

Production Process: Die Casting–Trimming–Deburring

–CNC Machining–E-Coating–Packaging

Applied Industry: GENERAL

DIE CAST HOUSING: THE ULTIMATE FAQ GUIDE

Our industry offers high quality and exceptionally perfect Die Cast Housing.

The products we offer are structured and created utilizing high-grade Aluminum alloys and cutting-edge modern-technology under the direction of our skilled professionals.

By far, most of Die Cast Housing items/parts are loved for easy installation, corrosion resistance, vigorous construction, reliability, and ideal finishing just as high durability.

The Aluminum Die Cast Housing has extended complex in the previous decade.

Our industry is one of the trusted manufacturers of a majority of Aluminum Die Casting parts to meet these varied demands and requirements

However, at each step of the Die Casting process, we give vital importance to quality and performance.

Our modern infrastructure and professionals support us in all our essential tasks.

- What is Die Cast Housing?

- What are the benefits of Die Cast Housing?

- What are the top fields in which Die Cast Housing plays an important part?

- Why are Aluminum alloys favored in Die Cast Housing?

- How is the Die Cast Housing cost-effective?

- How to stable the quality of Die Cast Housing products?

- What are the applications of Die Cast Housing?

- What is the advanced Die Cast Housing technology?

- What is the product design in regards to Die Cast Housing?

- What is the description of Aluminum Boxes, Aluminum Enclosures, and Aluminum Die Cast Housing?

- What is the importance of Aluminum in Die Cast Housing?

- What is the importance of thermal properties in regards to Die Cast Housing?

- What are the physical and mechanical properties of Aluminum alloys required by Die Cast Housing products?

- What are some of the crucial features Die Cast Housing products offer?

- How to choose the correct Die Cast Alloy for die casting housing?

What is Die Cast Housing?

The term Die Cast Housing refers to all the products made through the Die Casting process.

Our industry is a step Die Casting solution and offers a vast majority of Die Cast Housing products, including the custom product designs.

For example, Aluminum products like covers, shells, enclosures, etc.

Furthermore, the Die Cast Housing facilitates us in fields of telecommunication housing, automotive engine housing, automotive battery covers, etc.

Our industry offers unique Die Casting items in various determinations to meet the varied needs of enormous sizes of our customers.

What are the benefits of Die Cast Housing?

Because of the adaptability and advantages of the Die Cast Housing, the completing items can have numerous points of interest:

- Components are durable and dimensionally stable

- Effectively handling of complex shapes inside nearer tolerances

- The ability to combine many functions into one, complex-shaped parts

- A high rate of production

- Components, parts, and products can be produced with thinner walls

- Significantly more solid than elective plastic injection moldings

- Mass production enables the ability to thousands of identical castings

- Aluminum casting can be handily plated or gotten done with at least surface preparation

- Smoother surfaces than the vast majority of the casting structures, for example, sand or permanent mold

- External strings on parts can be included in the Die Cast Housing

- Include indispensable components, for example, bosses and studs bringing down the get-together expenses

- Aluminum castings offer fantastic corrosion resistance

What are the top fields in which Die Cast Housing plays an important part?

Die Cast Housing is a high-volume creation process.

It is to a limited extent since the Die Cast Housing is a productive, conservative procedure that offers a more extensive scope of parts in pretty much every technical field.

For electrical things, it can fill in as secure housing enclosures of PC and electronic parts, Aluminum, specifically, is the ideal decision for electronic hardware applications because of its exceptional EMI and ESD shielding without gaskets because of Aluminum’s electrical conductivity.

The top fields in which Die Cast Housing plays an important role are the following:

- High Volume Components

- General Engineering

- Automotive

- Hand & Power Tool Housing

- Pumps, Valves & Compressors

- Architectural

- Electronic Components

- Spare Parts

- Agriculture

- Medical

- Marine

Our industry has 10+ years of experience in casting, and our Die Castings are capable of extended service lifespan and are designed to complement the visual appeal of the surrounding housing for Die Casting products.

Furthermore, supported by a wide range of finishes and coatings to enhance human interaction with our products.

Why are Aluminum alloys favored in Die Cast Housing?

Aluminum alloys are the best as a result of their lightweight and the capacity to withstand the most noteworthy working temperatures.

A few of the most significant benefits of Aluminum in Die Cast Housing are that it can outstand corrosion resistance and have excellent thermal & electrical conductivity.

Furthermore, it offers an exceptional amount of finishing characteristics.

Some of the best Aluminum alloys for Die Cast Housing are A380 and ADC12.

How is the Die Cast Housing cost-effective?

Our engineers employ several techniques to maximize Die Cast Housing products’ quality and design while reducing costs.

Coming up next are the three principle costs related with Die Cast Housing:

- The Production: Depending on the part complexity, the Die Cast Housing can be intensely work concentrated and requires the dissolving of the Aluminum alloys.

- Secondary Operations: Machining, spraying, and finishing to achieve the specified part finish.

- Finishing: Any work of art, plating, silk screening, or engraving.

When planning another segment, think past necessary metal framing and consider die casting as the whole assembling process.

Moving things this way can radically diminish creation costs.

Furthermore, Die Cast Housing can be unbelievably cost-effective because one section can be intended to supplant different parts.

The following are some other factors that can affect the Die Cast Housing costs:

- Component complexity

- Die Casting Alloy

- Part tolerances specified

- Part finishing specified

Getting the engineer involved early in the process can significantly reduce the part costs.

Contingent upon the part multifaceted nature, the audit may incorporate a computerized liquid flow analysis to help guarantee the ideal part shape is optimized for the die casting process.

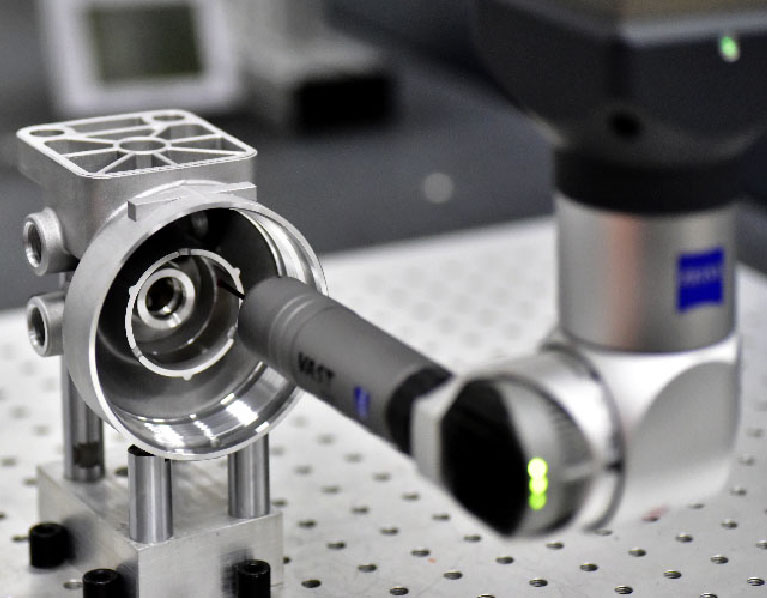

How to stable the quality of Die Cast Housing products?

There are five effective techniques to ensure the quality of Die Cast Housing products and which are following.

Furthermore, our industry makes every effort to output the best possible quality Aluminum products.

- Component Analysis: The material component check, which is essential to method the top-notch aluminum items, when we melt Aluminum.

- Dimension measurement and management: Checking and dealing with the items, the shape variety of mold, and the center are fundamental for the steady Die Cast Housing creation.

- Dimensional Check: Checking the product size and the unevenness under the mass-production is essential.

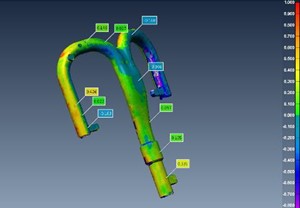

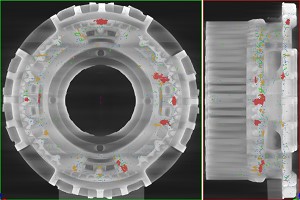

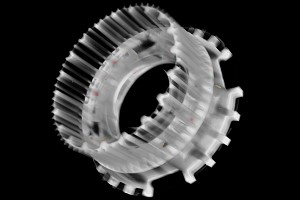

- X-Ray Test: Useful when checking the internal defects of the products by X-Ray.

- Micro CT scanning: It’s useful when measuring the internal defects of the products and can inspect the internal product without giving them any damages.

Looking to learn more know about Sunrise Metal’s Quality.

What are the applications of Die Cast Housing?

Die Casting Housing is most suitable and appropriate for casting medium-sized parts with sophisticated details.

It is a significant casting process used to manufacture in fields of;

- Medical

- Recreational Vehicles

- Traffic Lights

- Outdoor Lighting

- Firearms

- Industrial Equipment

- Telecommunications

- Automotive

- Marine

- General

Most Die Cast Housing is done from metals like Aluminum.

What is the advanced Die Cast Housing technology?

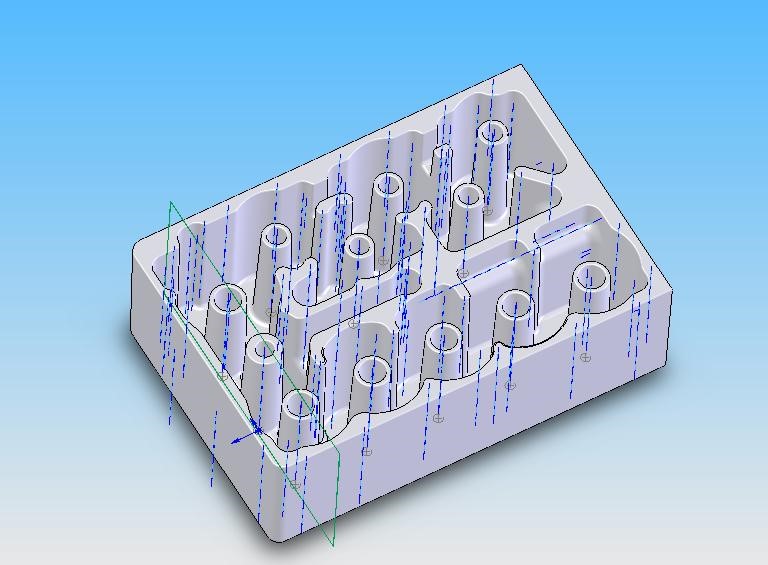

State-of-the-art machines and technology are used to provide process consistency, precision, and reduced labor.

Joining automated procedure observing and specialist staff of procedure professionals implies we can rapidly identify process issues and correct for out of control variables.

Using an authorized vacuum framework, we improve the surface finish and trustworthiness of our castings and molds, guaranteeing our customers get just the most excellent work.

Our industry implemented robotic work cells and process monitors to improve process flows and minimize waste.

These enable to produce consistently high-quality work that exceeds the expectations of the customers.

Also, stringent quality-control measures are implemented to detect and eliminate any product deficiencies.

What is the product design in regards to Die Cast Housing?

Die Cast design services are used to ensure the finished product is ideally suited for specific applications.

A fundamental component of the die casting design process is the advancement of modified prototypes that brings explicit one of a kind design and engineering necessities to life.

Prototype administrations improve the quality and productivity of items.

Extensive prototyping, prototyping parts, rapid prototyping, and prototyping forms are the most developed die casting innovations to actualize and make a finished result that surpasses client desires.

Product designs 2D & 3D are useful and considered essential in modern Die Cast Housing.

What is the description of Aluminum Boxes, Aluminum Enclosures, and Aluminum Die Cast Housing?

The terms “Aluminum enclosures” and “Aluminum Die Cast Housing” in some way, are the same.

These both are boxes die casted for several solid reasons.

Aluminum Die Cast Housing requires a minimum amount of labor in assembly than other processes.

Moreover, the cast aluminum enclosure parts are created at a rapid rate than other assembling forms.

Aluminum Die Cast Housing parts weight not as much as steel manufactured parts.

Aluminum Die Cast Housing is electrically conductive and further, when required, can be electrically grounded.

Aluminum box enclosures can be delivered with the mounting openings essential for introducing circuit sheets and covers to the enclosures to seal from dampness and harm to the parts amassed.

Aluminum enclosures function admirably with aluminum parts to expel and scatter heat from segments.

What is the importance of Aluminum in Die Cast Housing?

The Aluminum Die Cast Housing items are considered as electrically conductive and can be effectively electrically grounded.

In any case, what sensation Aluminum has become in the gear feature is no riddle.

Aluminum and its subordinates are, in effect, generally utilized in large organizations as well as in little scope use, for example, boxes and enclosures.

The following are some benefiting properties that make Aluminum a favorite and exceptional metal, especially when it comes to boxes and enclosures.

- Durability: Aluminum is the most durable, and its products are the most stable.

- Protects the stored material: Aluminum alloys have a very low reactivity when they come in contact with air.

- Lighter & Good texture: Aluminum is light and preferred mostly.

What is the importance of thermal properties in regards to Die Cast Housing?

Heating plates are generally found in the home and in research center gear that needs nonstop heating or wellspring of heat.

Besides, heat plates require the material which must have the thermal properties that are reasonable to assume the job of heating plates.

The most suitable and preferred material used for this purpose in Die Cast Housing is Aluminum and is also the most suitable.

However, industries using die casting in producing heating plates because, in this way, it can be more convenient and economical to use.

What are the physical and mechanical properties of Aluminum alloys required by Die Cast Housing products?

Aluminum is the world’s most copious material, and the adaptability of Aluminum makes it the most broadly utilized metal after steel.

This metal also contains the physical and mechanical properties required by the Die Cast Housing products.

Figure 13.1 (General properties of Aluminum alloys for Die Cast Housing)

Physical Properties – Aluminum

- Density: Aluminum is the element that considered the lightest metal accessible.

- Strength: Aluminum is appropriate to cold situations, and its tensile strength increments with diminishing temperature while holding its sturdiness.

- Corrosion Resistance: When exposed to oxygen or generally air, a layer of aluminum oxide forms on its surface. This layer has exceptionally brilliant corrosion resistance.

- Thermal Conductivity: Its x3 times greater than of steel, and this makes Aluminum an essential material for both cooling/heating applications.

- Electrical Conductivity: Aluminum has an electrical conductivity sufficiently high for use as an electrical conductor.

- Reflectivity: Aluminum is a magnificent reflector of radiation-rays and energy.

Mechanical Properties – Aluminum

- Tensile Strength: [46000-47000 PSI]

- Yield Strength: [23000-24000 PSI (0.2% Offset)]

- Shear Strength: [26000-27000 PSI]

- Elongation: [3.5 % inch per inch]

- Hardness: [80-85 BHN]

- Impact Strength: [3 Ft. Lb. (Charpy)]

- Youngs Modulus: [10.3 PSI x 10-6]

What are some of the crucial features Die Cast Housing products offer?

The following are some of the essential features we ensure the Die Cast Housing products carry:

- Dustproof and jet proof to environmental conditions

- Quick, easy, and safe installation

- The high-quality precision designs

- Enhanced lifespan

- Thermal-protected and voltage regulated drivers for specific products

- Low service and maintenance costs

- Maximized energy savings

- Vibration-proof

- Enhanced performance for project requirements

- Different color availability

- Effective thermal management

- Ergonomic design choice

- Sharp profile

How to choose the correct Die Cast Alloy for die casting housing?

Die Cast Housing alloy is chosen dependent on the environment; the part will work in the presentation necessities of the component.

Aluminum alloys are the best suited for die cast.

- A380: The most common and cost-effective aluminum alloy as well as offers the best combination of utility and cost.

Furthermore, selected for best corrosion resistance and pressure tightness.

- ADC12: It offers better die filling but with a moderate sacrifice in mechanical properties such as tightness.

- AlSi12: It’s selected for special applications where high strength, fluidity, and wear-resistance, as well as bearing properties, are required.

- AlSi9Cu: Offers further increase in ductility and typically used where performance requirements demand elongation properties.