One-stop Aluminum Die Casting Manufacturers in China

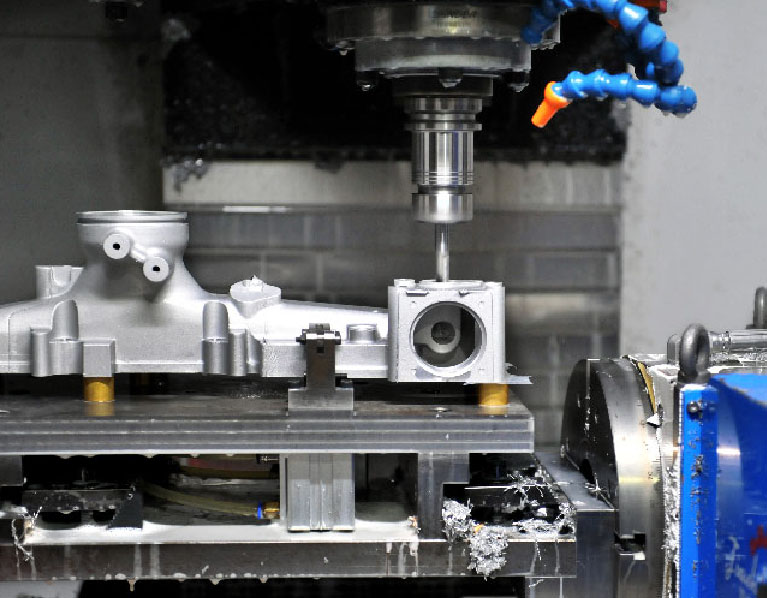

Sunrise Metals is the tier-one aluminum die-cast part manufacturer in China. With over 10 years of experience, professionals at Sunrise Metals are well-versed in the complete procedure and offer timely delivery of your aluminum die casting needs. Your required parts are produced at our dedicated die cast facilities with advanced equipment:

Aluminum 250T & 280T & 350T & 400T & 500T & 800T Die Cast set up.

Your required part is delivered with full-cycle production from design to machining. You can always benefit your industry with our premium aluminum die cast manufacturing services. Our skills, expertise, and experience have helped us achieve a reputation as a trusted aluminum die casting part supplier of China. You get the added advantage of achieving specialized products. Looking learn more about aluminum die casting.

Serving your precision aluminum die-cast needs with unmatched efficiency.

Faster Produciton with 1-stop Aluminum Die Cast Suppliers

Constant developments in technology, equipment, and design are made at Sunrise to get a competitive edge. Our teams are acting fast to keep you updated with industry trends. Our quick services will help you launch your product in reduced time as compared to other suppliers. The idea is to keep your product moving in line with the industry. Our fast production services will help you focus on design and revisions so you can get the best results possible.

Superior production. Careful inspections. Better marketing. At Sunrise we are one step ahead of the competition and we make sure you are too.

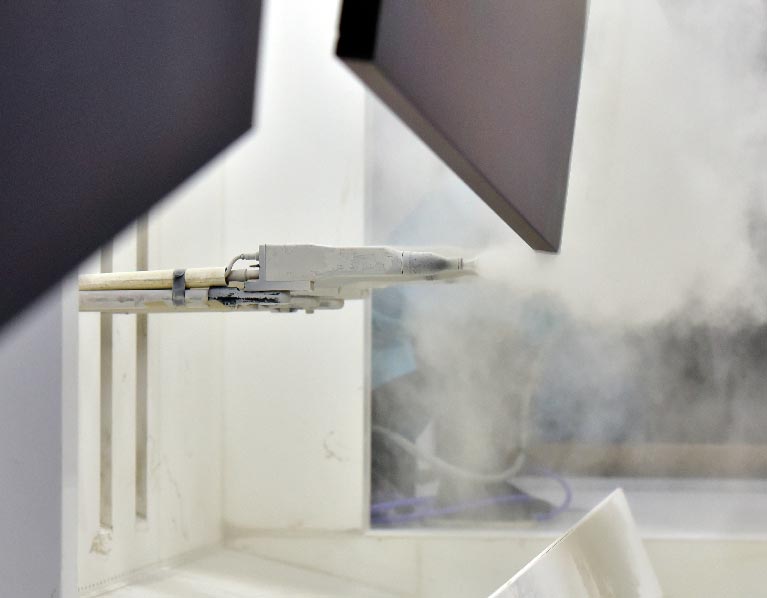

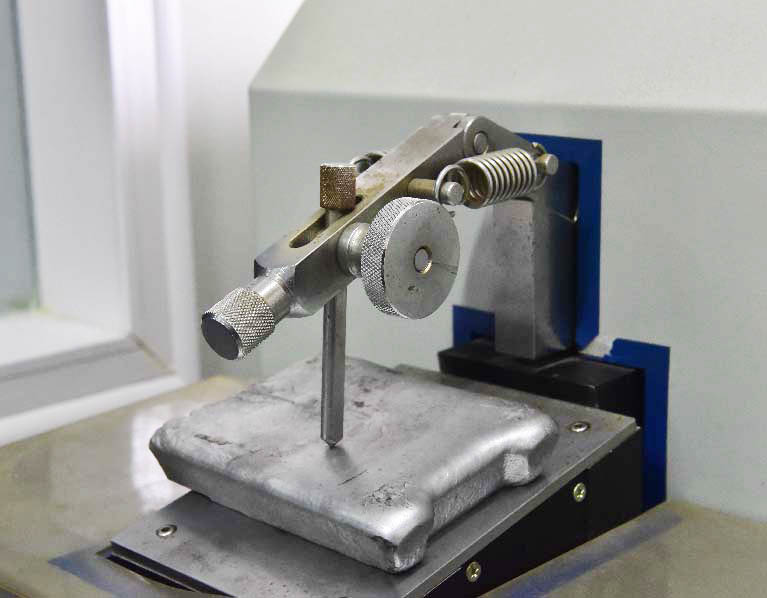

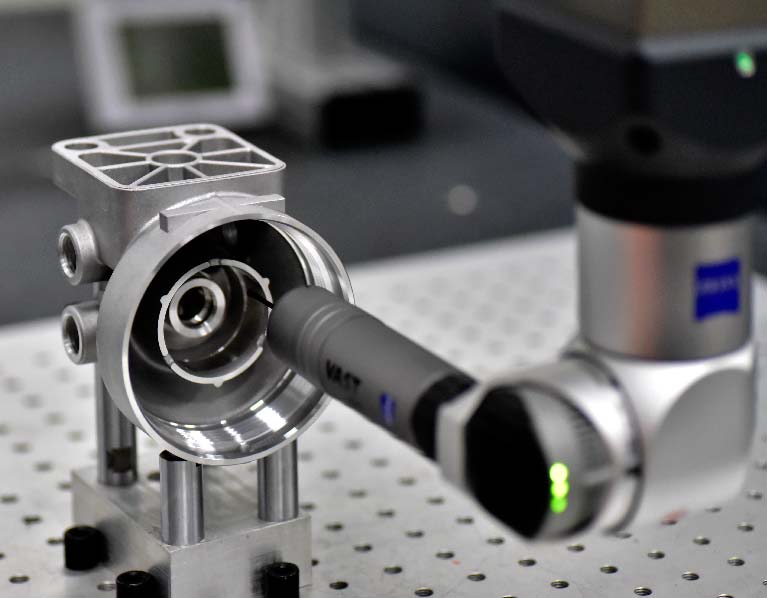

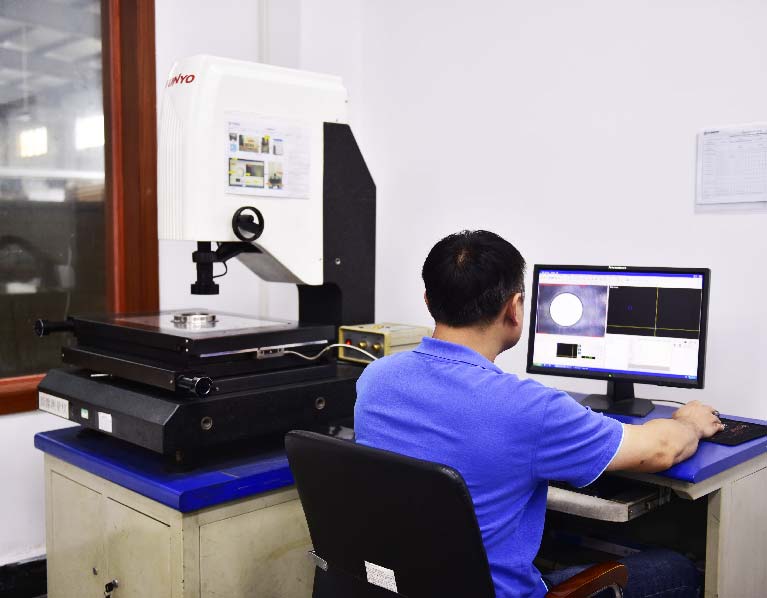

Advanced Measuring Equipment Ensure the Quality of Aluminum Die Casting Products

Precision Aluminum Die Cast Part Manufacturers For A Wide Range Of Industries: Ranging from miniatures to heavy die cast parts, Sunrise offers proficient die cast services for industries. With rich manufacturing experience, our production services accommodate your products no matter which industry it belongs to

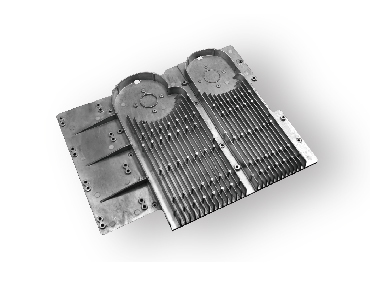

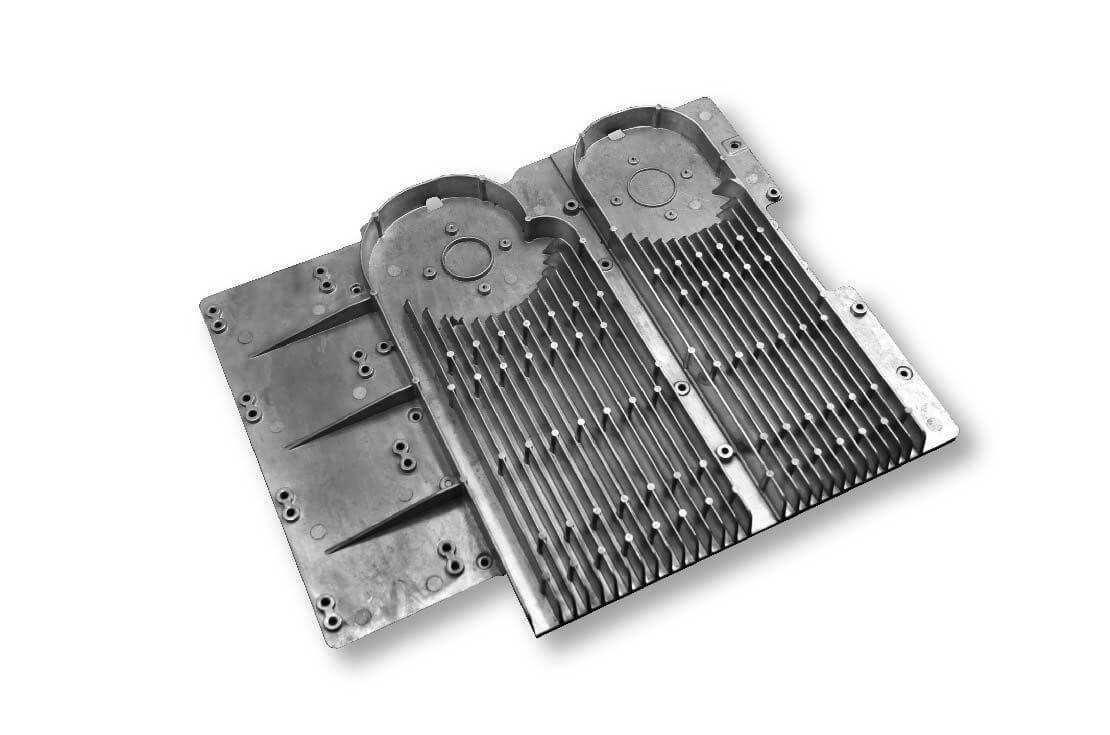

Part Name: POWER TOOL HOUSTING

Material: A380

Size: 300x150x80mm

Weight: 450g

Machine Tonnage: 400T

Surface Finish: Powder Coating

Production Process: Die Casting–Trimming–Deburring–Shot Blasting

–CNC Machining–Chromating–Coating–Printing–Screening–Packaging

Applied Industry: POWER TOOL

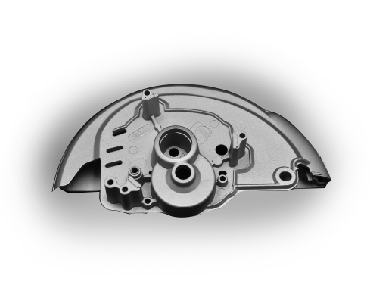

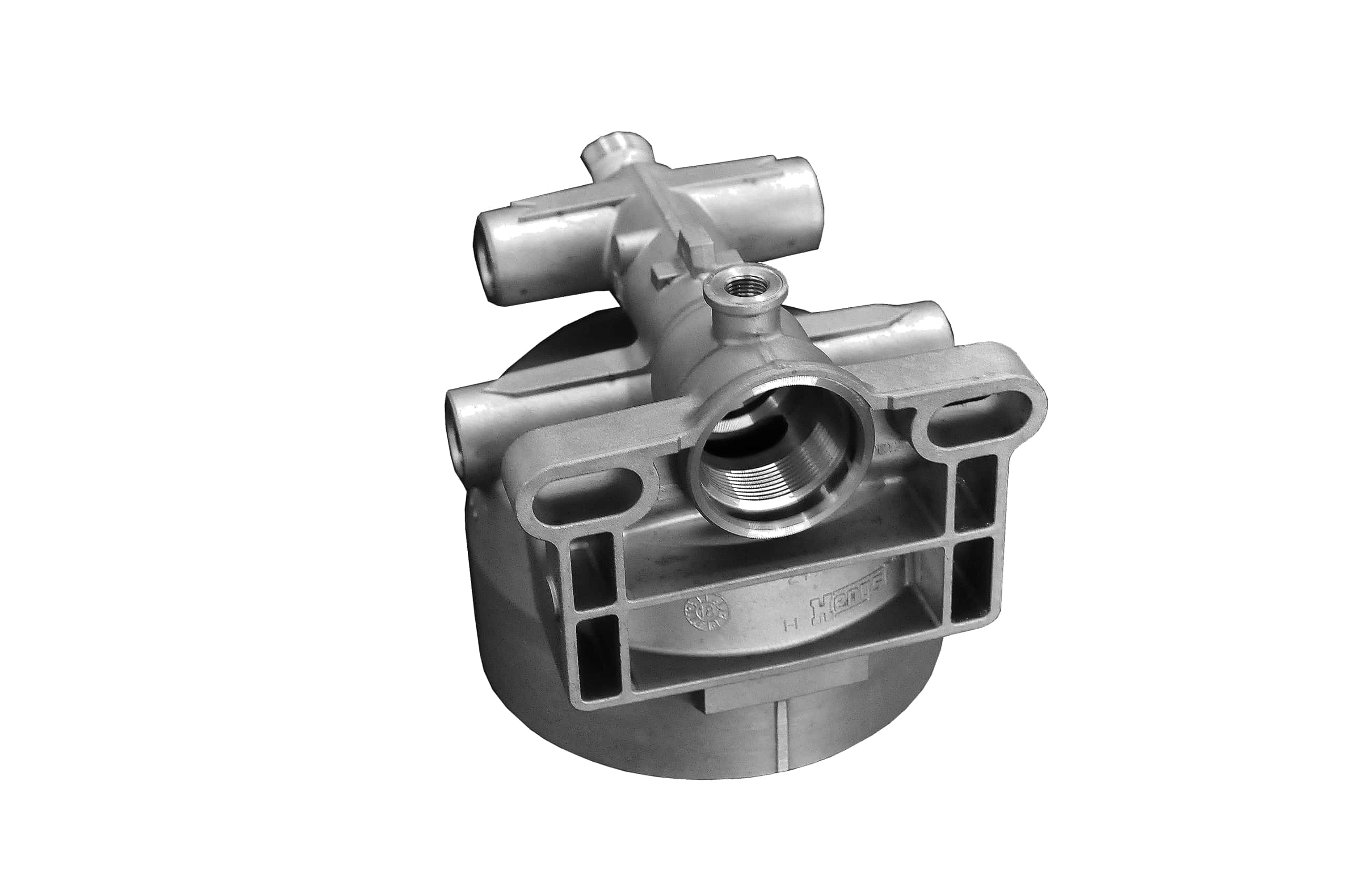

Part Name: GEAR VALVE

Material: ADC12

Size: 140x133x45mm

Weight: 230g

Machine Tonnage: 160T

Surface Finish: Powder Coating

Production Process: Die Casting–Trimming–Deburring–Shot Blasting

–CNC Machining–Chromating–Coating–Printing–Screening–Packaging

Applied Industry: CRUISE

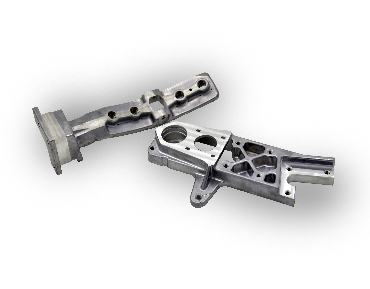

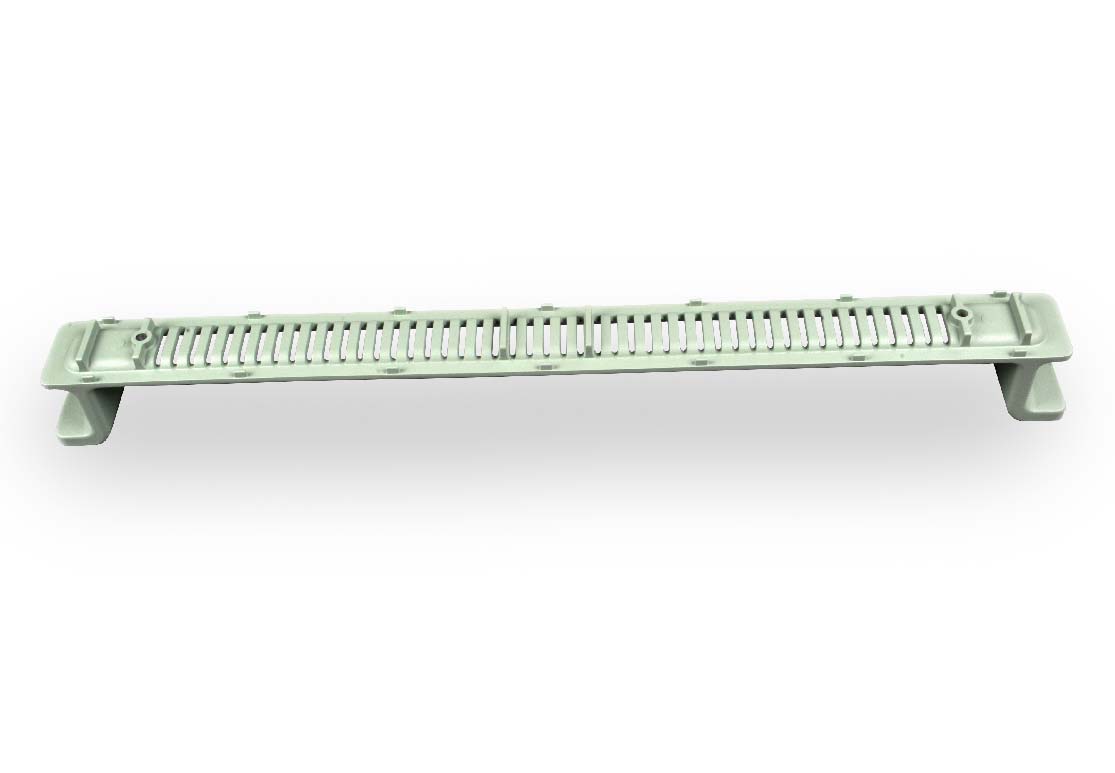

Part Name: Medical Casting BRACKET

Material: AlSi12

Size: 412x46x36 mm

Weight: 182g

Machine Tonnage: 400T

Surface Finish: Chromating

Production Process: Die Casting–Trimming–Deburring

–CNC Machining–Powder Coating–Screening–Packaging

Applied Industry: Medical

Part Name: Automotive Intake Tube

Material: ADC12

Size:451x138x125 mm

Weight: 1340g

Machine Tonnage: 800T

Surface Finish: Chromating

Production Process: Die Casting–Trimming–Deburring–Shoot Blasting

–Shoot Blasting–CNC Machining–Chromating

Applied Industry: AUTOMOTIVE

ALUMINUM DIE CASTING PARTS MANUFACTURER:

THE ULTIMATE FAQ GUIDE

Ordering aluminum die casting parts is not a child’s game. There are lots of things to take into consideration. Especially if you’re planning to purchase these from China manufacturers, you probably have a thousand questions.

In this guide, we’ll tell you everything there is about aluminum die casting parts and how to import them from China- the right way. So you don’t have to rely on a middle man or wander around.

All you have to do is read through the entire guide. So you can learn the ins and outs of this and make an order like a pro.

- What Is The Benefit Of Ordering Aluminum Die Casting Parts From China Manufacturers?

- Difference Between Buying Aluminum Die Casting Parts From Local Suppliers Vs. Direct Manufacturers In China?

- How To Get The Best Quality Aluminum Die Casting Parts From China?

- How To Find And Choose A Reliable Aluminum Die Casting Parts Manufacturer in China?

- Are You an ISO Certified Aluminum Die Casting Parts Manufacturer?

- What is The MOQ for Aluminum Die Casting Manufacturers in China?

- How Do I Know If The Aluminum Die Casting Parts Manufacturer is Perfect for My Projects?

- Things to Consider Before Purchasing Bulk Amount of Aluminum Die Casting Parts?

- How to Compare the Quality of Products Between Aluminum Die Casting Manufacturers In China?

- Can I Order Customized Die Casting Parts From Sunrise Metal?

- Can I Use My Existing Pattern for Ordering Aluminum Die Casting Parts from China?

- What Materials Do Manufacturers Use to Die Cast Aluminum?

- How Do I Know Which Manufacturing Process is Best for My Projects?

- How Can Sunrise Metal Help You as a Custom Designed Aluminum Die Casting Parts Manufacturer in China?

- What Aluminum Die Casting Parts Does Sunrise Metal Offer?

- What Is The Lead Time For Aluminum Die Casting Products If I Order From China Manufacturers?

- How Fast Can Sunrise Metal Manufacture and Deliver Aluminum Die Casting Parts?

- How Sunrise Metal Assure The Quality of Their Aluminum Die Casting Products?

- Why Aluminum Die Casting Parts Are So Useful For a Unique Design?

- What Industries Need Aluminum Die Casting Parts Manufacturer The Most?

- How Aluminum Die Casting Parts Are Used In The Automotive Industry?

- How Aluminum Die Casting Parts Are Used In The Marine Sector?

- How Aluminum Die Casting Parts Are Used In The Medical Sector?

- Why does the Telecommunication Industry Rely on Manufacturers in China for Their Aluminum Die Casting Parts?

What Is The Benefit Of Ordering Aluminum Die Casting Parts From China Manufacturers?

You already know you can get the most unique and quality products at a reasonable price from China. But there’s more to it. Businesses all around the globe depend on China manufacturers for a variety of reasons.

Especially if you’re a sourcing agent, buyer, or engineers from OEM and ODM companies who need custom-designed, higher-quality aluminum die casting parts, Chinese manufacturers can be a blessing. All you have to do is to find the right manufacturer and hand them your design and requirements. You’ll get exactly what you desire and more.

China is the leading manufacturer country for aluminum die casting parts. You won’t be able to find a manufacturer with similar quality and competitive prices as China, anywhere else in the world.

There’s a massive difference in being a businessman and being a manufacturer. Lots of businesses fail at the beginning of their business. Because they can’t maintain the quality of their products. Especially for critical or highly detailed products like aluminum die casting parts. It’s challenging to set up a manufacturing plant or even find a manufacturer locally for this.

This is where China manufacturers come in handy. You can get the best quality aluminum die casting parts at a cheap rate without going through all the hassles.

The first step of your business to ensure the supply of your products. The quality and cost of your goods can make or break your business. Ensure you have built the right pipeline by choosing the proper manufacturer.

Difference Between Buying Aluminum Die Casting Parts From Local Suppliers Vs. Direct Manufacturers In China?

Many buyers or sourcing agents take the shortcut and purchase bulk goods from their local supplier or vendor. They often think they have saved money and time doing so. Make sure you’re not one of them.

Why? Think this way, the products you’re purchasing from your local supplier have come from an importer. The importer purchased the products from a manufacturer in China. What if you’re the one ordering your aluminum die casting parts directly from China?

Exactly! You would’ve saved a lot of money. Even more, it’s often lower taxes to purchase goods from China than your local vendors. In this way, your goods’ cost remains minimal, and you have a higher profit margin.

The best part? You’ll be the one in control. When you depend on a local supplier, eventually you’ll hit a wall. And there’ll be nothing you can do about it. On the other hand, it gives you a lot of freedom when you’re in charge.

Especially for aluminum die casting parts, you’ll have your unique design and requirements. It would be best if you communicated with the manufacturers directly. So you and the manufacturer are on the same page and get the best results.

Wondering how? Well, let’s see:

You already know how you can save a lot of money by directly communicating with the manufacturer. But still, you might think purchasing from an importer or local vendor might be more convenient for you. Many people think this way because they assume it’s hard or more work to communicate with a manufacturer overseas.

But that’s not quite the case. Imagine you’ve placed an order to a supplier or importer; how much control do you have in your hand? None. Because you don’t know how the parts are being manufactured, what’s the production’s progress, and when exactly you’ll get the shipment.

Often, suppliers compromise the quality of the products when placing an order or choose the lengthy shipping method to make some extra profits. Well, this isn’t a worry when you’re placing the order.

Another major setback for relying on an importer is that people often realize that the final products at hand don’t match the actual design or requirements. The reason for this? It’s the lack of direct communications.

You don’t want someone else to communicate on behalf of you. When you’re the one that has better knowledge of your requirements and manufacturers are the one who knows how to make it so that you get what you expect.

Otherwise, you may fall into situations where you’ll lose a lot of money on defective products and also have to find another supplier and place another order for the same products. If you’re lucky and have time for a new order. Otherwise, you’ll be stuck with defective products and no time or budget to order new ones.

As a general rule of thumb, never rely on any middleman when you need something customized or very unique in design.

How To Get The Best Quality Aluminum Die Casting Parts From China?

China is the leading manufacturer of aluminum die casting parts. But you must ensure that you’re getting the top quality products. The process is not very difficult to follow. But you must follow these three crucial steps to ensure the highest quality:

Pre Production: This is the most crucial part. In this step, you’ll want to finalize the design and most importantly, the right manufacturer. Problematic design and the wrong manufacturer can be a nightmare if you fail to make the right decision in this stage.

If you’re concerned about choosing the right manufacturer, guess what? We’ll tell you every single detail on how you can select the proper manufacturer like a pro in the next question.

Imagine you’ve chosen your manufacturer, now what? Place the order, right? Wrong! In between finalizing the manufacturer and placing an order, you’ll have to do something else. And this is one of the most critical parts of ensuring your product quality.

That is evaluating your raw materials. If your raw materials are not up to the mark, your final products will never be as good as you expect. No matter how good your design is or how great the machines and molds are, if the raw materials are weak and inferior in quality, you’ll have defective products.

Ensure that you have chosen the right raw material according to your project

On Production: When you’ve finally placed an order, you shouldn’t sit idle. You’ll need to be in touch regularly with your manufacturer.

Making sure they are using the right materials, understanding your requirements, and strictly following the designs. And make sure they complete the production and deliver the goods before the due date.

Post-production: At this stage, your aluminum die casting parts are done manufacturing and ready to be shipped. But before they ship it out, it’s better that you run an inspection of the finished products.

You can hire an inspection agent or assess and examine the goods according to your given requirements. Although this step is not mandatory when working with a reliable company, they can do it for you.

How To Find And Choose A Reliable Aluminum Die Casting Parts Manufacturer in China?

First, find and qualify the manufacturers. You’ll find many aluminum die casting manufacturers by searching on Google or any other B2B platforms. You’ll need to qualify them according to your needs and make a shortlist.

Second, you need to verify them. A lot of the companies you’ll find with no physical address or phone numbers. Make sure they have a company address and valid phone number that you can dial and talk. Ensure that they’re an ISO certified manufacturer. Ask for a reference, pictures of their manufacturing plants, and see what works they’ve done before.

Third, communicate. Don’t sit and wait for emails; dial their number. Make sure the manufacturer understands your requirements and you learn their capabilities. Give them a clear understanding of what you need and ask for an estimated price.

Fourth, arrange a factory visit if you’re satisfied with the manufacturer and want to proceed with them. Don’t hesitate to ask for a factory visit.

If you cannot go by yourself, send one of your apprentices or colleagues to visit the factory on your behalf. If this isn’t possible either, you can hire many agencies to do this for you and report back to you.

Fifth, if you’re satisfied with the manufacturer and their production facilities and capabilities, order a small batch initially.

Finding the right manufacturer is one of the crucial factors for your business. If you fail to choose the best manufacturer for your industry, you will lose sales no matter how fast you try.

If your manufacturer makes the right quality parts but can not deliver in time, or if your supplier can give the parts at a low cost, but the quality is awful, your business will suffer.

While choosing, you need to be careful because you’re not only choosing an aluminum die casting parts manufacturer but also choosing a partner for your business.

Sunrise Metal is a leading aluminum die casting manufacturer in China determined to provide our customers’ best value. We serve companies globally with our state of the art product design and quality.

Are You an ISO Certified Aluminum Die Casting Parts Manufacturer?

Sunrise is an ISO 9001 and IATF 16949 certified manufacturer with over ten years of experience. Over the long course of experience, we’ve served more than 500 global customers. Our continually improving, inventing, implementing working process helped us acquire a lot of valuable patents.

What is The MOQ for Aluminum Die Casting Manufacturers in China?

The minimum order quantity varies from manufacturer to manufacturer. Generally, small companies can offer minimum MOQ but fail to deliver the optimum quality. On the other hand, big companies won’t accept smaller quantities or high mix.

Sunrise Metal can help you if you need a small amount or high mix of aluminum die casting parts. We welcome low to medium volume, as well as high mix aluminum die casting parts. So you can comfortably get your desired products at a better price and quality.

We help businesses worldwide by providing top-notch products at a low MOQ and high mix. Such companies like you can experiment and launch their new models and keep the cost at a minimum.

How Do I Know If The Aluminum Die Casting Parts Manufacturer is Perfect for My Projects?

You already know how you can choose a reliable manufacturer. But what if your company or relevant department has already selected a manufacturer? All you can do is make sure the manufacturer is perfect for your project. I’ll tell you how.

First and foremost, you’ll have to assess the experience of your manufacturer. If they have a decent amount of experience in aluminum die casting, you’re halfway through.

The next thing you’ll need to examine is their expertise and workforce to do the job. Because the expertise of their team can go a long way while manufacturing these complex materials. As well as capable engineers and a quality control team are one of the most essential assets for any manufacturer. Make sure they have both in place.

The perfect manufacturer should have the right machines and equipment to produce the die casting parts which match your requirements. They should be competent with manufacturing intricate designs that you provide.

Overall they should be able to continue manufacturing quality products that match your expectations. And most importantly, delivers on time.

Things to Consider Before Purchasing Bulk Amount of Aluminum Die Casting Parts?

If you’ve found the perfect manufacturer and ready to place an order, you’ve already done the hard work. Now some small issues need to be handled before you place your first order.

The first thing you’ll need to check with your country and custom’s law regarding aluminum die casting parts importing. Check if there are any particular recommendations or requirements your government has regarding this.

Second, you’ll want to make sure that your manufacturer understands your design and requirements by heart. They shouldn’t and mustn’t have any confusion or uncertainty about that. If they do, then it must be sorted out before the actual production begins.

Third, ensure your manufacturers are assuring the highest quality. Even the best companies can sometimes deliver the worst products. If you’re concerned about your products’ optimum quality, you’ll need to be more invested in this.

Fourth, Have a clear understanding of when you’re receiving the goods in your hand. Keep in mind that it’ll require a fair amount of time to ship the products in your destination in addition to the initial process and the actual production period.

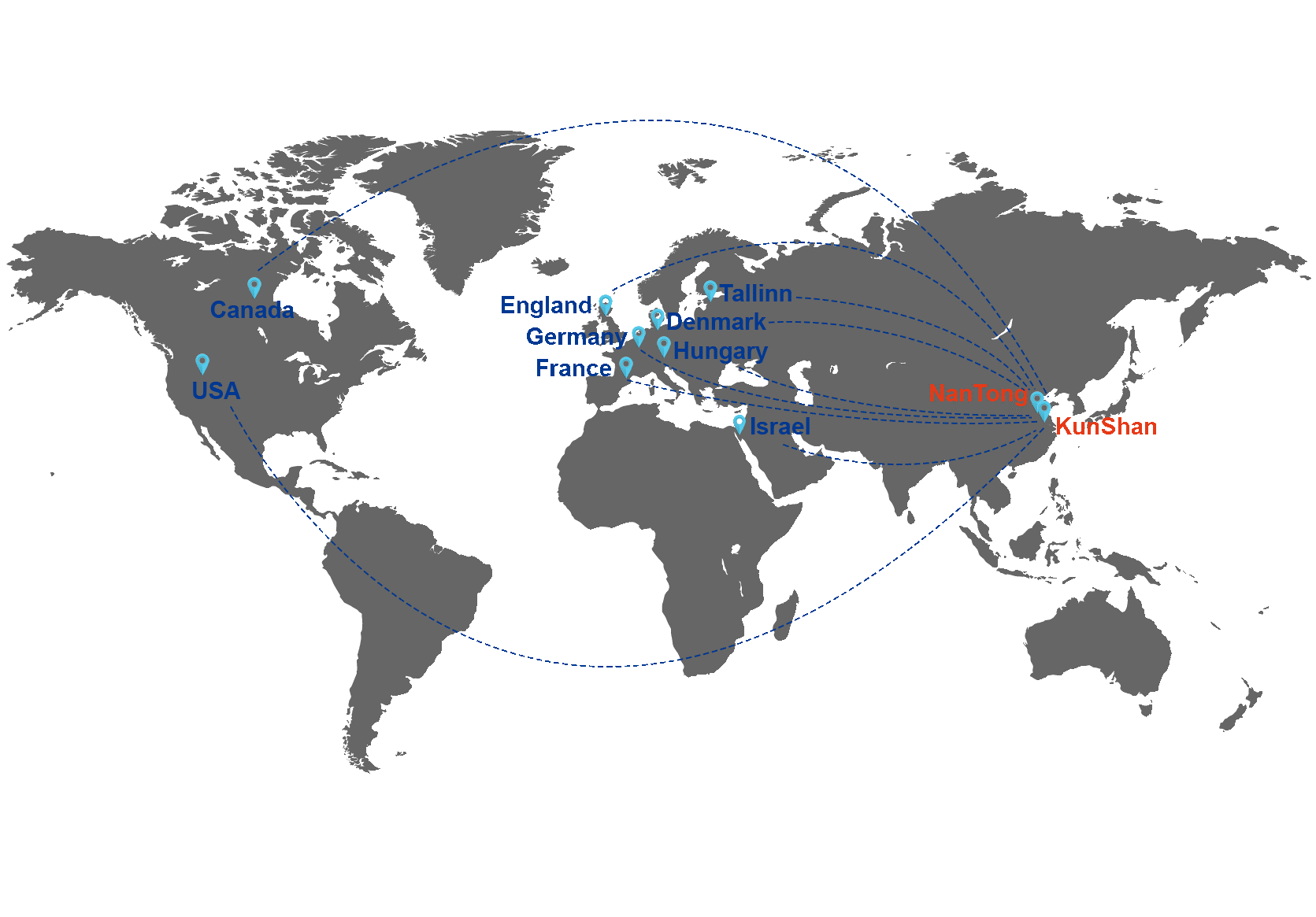

Fifth, before placing the order, see how easy the shipping process is for your manufacturers. This largely depends on the location of their factories. If your manufacturer’s factory location is near major seaports or airports, this can be a huge advantage and can save you a lot of money while shipping.

Last but not least, price. You and your manufacturer both have to come to an explicit payment agreement. Ensure that your contract protects both the parties and you’re paying the right price for your goods.

If you consider the above stated key points before placing your first order, you’ll have a smooth ride with any manufacturer you choose.

How to Compare the Quality of Products Between Aluminum Die Casting Manufacturers In China?

This is necessary when you have a shortlist of manufacturers. At that time, you want to be sure which one of them can provide the best quality aluminum die casting parts.

As I’ve said before, I’ll say again. The best way to evaluate the company and its quality, you’ll need a factory visit. By this, you can see how capable the companies are, what machines or equipment they use for manufacturing and meet the key people.

Another major advantage of visiting the factory is that you can see their past work sample, so you can better understand their production. You can also request to see what aluminum die casting parts they are manufacturing right then.

One other way you can use it is to see the past or current clients of the manufacturers. This should be available on their website, but you can always ask them directly about their past clients and any testimonials or reference they have from them. This will give you a clear idea of who they’ve been working with and how their customers think of them.

Also, don’t forget to ask about their quality control process and the certificates such as ISO or IATF.

Some of the happy clients of Sunrise Metal:

Can I Order Customized Die Casting Parts From Sunrise Metal?

Of course, you can. Sunrise Metal is the market leader in customized aluminum products manufacturing in China. We’ve worked with top companies in the world and made them happy with our products and services.

No matter how complex your design is, Sunrise Metal can make your design into a reality. We have served more than 500 global clients and manufactured more than die casting parts models.

When you’re working with Sunrise Metal, you’re in safe hands. Our engineers, production team and quality management team will ensure you get the exact product you desire.

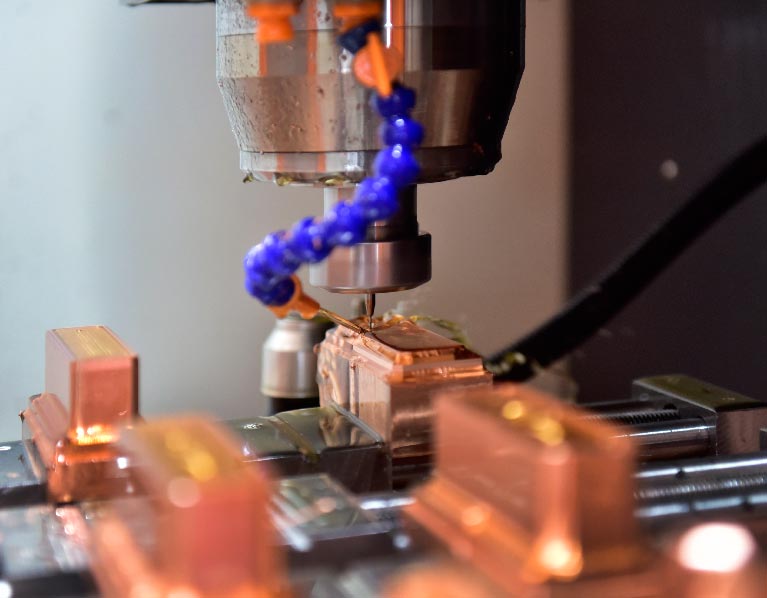

We use world-class equipment such as the Mazak 7-axis turning & milling Machine, Hass 5-axis CNC machine, among others, to produce the exact prototypes and designs as required.

Can I Use My Existing Pattern for Ordering Aluminum Die Casting Parts from China?

Yes! Like a custom design, you can give us your existing pattern and our experienced team of designers will create the perfect design from your pattern.

Our advanced pieces of machinery and team of experts will replicate your existing pattern in a highly detailed way. The best part is, if you want, you can make some adjustments and customizations too in the early stage.

We take on your existing pattern, and if you have any particular recommendation or customization, we implement those customizations in the final design. So you not only get your current design pattern but also have the chance to improve the existing pattern.

Our customers love our technology and creativity because we give our customers freedom and control over their products. We believe in customer satisfaction. We aim to provide the exact design with the highest quality. And that’s what differentiates us from other aluminum die cast manufacturers in China.

What Materials Do Manufacturers Use to Die Cast Aluminum?

The products they used for aluminum die casting varies from manufacturers to manufacturers. In general, manufacturers tend to use different kinds of aluminum, magnesium, zinc, and copper-based alloys.

At Sunrise Metal, we’re very picky about the alloys we use in our aluminum die casting process. So that we can produce the optimum product quality.

We use ADC12, A380, AlSi9Cu, AlSi10, AlSI12, and other types of aluminum alloys mostly. The alloy we choose depends on the types of aluminum die casting parts we’re producing. It also depends on the customer’s request.

We naturally use the best alloys for all of our manufacturing processes. But we also enable our customers to choose the alloy by themselves to suit their unique requirements. This is another reason our customers love to work with us.

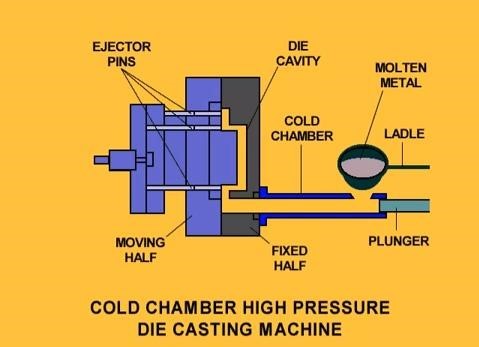

How Do I Know Which Manufacturing Process is Best for My Projects?

For aluminum die casting parts, cold chamber die casting is more suitable. Because aluminum and magnesium alloys have a high melting point, it’s more logical to use a cold chamber to cast them.

On the other hand, hot chamber die casting is used for alloys with a low melting point, such as zinc and copper. Because of their low melting point, they can be died using a hot chamber.

When you need aluminum die casting parts, your manufacturer must use cold chambers to die cast the aluminum alloys.

How Can Sunrise Metal Help You as a Custom Designed Aluminum Die Casting Parts Manufacturer in China?

When you have Sunrise Metal as your manufacturer, you’ll get what you want and more. Sunrise Metal is determined to provide you the most refined custom-designed aluminum die casting parts at the best price.

One thing that we can never compromise is quality. And one thing we never miss is our due date. No matter what parts we are manufacturing for whichever industry, quality is our priority.

With Sunrise Metal, you get what you want, and before the due time. Compared to other manufacturers, our lead time is almost half, making us a favorite for global buyers who have limited time in hand.

Our state of the art value engineering allows us to produce the parts at a minimal cost and minimize the wastage. Which helps our customers to get the best products at a great price. We welcome sourcing agents, buyers and OEM/ODM companies that require a low to medium volume or high mix. For some parts, we can take orders as low as one unit.

One of the reasons you’ll love to work with us is that we enable our customers to have full control. From the design to raw materials, our customers can choose exactly how and what final goods they want to receive.

Our production plant is situated in a prime location where we have the most advanced airports and seaports nearby. As well as the world’s busiest high-speed train network. This enables us to get the best raw materials and shipping the final products to our customers fast.

Our one-stop solution helps buyers save a lot of time and effort. Because you’ll get rapid prototyping, tooling, die casting, machining, assembling, surface treatments all in one place. So you don’t have to jump from one manufacturer to another for various needs. You’ll get all in one. Which saves you a lot of money and time.

If you’re from automotive, marine, telecommunication, instrumentations, or even general industry, working with Sunrise Metal will make your life a lot easier.

We not only focus on what our customers need, but we also focus highly on what our customers want. Because we don’t take our customers as another lead, we believe our customers are our business partners who allow us to continue the great work.

What Aluminum Die Casting Parts Does Sunrise Metal Offer?

Sunrise metal is a leading manufacturer in the world when it comes to aluminum die casting parts. We have served over 200 global clients with 2500+ die casting parts and counting. We can manufacture any aluminum die casting parts that you desire.

Here are some of the industries and sectors that we’ve mastered manufacturing:

- Automotive IndustryEngine

Body and Chassis Components

Safety parts - Marine & Ship EquipmentsMaritime Satellite Communication

GPS Positioning System

Hunting Underwater System - TelecommunicationRadar & Frequency Control System

Antenna

Transmitter

- Instrumentations and General IndustryUltrasonic Scanner

Flow Control System

Textile Industry

And a lot more. Feel free to reach out to us and see if we can help you and how.

What Is The Lead Time For Aluminum Die Casting Products If I Order From China Manufacturers?

The lead time is very different from one manufacturer to another. Because everyone has their own efficiency level and can’t complete the production in the same time period. On top of that, other factors affect the overall lead time as well.

Mostly the lead time depends on the efficiency of the manufacturer. They should be highly efficient in sourcing raw materials and starting production.

The workforce and equipment capacity is a significant factor, as well. If the manufacturer has a team of expert and fast workers and has fast machines, preferably multiple in numbers, they can produce the parts faster than others.

On the other hand, if the manufacturer cannot organize a fast working team and fine machines, they will need more time to produce the parts.

The factory location also makes a huge difference. If the production plant is in a prime location where raw materials are easy to access, they can start the process faster than others.

On top of that, a great location will have better internal transportation and airports, seaports nearby, which makes them able to quickly and efficiently ship out the final products to their customers.

Overall, if the company is built upon a strong and effective foundation with strong leadership, they will quickly deliver the products. The lead time of a company can say a lot about their leadership and ability.

How Fast Can Sunrise Metal Manufacture and Deliver Aluminum Die Casting Parts?

On top of that, our factory location enables us to get raw material fast. Nearby multiple airports and seaports allow us to ship out the final goods to our customers more quickly than anyone else.

For a volume of fewer than 200 pieces, we can deliver the final products in 1-2 weeks. For a larger volume it can take 2-4 weeks approx.

Before we make the final agreement, we will assure you the duration. And Sunrise Metal never misses their due date; this is something you can be assured of.

How Sunrise Metal Assure The Quality of Their Aluminum Die Casting Products?

Sunrise Metal is a world-renowned name when it comes to aluminum die casting parts manufacturing. Our experienced team of engineers and quality control allows us to produce the best quality products.

Our state of the art machines allows us to manufacture flawless parts and with a value engineering formula. Then ensure the highest quality of the products with the lowest cost for our customers.

Our quality control team will ensure that the parts are exactly according to your requirements in design and quality. We never compromise the quality of our products because that goes against our core value.

We use world-class machinery and premium quality alloys to make the product superior in quality. Manufacturing defective goods is not an option for us.

We ensure the product according to the two widely known QC standards;

ISO 9001:2015

IATF 16949:2016

These enable us to provide the highest standard service for our customers. From the design stage to the finished product, our expert workforce will offer you an unforgettable experience. We’ll let you be in control of your design while securing the optimum quality of your desired product.

Why Aluminum Die Casting Parts Are So Useful For a Unique Design?

Aluminum die casting parts are widely popular because of their customizable ability and ease of making the complex design reality. We could manufacture very complex parts that would be very hard or near impossible to manufacture the die casting process.

The aluminum die casting process enables us to manufacture a bulk amount of parts with great strength and durability. Although the parts are great in strength, their weight is relatively low, making it the best choice for aerospace, marine or many other industries.

The accuracy and stability play a significant part in becoming so widely used in the telecommunication and medical industry. When defective products aren’t an option for you, you’ll want to go with aluminum die casting parts. Aluminum die casting parts are corrosion resistant, which makes it a better alternative for more prolonged use.

Die casting parts are made with thinner walls and higher durability and strength than other casting methods like plastic injection. The quality of aluminum die casting parts are far more superior than other alloys or casting methods. This is why industries that require precise design and the highest accuracy tend to rely on this method.

What Industries Need Aluminum Die Casting Parts Manufacturer The Most?

Companies from various industries from all around the world are leaning towards aluminum die casting parts for their needs. Here are some of the few industries that we served with our world-class parts:

- Medical & Health Care

- Automotive Engine & Electronics

- Communications & Networking

- Smart Metering

- Marine Electronics

- Industrial & Commercial

- Aerospace Electronics

- LED Lighting

These are only a few of the industries that are very much dependent on aluminum die casting parts. Because of these parts’ quality, strength, and OEM and ODM companies, sourcing agents and buyers rely on this process for their unique and customized designs.

All the industries that require unique products with their design are now using this method for their requirements. We’ve had many clients who had used other methods before and had to shift to the aluminum die casting process for better accuracy and quality.

How Aluminum Die Casting Parts Are Used In The Automotive Industry?

If you’re from the automotive industry, you already know how important it is to get the accurate products of your required design. The automotive industry is one of the first industries to use aluminum die casting parts worldwide.

Automotive manufacturers tend to rely on this process to a great extent. Starting from the engine to safety parts, they use aluminum die casting parts for a wide range of applications within a vehicle. Some are:

- Engine

- Body

- Chassis component

- Safety parts

As you can see from the above, most of the vehicle parts are actually made from this process. The reason being is automotive manufacturers launch new models of cars very often. And when they do, they require a uniquely designed engine, body, safety parts, and other parts.

And this is when aluminum die casting parts to come in handy. Companies have minimal options when it comes to those parts because they can’t rely on processes that can not match their requirements both in design and quality.

With the aluminum die casting process, we can provide them with the highest quality parts for their automotive companies. And the best thing is that they get the exact design and requirements as they require. The cost is also less and mass production is faster than others.

For these above reasons, the automotive industry is pretty much dependent on aluminum die casting parts.

How Aluminum Die Casting Parts Are Used In The Marine Sector?

Aluminum die casting parts are widely used in the marine sector. Especially in underwater submarines, hunting underwater systems and ship equipment. These parts are used for maritime satellite communication, GPS positioning, and other equipment that require higher accuracy and unique requirements.

For the majority of communications and positioning tools, aluminum die casting parts are favorite. Because the accuracy and custom design of the products allow the marine industry to have precisely what they require.

One of the reasons why these are used in the marine sector is their corrosion resistance ability. Other metals can be extremely vulnerable to corrosion, especially on the water.

Other than that, their long lifespan, easy cleanability, low cost compared to other materials, lightweight but superior strength makes them the favorite for the marine industry.

How Aluminum Die Casting Parts Are Used In The Medical Sector?

Medical equipment parts are different in a sense for other industries. And that is when it comes to medical equipment, lives can depend on it. So there are no shortcuts or adjustments.

They have to ensure the exact and precise product with ultimate quality. And for this reason, Sunrise Metal, along with other quality manufacturers, have to be extra careful when manufacturing these parts.

Most of the medical equipment designs are incredibly complicated and require 100% accuracy. Any less than that and the goods are not workable. This is why aluminum die casting parts are perfect for the medical sector.

This process can make complex equipment like operating robots, dialysis equipment. And other equipment like monitors, DNA sequencing equipment also requires precise design accuracy and quality.

Because most of the equipment interacts with the patients, some internally, you’ll have to 100% sure of the quality of the parts and the material it’s created from. And aluminum die casting parts are perfect in all senses.

Many surgical equipment and tools interact with bodily fluids and tissues. Doctors and medical professionals need something stainless, corrosion-resistant, highest quality material, and increased durability.

Aluminum die casting parts can deliver all these with a cost-effective process. For those reasons, almost all medical sectors, medical professionals, and doctors recommend aluminum die casting parts for most of the equipment and tools.

Why does the Telecommunication Industry Rely on Manufacturers in China for Their Aluminum Die Casting Parts?

Aluminum die casting parts are widely popular in the telecommunication industry. Here are some of the examples:

- Radar

- Frequency control system

- Antenna

- Transmitter

Like any other industry, the telecommunication industry also requires quality products with the highest durability. But the most crucial factor for them is the cost-effectiveness of aluminum die casting parts.

Because it can be produced faster and at a low cost, the telecommunication industry loves to use those materials for various requirements and equipment.

A lot of the equipment they require is used outdoors. So the corrosion-resistant ability of the parts also plays a major role. And the accuracy of the parts allows them to have precise parts when it comes to the frequency control system and transmitter.

Conclusion:

Now it’s your time. We’ve outlined all the basic and advanced questions about aluminum die casting parts and how to purchase them from China. How helpful was this guide for you?

And most importantly, is there still any question that you didn’t find here? Don’t hesitate to let us know if we’ve missed something. We’d love to help you with that and also add that question to this FAQ guide.

About Sunrise Metal:

Are you looking for a reliable aluminum die casting parts manufacturer from China? Or are you currently purchasing from a mediator and wanting to order directly from manufacturers?

You’re in the right place! We’re the leading aluminum die casting parts manufacturer in China with 10+ more years of experience and multiple production plants.

No matter how complex your design and requirements are, Sunrise metal can help you with your project. We don’t take shortcuts; we believe in quality.

Let’s have a chat and see if we can work together to grow your business together. Feel free to reach out to us here, or send a direct email to sales@sunrise-metal.com.