WHY SUNRISE METAL

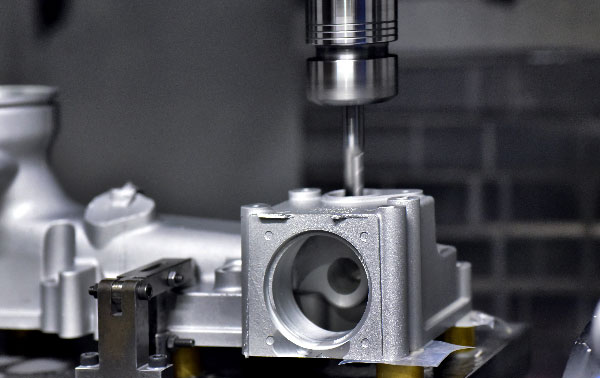

Sunrise Metal is a reliable, quick-turn, aluminum machining service provider in China. Our advanced CNC machinery guarantees premium aluminum machined parts to our customers. The precision machining centers allow us to provide your aluminum parts with tight tolerances and meet different projects’ demands.

Our CNC machining capabilities include:

- CNC milling machining

- CNC drilling & tapping

- CNC turning & boring

Our in-house machining facility and various finishing services can offer your cost-effective solutions for short-run production. Contact us for requesting all your CNC machining needs.

ONE STOP CAPABILITY

We offer a wide range of services other than just die casting. Our one-stop service Starts from rapid prototyping to high-quality surface finishings. We help you get the final product with ease and here in one place.

- Aluminum Alloy

- High Precision Al CNC Machining

- Aluminum Surface Finishing

Aluminum Alloy

The use of aluminum alloys in CNC machining is favored due to their lightweight nature and exceptional dimensional stability, making them well-suited for the manufacture of complex parts. With good mechanical properties and being readily available, offer a highly attractive option for CNC machining applications.

Our alloys include:

Aluminum Grade 5xxx Series Alloys

Aluminum Grade 6xxx Series Alloys

Aluminum Grade 7xxx Series Alloys

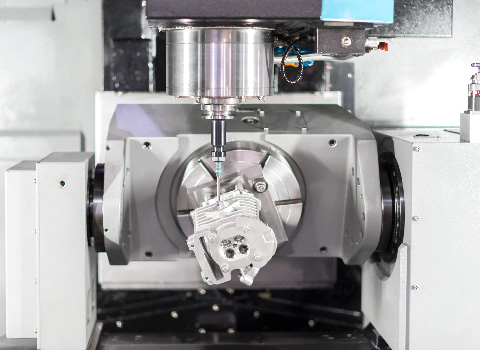

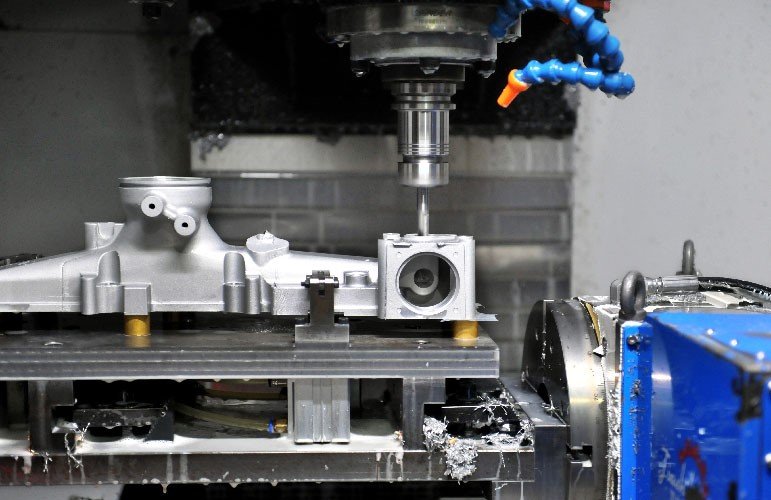

High Precision Al CNC Machining

We offer comprehensive CNC machining services, utilizing state-of-the-art machining centers that are equipped with all the necessary tools for aluminum part machining. Our advanced equipment and processes enable us to maintain high tolerances and achieve exceptional precision, such as +/-0.0015 (JIS B6336) with our Makino F5 machine.

Additionally, our CNC milling shop features precise CNC machines, such as the Mazak 7 axis and Haas 5 axis, with precision tolerances up to 0.005mm. This allows us to accommodate a wide range of aluminum machining projects with varying precision requirements.

Our aluminum machining services encompass:

- Aluminum Extrusion

- Aluminum Prototypes

- Machined aluminum die-cast parts

which offer a full spectrum of capabilities to meet your specific needs.

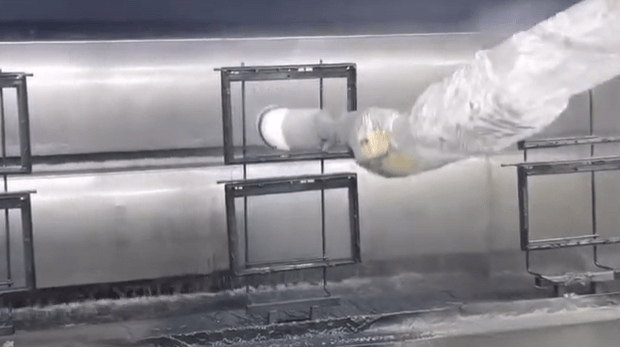

Aluminum Surface Finishing

We offer a 1-stop solution service for your CNC machining parts. It surely includes cleaning, anodizing, chrome plating, powder coating, wet painting, E-coat paint, silk printing, laser etching, etc.

Anodizing provides a clean, uniform, corrosion-resistant coat normally for machined products.

Powder coating & liquid painting have a corrosion-resistant layer and meet different appearance requirements

Silk screening, pad screening, and laser carving provide an ID or logo recognition.

OUR EQUIPMENT

Comprehensive machines and equipment allow us to provide a customized solution to each customer’s needs. We will continue to invest in superior equipment with technological innovation.

- Advanced Precision Machining Equipment

- Quality Measuring Equipment

| No. | Name | Stroke | Q’ty |

| 1 | Makino 3-axis CNC machine with Lehmann Fourth axis | 900*500*450MM | 1 |

| 2 | Makino 3-axis CNC machine | 900*500*450MM | 1 |

| 3 | Mazak 7-axis turning&milling machine | φ658*1011MM | 1 |

| 4 | Mazak/Hass 5-axis CNC machine | φ850/φ600 | 4 |

| 5 | 3-axis CNC machine | 2000*1500MM | 1 |

| 6 | 3-axis CNC machine | 1000*600*600MM | 20 |

| 7 | 4-axis CNC machine | φ250*800MM | 8 |

| 8 | CNC lathes | φ320*800/φ610*1000MM | 2 |

| 9 | Sodick wire cutting machine | 400*400*200MM | 3 |

| 10 | EDM machine | 500*400*200MM | 2 |

| 11 | Surface grinder | 600*300*200MM | 1 |

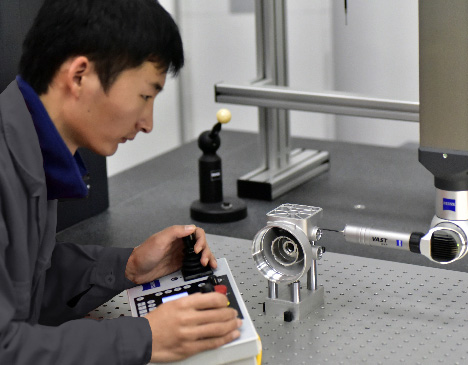

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

ENGINEERING SUPPORT

Sunrise’s engineering team uses computer-aided engineering (CAE) and with their rich technical experience, they can optimize the design for rapid prototypes, and machined parts. Moreover, our engineers are professional in the application of CAE including:

- Pro/Engineer and Pro/Manufacture to ensure feasibility for your products’ design, and manufacturing.

- Proficient at working with CAD/CAM files from the virtual system.

- Valued engineering solutions to help reduce costs throughout the manufacturing process.

OUR QUALITY

OUR LABORATORY

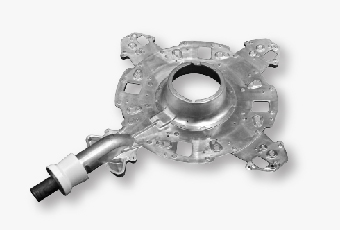

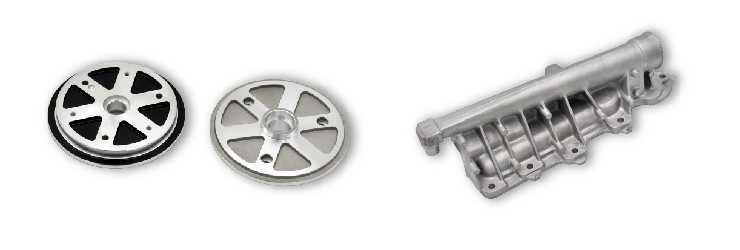

PROJECT GALLEY

- Filters from Automotive Industry

- Lawnmower’s part from General Industry

- Components for Marine Electronic

- Applied in Medical Equipment Industry

- Lawnmower’s part from General Industry

LISTEN TO THE VOICES OF OUR CLIENTS

I am very appreciated. The BK products that you folks support are on an upswing, so hopefully, 2020 will be prosperous for both companies. I also want to thank you for your support in cost reductions and pulling in deliveries. Much appreciated.

Sunrise never let me down, whatever the new projects or current ongoing parts. They do have rich experience and this great help. I like their perfect DFM, really fast, and on-time delivery.

Thank you, the quality is very well. I wish next year will be successful so that we can do more business with you.

PROUD SUPPLIER OF

ALUMINUM MACHINING SERVICE:

THE ULTIMATE FAQ GUIDE

Aluminum machining service is getting widely popular nowadays. Because of aluminum’s high machinability and low-cost process, you can now have the best quality machined product at a lower price!

Although, finding the right manufacturer, communicating with them, and finally ordering your desired product is not a child’s game.

Many small variables can make a huge difference in your product’s design and quality. Before ordering, you need to know all the ins and outs of it.

This article aims to let you know what’s the most important things to know and consider before ordering an aluminum machining service from China.

- What is CNC Aluminum Machining Service?

- Why You Should Choose Aluminum Machining Service?

- How to Choose a Reliable Aluminum Machining Service Provider in China?

- How Does Sunrise Metal Ensure Optimum Quality when it comes to Aluminum Machining Service?

- What is the Cost of a Custom CNC Aluminum Machining Service?

- What Process Do They Use in Aluminum Machining Service?

- What is The Minimum Wall Thickness in Aluminum Machining Service?

- What is the Difference Between Steel Machining Service vs. Aluminum Machining Service?

- What is the MOQ for Aluminum Machining Service?

- What Tools Does Sunrise Metal Use in Aluminum Machining Service?

- What are the Benefits of Aluminum Machining Service?

- Why Should I Choose Sunrise Metal for Aluminum Machining Service?

- What is the Standard Lead Time for Aluminum Machining Service?

- What are Some Product Examples of Aluminum Machining Services?

- Why Do Manufacturers Use Lubrication in Aluminum Machining Services?

- Why Sunrise Metal Uses High-Speed Machining for Aluminum Machining Service?

- How to Increase the Efficiency in Aluminum Machining Service?

- What Surface Finish Can Sunrise Metal Offer in its Aluminum Machining Service?

- What Quality Management System Does Sunrise Metal Have?

What is CNC Aluminum Machining Service?

CNC or Computer Numerical Control machines can manage tools around a different number of axes. With these machines, manufacturers can make a substantial part with the help of a computer design file.

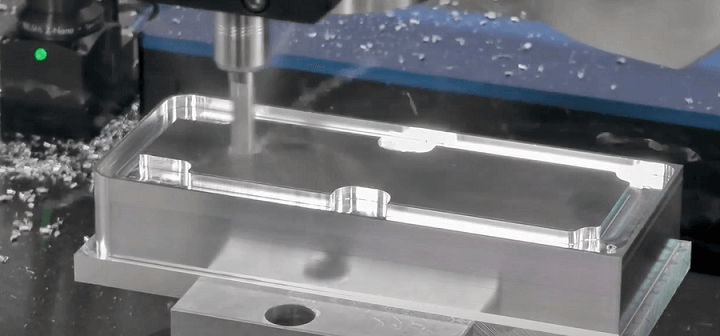

CNC machining is a subtractive process, which extracts material from an aluminum piece and makes a shape out of it. These machines are dependent on the computer design and do exactly what they’re instructed to. CNC machines are used in both prototyping and final production.

The primary benefit of CNC machining is the accuracy and speed it has to offer. In the early stage of this machine, it used to rely on machinists to provide the instructions manually.

But as technology grew, now it’s entirely dependent on computers and computer-based designs. Engineers use programs like CAM or CAD to provide the exact design and instructions to the machine. And the rest is done.

There are many different ways to remove the material from stock, using CNC machines. Such as drilling, lathes, milling, turning, tapping, grinding, etc. The milling machine is similar to the drill method and the most popular among others.

Sunrise Metal has the capability to implement methods that are compatible with your project.

Why You Should Choose Aluminum Machining Service?

If you’re looking for custom-made or designed products, an aluminum machining service is perfect. The high machinability of aluminum makes it easier and less costly compared to other materials.

Aluminum offers higher strength and corrosion resistance, making it the most popular choice for machining among buyers in OEM/ODM industries because you’ll want something that will last a long time without being damaged.

And if you’re like most of us, you’ll want something light in weight and easier to work with. That is just what you can get in an aluminum machining service.

Because of its lightweight feature, it helps you in two different ways. The first one is that transportation is less costly and more comfortable because of its strength.

Second is it saves a lot of fuel when used in cars, trucks, railways, and airplanes by adding less weight.

Using it for vehicles is a good idea for another reason. When an accident happens, the vehicle’s aluminum structure absorbs most of the impact or shock inflicted by the crash and secures the passenger.

The aircraft industry is heavily dependent on aluminum machining service for various reasons other than saving fuel. Aluminum helps the aircraft to be airproof, which makes the aircraft more comfortable and safe. And to be lightweight and fly fast.

Other than vehicles, aircraft, and ships, many industries get benefited from aluminum machining services, like construction, food processing, packaging, and so on.

How to Choose a Reliable Aluminum Machining Service Provider in China?

You probably already know how to find and choose reliable manufacturers in China. But let’s see a quick recap. And after that, you’ll find additional factors that you’ll need to consider while choosing the right aluminum machining service provider.

As you know, first, you have to find and qualify the manufacturers and make a shortlist. Then verify them, see if they are legit or not. After you’re satisfied with their company and their presence, arrange a factory visit.

And the last part was the most important. Because a lot of people tend to avoid visiting the factory. If you don’t have the time or don’t want to do it yourself, you can always hire or send someone else.

You’re probably wondering why it’s the most important of so many. The reason is when you do factory visits; you get a clear idea of their production plant, workforce, current and previous work, past clients, and most importantly, their CNC machine.

Even if you can’t make a factory visit, know what type of CNC machine are they using. Because this can make all the difference. If a manufacturer uses low-quality machines with only limited capabilities, the final product won’t be right.

You’ll need to put more emphasis on the CNC machine your chosen manufacturer is using. If they’re using the latest technologies and skilled engineers for their production, you’re in good hands. And if not, then you need to choose a better alternative.

But keep in mind that no matter how reliable your chosen manufacturer is, always keep communication with them. Because in this way, you’ll get to know what’s happening with your order and when exactly you’ll be receiving it.

How does Sunrise Metal Ensure Optimum Quality when it comes to Aluminum Machining Service?

One of our core competence is we believe in quality. In Sunrise Metal, the quality of your goods is our responsibility. Our quality control team makes sure that we’re delivering the optimum quality goods to our customers worldwide.

Our first stage of ensuring quality starts with choosing the right raw materials and perfect alloys for production. We never compromise the raw materials to make more profits. We deliver more quality products to get more customers.

Second is our well-equipped CNC machines. These fully automatic computer-operated machines can do magic and make any shapes you want. The precision is absolutely accurate and clean, exactly how you want them to be.

The third is our qualified engineers and workforce. They work very hard to provide what you wanted. We don’t take shortcuts; hard work is our only mantra.

The fourth and final stage is our quality control team. Our QC team starts the action as soon as you place the order. We don’t wait for the production to finish to check the quality. We ensure the quality is optimum in every stage of the production.

Our team starts checking of the raw materials, seeing if the raw materials are suitable for your specific project. Then in every stage of the process, we’ll check and verify all the variants to ensure the quality that you desire. At the end of the process and throughout quality control, we do the final check before releasing the final goods to you. And our great team of quality control examines the goods in every angle and make sure you are receiving the optimum quality products and get complete satisfaction.

What is the Cost of a Custom CNC Aluminum Machining Service?

The cost of your custom CNC aluminum machining service depends on many variables. You might be searching the web for a solid answer but got no result. Or asking manufacturers for quotes and still be confused.

Don’t worry. You’ll get a clear direction now.

The reason why you’re not getting the right answer is that you’re asking the wrong questions. Manufacturers can’t give you a proper quote unless they have your design and requirements. Let’s have a look at the factors that affect your cost.

Design: The cost of your machining service begins at the design stage. Although CNC aluminum machining requires little to no labor for operating, they still need a design engineer; Who will design and digitalize the design for the machine.

This part can add a lot of weight to your budget. While designing, make sure you’re not choosing a very complex design. The more complex and critical your design is, the higher your cost will be.

A complex design will cost more on designing and digitalizing. But on top of that, it costs way more on production. Because complex parts will take more time and raw materials to manufacture. Which will bump up the cost significantly?

Equipment: The tools that require for your project also plays a vital role in your budget. Manufacturers often charge customers for the hourly rate on their machines. The rate of the machines is different from one another based on their capabilities.

For example, 3-axis machines have a lower hourly rate than 7-axis machines. If you need a quotation for our pricing, please feel free to give us a knock.

Raw Material: Another important factor is your raw material. Different types of alloys are used for machining. But depending on your project, the cost of alloy can make a difference.

For instance, Aluminum 6061 is the standard alloy used for automotive, textile, and other industries. This alloy costs less per block than other alloys like 7075—the weight is lower as well, so it also saves the shipping cost.

On the other hand, if you’re ordering CNC aluminum machining service for the aerospace industry, you’ll need Aluminum 7075. And this can be costly compared to the other one. Because this alloy costs more per block than others. Almost three times than Aluminum 6061. It also weighs more, so more cost the shipping.

Finishing: Often you’ll need finishing for your products. You could avoid finishing for some of the products, but it’s better and often necessary to have a surface finish. And that could cost you some additional money as well.

Shipping Cost: Shipping costs will largely depend on the weight of your products and the distance. You’ll want to have a fair amount of time to ship the goods to your location. Because emergency or fast shipping can cost you a large amount of money.

What Process Do They Use in Aluminum Machining Service?

There are different types of CNC machines to choose from. As the technology evolved, new methods were added to make this machine even more compatible. Some of them are:

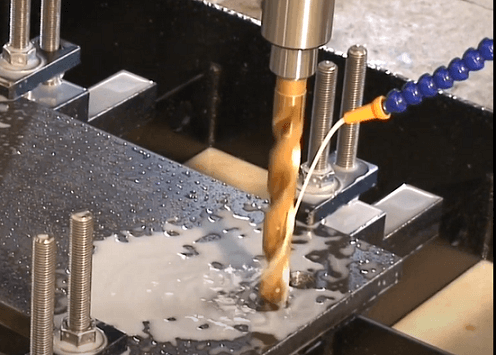

Drills: Drills work by spinning the drill bits against the surface and subtracting materials by its rotation speed.

Turning: This might be the earliest process of CNC machines. The capability of turning has been increased significantly over the years. But still, it has limited applications compared to other processes like milling.

In this process, the workpiece is held by the machine against a drill bit. This process is more suitable for subtracting a large volume of material that does not need high precision.

Milling: Unlike turning, in this process, the workpiece is held stationary. This CNC machine has a cutting tool that rotates on a spindle. The milling machine looks kind of like a drilling machine but works differently and a lot more advanced.

This is the most used machine in CNC machining and complex parts are usually machined with this process.

Grinding: This method is only used when a flat surface is required. In this method, the workpiece is mounted on a table, and a spinning disk spins and cuts the workpiece’s surface.

These are the most convenient ways of machining aluminum. Other than that, there are several different ways of machining for specific projects. Like Plasma cutting machine is used to machine steel materials. Electrical discharge machining is another process that is often used for cutting different kinds of complex holes and shapes into hardened steel material.

What is The Minimum Wall Thickness in Aluminum Machining Service?

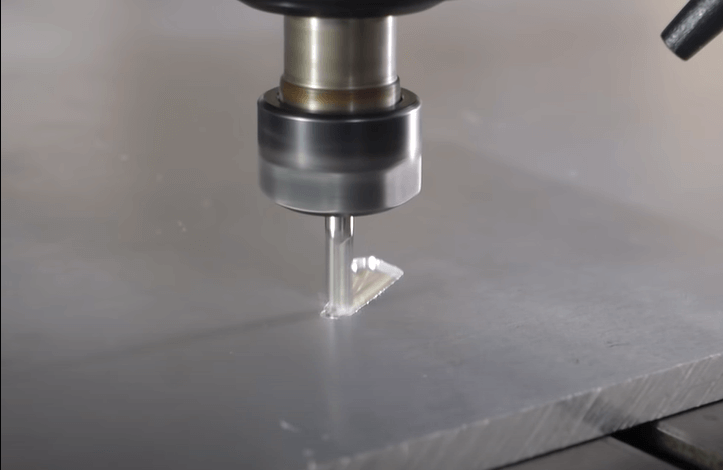

Designers and engineers always try to push the limits of making the parts lighter, thinner and more versatile. But there’s always a limit. And if the limit exceeds the part’s quality will be jeopardized.

The wall thickness may be dependent upon the CNC machine itself. Depending on the capability and quality of the machine the wall can be made thinner than that. Also, lower-quality machines cannot make a wall as thinner as a high-performance machine could.

What is the Difference Between Steel Machining Service vs. Aluminum Machining Service?

Machinability is the first and most significant difference between these two materials. Aluminum has superior machinability and workability when it’s compared to iron or steel material. It can be machined and shaped easily with any CNC method. It chips easily and takes a shorter time to machine.

Compared to aluminum, steel machining can take up to 3x or 4x more times to complete the process. Because of their lack of machinability. Aluminum is easier to cut, which makes them faster to be machined and reduces the lead time.

Other setbacks of steel machining are that steel is heavier in weight and contains less thermal conductivity. In comparison, Aluminum has the highest thermal conductivity and less weight than steel or iron alloys.

Aluminum saves time and effort by being one of the most workable materials among them. It is way faster to machine and polish aluminum than to steel or iron. Besides having a lower melting point than steel or iron materials, you can use aluminum’s electrical discharge machining at a much higher rate than other materials like steel.

And because of these reasons, aluminum machining can be the most effective option for most cases. However, there are projects where steel machining is mandatory. In general, aluminum beats the other options.

What is the MOQ for Aluminum Machining Service?

There is no standard MOQ for Aluminum Machining Services in China. Different companies have different requirements for MOQ. Usually, bigger companies won’t be interested in low-volume orders, and small companies can’t provide the aluminum machining service that you desire.

This is where Sunrise Metal can help you. Sunrise Metal is the leading company in China with precision machines and multiple production plants. We welcome low volume and high mix. No matter how low your volume is, we believe in quality, not numbers.

With Sunrise Metal, you can order as low as one piece and thousand pieces as well. We don’t believe in one-time sales, rather we believe in long-term relationship-building with our customers. We welcome you to experience the royal service of Sunrise Metal and see what we have to offer your company.

What Tools Does Sunrise Metal Use in Aluminum Machining Service?

This process is completely automated. Although we need one technician to run the tolls smoothly, the aluminum machining service is completely automatic. And for this, we need highly advanced machines. Companies that invest more in machines can offer the highest quality aluminum machining service. If you’re interested in any company, first check out what tools they use to machine the materials, you’ll get a clear idea of their capabilities.

Sunrise Metal is fully equipped with all kinds of powerful and durable tools. These tools and our skilled workforce can ensure the best aluminum machining service for your company with the topmost quality and less cost. Our experience in this field speaks for itself.

We welcome you to visit our factory and see by yourself how we do it and how you can be benefitted.

What are the Benefits of Aluminum Machining Service?

Aluminum is a widely used material for machining services. For almost any industry and parts, aluminum can be a great choice for machining. Let’s see some of the major benefits of aluminum machining service:

Machinability and workability: Aluminum is a soft material by nature. As a result, it can be cut, shaped, and machined quite easily than other hard materials. It chips easily, making it easier to work for machining service. With aluminum, we can make more complex materials with less power. Which makes it even more suitable for any machining service.

Affordable and low cost: Aluminum is an affordable option when it comes to machining service. The price of aluminum alloys is way less than steel or iron alloys. Other than that being easier to machine and requiring less power, aluminum can be machined at a meager cost compared to other materials.

Corrosion Resistant: Aluminum offers excellent corrosion resistance quality. However, the different aluminum alloys or grades have other corrosion resistance abilities. The most used grade, Aluminum 6061, has an astonishing amount of corrosion-resistant quality.

Strength-to-weight ratio: Aluminum has an amazing strength-to-weight ratio compared to any other material. It is almost three times lighter than steel but has a fair amount of strength. As a result, the aerospace and automotive industry rely on this material heavily. Because they need the parts to be strong but lightweight, exactly like aluminum.

These play a major role in making aluminum a favorite for machining services. Other than that, it has several more qualities that make it even more suitable. Electrical conductivity and recyclability are two more factors that also are responsible for making the aluminum best choice for machining service.

Why Should I Choose Sunrise Metal for Aluminum Machining Service?

Aluminum machining service is one of the manufacturing processes where you need to be the most careful while choosing the company. Because it requires extensive care, state-of-the-art machines, a super-skilled workforce, a highly experienced quality control team, and strong leadership.

Because if your chosen company lack any one of those, your products will suffer and so will your company. Sunrise Metal, having 10+ years of experience in this field and serving 500+ global customers with 1000+ products, knows what you want.

Here, at Sunrise Metal, we understand what you require, and we work hard to make your vision come true. Many buyers, OEM/ODM companies, often need low volume or high mix productions. And we welcome them with wide hands.

Because no matter the quantity you order, you’ll always get the best quality of products from us. We believe in long-term relationships and not just one time off.

Our state-of-the-art tools are always available to make your design come to life. Depending on your project and design, we help you get the best final goods for your company. We help you in every step of the design and decision-making process. And let you be involved in the production process as well. Because we treat our customers as our partners, not just leads.

Our quality control teams ensure your products’ quality in every stage of production So you can enjoy the optimum quality goods that you can be proud of!

What is the Standard Lead Time for Aluminum Machining Service?

Lead time can vary significantly from manufacturer to manufacturer. It also depends on the project itself to a large extent. But as a general rule of thumb, for a low or medium-size order, expect around 10+ days lead time.

If the manufacturer has a skilled workforce, fast quality control team, and a fair number of required machines, the lead time should be lower and vice versa.

It depends on your order as well. If your design is too complex, your project requires rare raw materials or complex parts to manufacture; it will take a longer time. Also, a large volume of orders can cause more lead time than a low volume.

When you’re placing an order with any manufacturer, ensure that both of you’re clear and agreed upon the final goods’ delivery date.

What are Some Product Examples of Aluminum Machining Services?

Aluminum machined parts are now widely used throughout various industries. Some examples of them are given below:

- Auto parts * Aircraft parts

- Engine Parts * Lighting parts

- Electrical equipment *Medical tools and devices

- Kitchen tools *Door handles

- Marine parts *Textile equipment and tools

- Sanitary products *Hardware tools

Why Do Manufacturers Use Lubrication in Aluminum Machining Services?

Lubrication plays a significant role while machining aluminum. It helps to cool down the heat that is generated by the friction. It also helps the chips not to get attached to the tool and removes the chips from the point of friction.

Before choosing the lubricant, manufacturers need to ensure that they are compatible with the aluminum and don’t cause any corrosion. It should also be anti-bacterial and environment-friendly.

Why Sunrise Metal Uses High-Speed Machining for Aluminum Machining Service?

As the name sounds, high-speed machining allows the spindle to remove the material at a higher speed than conventional machining. Being fast meaning more efficient production and less lead time. You might think the quality or finishing is poor in HSM. And you’d be wrong. High-speed machining can generate high precision results, because of their low pressure and higher vibration stability.

With HSM, the use of coolants is reduced. The reason is quite strange, although being faster should generate more heat, in that case, after a point, the temperature goes down as low as 200 degrees. Needing no extra coolants.

With high-speed machining, the tools also live longer. Because of the saved worked hours as a result of fast production. It also enables us to continue production at a much cheaper rate than conventional machining.

These are the primary reasons why Sunrise Metal uses the HSM strategy to machine your parts. We are committed to higher accuracy, cost-effectiveness, and minimum lead time. With this strategy’s help, Sunrise Metal can achieve its goal and make the customers happy.

How to Increase the Efficiency in Aluminum Machining Service?

One of the significant ways of increasing efficiency is to adopt high-speed machining technology. This enables manufacturers to speed up manufacturing up to 3 times compared to the conventional machining method.

Having said that, there are many factors that need to be improved to increase efficiency. From the initial stage to the last stage, an efficient strategy should be implemented.

At Sunrise Metal, our goal is to provide the best quality product in a short period. So our customers don’t have to wait long for the products and can continue their project with the finished product. This is why lower lead time is our topmost priority.

We try to be as efficient as possible from the earliest stages. From the discussions to the design period to production, we have to be extra careful not to delay time unnecessarily. Design is important, but you need to have a proper design and consulted with a professional designer, and approved by our team of skilled designers.

Because a lot of the time, defective design can eat up a lot of time if not addressed carefully at first. Another important factor is the complex design. If you have less time in hand, don’t choose a complex design that will require a longer time to machine.

Other than these technical factors, many things go with the management and leadership of a company. Companies like Sunrise Metal have years of experience and skilled technicians to make the process the most efficient. An inexperienced or less capable company cannot provide you with an efficient service up to your expectations.

What Surface Finish Can Sunrise Metal Offer in its Aluminum Machining Service?

Surface finishing is required after die casting or machining. But depending on your specific project, the type of surface finishing will differ. For example, finishing for lighting parts and automotive parts won’t be the same. Because they have different aims to achieve with surface finishing.

Being a one-stop solution, Sunrise Metal offers a wide range of surface finishing for you. We have cleaning, shot blasting, sandblasting, Powder Coating, Chromate, anodizing, Electroless Nickel, Silk Screening, Pad Screening, Laser carving, etc.

Depending on your project, we not only provide technical support but as well as advisory support for our customers.

What Quality Management System Does Sunrise Metal Have?

Sunrise Metal is an ISO 9001 and IATF 16949-certified company. We maintain all the quality guidelines and requirements to produce the optimum quality of our product and get ultimate customer satisfaction.

All our process activities go through strict quality control guidelines that eliminate all defects and issues. Our relentless quality control team works ahead of time and ensures that quality is maintained at every step.

From the beginning to the end of the process, there is no scope for compromising our products’ quality. Because we believe in quality more than anything. Before releasing the product, our strict quality control team double-check the final good quality, ensuring you don’t get any low-quality products.

Conclusion:

When it comes to CNC aluminum machining service, you don’t want to take chances. You want someone who can take care of your needs and make your design into an exact physical design.

This is where Sunrise Metal comes in. We take care of your design and make the best quality product according to your requirements. Our products are unbeatable. Because we don’t take shortcuts.

Our latest technology, machines, and skilled workforce can make the project a lot easier and more comfortable for you. Our engineering process and strategy will provide you with valued-suggestion and make product improvements for your projects.

Warmly welcome you to visit us and contact us if any requests on aluminum machining projects.