YOUR EXPERT CHROME PLATING ALUMINUM SUPPLIER IN CHINA

Sunrise Metal is wholly equipped for eliminating issues of distortion, offering the standard stability and durability characteristics. Furthermore, for aluminum-based tools, our chrome plating aluminum enhances the life-span of these components and offers improved working efficiencies.

Regularly, the restoring of a used aluminum part with chrome plating is able to spare you up to 60% of the cost as compared to the cost of a new aluminum part. And it gives function-ability and durability that is equivalent or exceeds that of the new aluminum part.

For a cost-effective and more effective solution as well as, an ultra-hard surface, chrome plating aluminum is in a class of its own.

Among the aluminum parts are regularly protected from the scrap pile, and able to chrome plate that can extend the durability and quality of the are hydraulic pistons, cylinders, rolls, dies, molds, and other aluminum parts that weren’t machined appropriately.

SUNRISE RICH CAPABILITY MANUFACTURING EQUIPMENT FOR YOUR CHORME PLATING PROJECTS

How Sunrise Aluminum Surface Finishing Capability Ensure Your Project Success

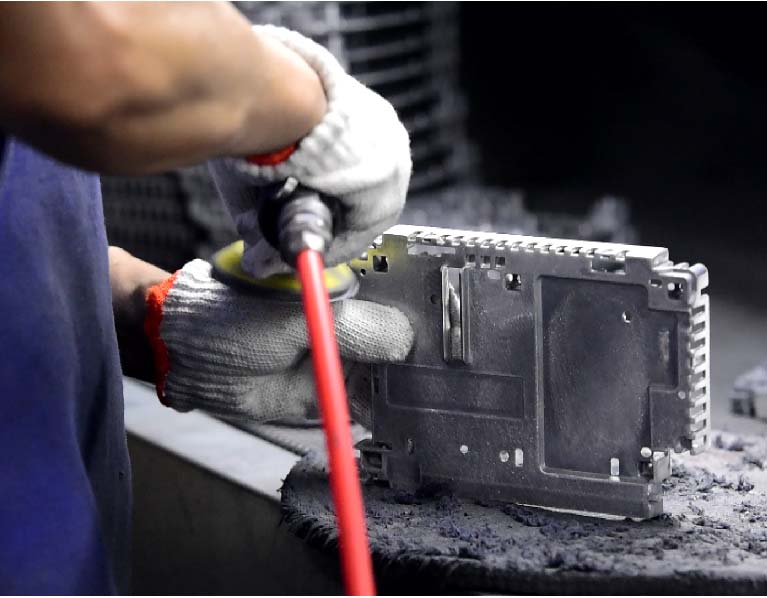

Sunrise Metal perceives the significance of clearing before aluminum coating in our plating procedure. Furthermore, in-order-to achieves the required and standard level of visibility and cleanliness, most aluminum parts are treated with great care.

To guarantee appropriate bonding and a superior wear-resistance surface, chrome plating must be professionally poured in the aluminum pores.

Chrome Plating Aluminum is an art to us that benefits from our extensive, industrial expertise in metallurgy, metalworking, and plating.

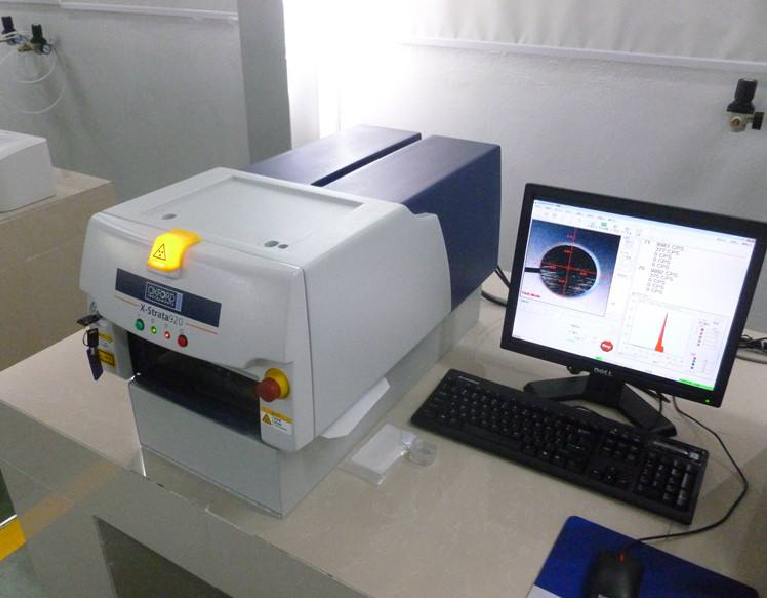

With the efficient production flows to the thorough inspection and high precision quality measuring lab in house, we support the chrome plating aluminum parts batch production with on-time delivery.

The finishing for chrome plating aluminum parts we are providing is compliant with ROHS & REACH.

1000+ DIE CASTING PARTS SURFACE TREATMENT EXPERIENCE FROM 500+ GLOBAL CLIENTS

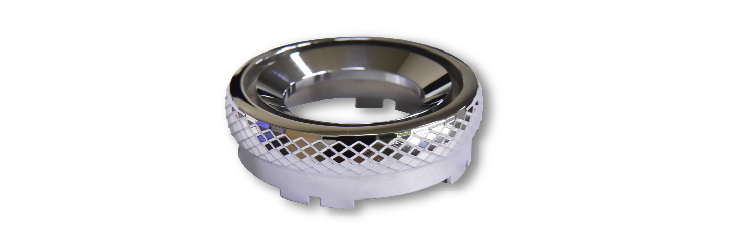

RECENT CHROME PLATING ALUMINUM PARTS

Sunrise Metal develops complete solutions for aluminum parts with chrome plating finishing and manufacturing for 10+ years. For now, the projects we are completing with our customers are as follow:

- Advanced Equipment

- Premium Quality

| No. | Name | Stroke | Q’ty |

| 1 | Mazak 7-axis turning&milling Machine | Ø658*1011MM | 1 |

| 2 | Mazak /Hass 5axis CNC machine | Ø850/Ø600 | 4 |

| 3 | 3-axis CNC machine center | 2000*1500MM | 1 |

| 4 | 4-axis CNC machine center | Ø250*800MM | 8 |

| 5 | 3-axis CNC machine center | 1000*600*600MM | 20 |

| 6 | CNC Lathes | Ø320*800/Ø610*1000MM | 2 |

| 7 | Sodick Wire cutting Machine | 400*400*200MM | 3 |

| 8 | EDM machine | 500*400*400MM | 2 |

| 9 | Surface grinder | 600*300*200MM | 1 |

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

GET A FREE CONSULTATION

Receive advice directly from engineering consultants for your Chrome Plating and Electroplating Parts. Our suggestions and solutions are based on your CAD and Step drawings.

CHROME PLATING ALUMINUM:

THE COMPLETE FAQ GUIDE

Sunrise Metal 24-hour services are available to you by contacting us with your specific chrome plating aluminum related needs or requirements. We perceive that technology is continually evolving, and this remains constant for chrome plating aluminum.

What’s more, to guarantee that our industry remains updated and adopting technology rapidly, we utilize both standard chrome plating aluminum and high-quality and exceptionally productive chrome plating aluminum.

This enables us to give the most prevalent coating facilities from China on each activity and the most cost-effective solutions in the industry today.

- What is Chrome Plating Aluminum?

- What is the Process of Chrome Plating Aluminum?

- What are the Benefits & Advantages of Chrome Plating Aluminum?

- What are the Applications of Chrome Plating Aluminum?

- What to consider when choosing a Chrome Plate Aluminum Service?

- How is Chrome Plating applied to Aluminum?

- What items and parts require Chrome Plating Aluminum?

- What is Hard Chrome Plating Aluminum?

- What is Decorative Chrome Plating Aluminum?

- What is the difference between Hard and Decorative Chrome Plating Aluminum?

What is Chrome Plating Aluminum?

Chrome Plating Aluminum is an exceptional technique of electroplating a layer (thin-layer) of chromium onto an aluminum part or product. Aluminum and its alloys are lightweight, moderately durable, and cheap; they are broadly utilized in an assortment of regions.

However, they are delicate materials, so they are dependent upon anodization treatment. Specifically, for parts that become altogether worn or require durability, mold release, or surface smoothness, these properties can be allotted to aluminum surfaces by applying chrome plating.

We apply chrome plating that can successfully adhere directly to all aluminum alloys. The chrome plating aluminum can be of two types, hard chrome plating or decorative chrome plating. However, these both offer strong resistance against corrosion, ease cleaning, and surface hardness increment on different levels.

It’s challenging to avoid seeing, using, or coming into contact with a product, part, or object that is made of Aluminum a whole day. This incredible and exceptionally lightweight metal can be found in everything from aircraft and vehicle parts and objects to drink and food containers.

Aluminum is a significant business: The Aluminum Association researched; Aluminum’s immediate economic effect is more noteworthy than $75 billion every year. While considering the effect on providers and other related industries that utilization aluminum — metal finishing organizations, for instance — the complete surpasses $186 billion.

What is the Process of Chrome Plating Aluminum?

In many manufacturing applications, it is useful — and on certain occasions, necessary — to apply an extra coating onto an aluminum part for purposes, for example, expanding corrosion protection, giving more prominent wear resistance, or improving the appearance of an item.

Chrome Plating Aluminum is considered as the most exceptional metal finishing technique that can accomplish every required and essential customers’ objective. The process of Chrome Plating Aluminum includes immersing the Aluminum alloy into an electrolytic solution and acquainting the electric current in-order-to store broke ions of another metal onto the aluminum parts’ surface.

The chrome plating aluminum process typically includes the following stages:

- Degreasing process to remove the heavy soiling

- Cleaning (Manual cleaning) or evacuate every external surface element

- Applying different pre-treatments depending on the substance and the alloy in use

- Afterward, the aluminum part processed further through chrome plating vat, where the heating and warming process is triggered

- The finishing step is to get the ideal and standard processed part thickness

There can be a majority of variations to the described process depends on the type of aluminum alloy is being chrome plated. Various aluminum alloys need distinctive carving arrangements.

What are the Benefits & Advantages of Chrome Plating Aluminum?

The different aluminum alloys offer the engineers many exceptional advantages and benefits in their product design; however, some of the crucial benefits & advantages of Chrome Plating Aluminum are the following:

- Freedom of Design – New and updated parts and products can be easily manufactured using the lightweight Aluminum combined with the chrome plating finishing and durability

- High level of hardness and abrasion resistance

- Low friction coefficient in aluminum parts

- Prevents seizing & galling

- Wear Life – The exceptional hardness of aluminum parts after chrome plating is from 65 to 70 HRc, and the durability it offers against corrosion and wear of aluminum parts is of great value

- Different degrees of gloss

- Low Coefficient of Friction – After applying chrome plating on aluminum parts, their friction reduced to 0-5%

- Restores the dimensions of undersized parts

- Extends in-service equipment life and reduce costly downtime

- Excellent Adhesion – Sunrise Metal offers exceptionally powerful bond strength of chrome plating on all aluminum alloys

- High level of resistance to corrosion

- Temperature resistant up to approximately 350°C

What are the Applications of Chrome Plating Aluminum?

Chrome Plating Aluminum may give off an impression of being a stylish and unique finish. It offers an appealing, quality, and attractive finish for an extensive library of aluminum products and parts, chrome plating aluminum surfaces are ideal for the majority of industrial applications, including:

- Hydraulic cylinders and equivalent other hardware products

- Auto and mechanical components and parts

- Compressors and Mining equipment

- Great for kitchen utensil design requirements

- Aerospace and marine industry applications

- Tooling and agriculture parts

- Shafts

- Parts and objects used in textiles and printing industries

Furthermore, the above are some standard applications of chrome plating aluminum. You have a great choice to contact our team at Sunrise Metal to get familiar with different applications or to examine your particular chrome plating aluminum needs and requirements.

What to consider when choosing a Chrome Plate Aluminum Service?

With regards to picking the best chrome plating service, you may confront a troublesome decision. Chrome plating is valuable, yet the correct choice for you relies upon how you intend to utilize the plated aluminum part or component. The following mentioned points are what you should consider when choosing the best chrome plating aluminum service:

- Wear: Will the use of the part cause it to wear down after some time? The probability of a part wearing out is impacted by how regularly it’s used and different objects it comes into contact with.

- Environment: What sort of conditions will you utilize the part in? Consider whether it will be exposed to moisture, extreme heat, or cold and other environmental factors.

- Motion: Is the chrome-plated aluminum component a moving part that needs or requires to operate smoothly without wearing down? A part that gets stuck or fail can slow down or damage the processes and damage equipment.

- The shape of the substrate: Are the shape of the thing to be plated moderately smooth and uniform, or is it unpredictable? Check for holes, spaces, unusually shaped parts, and unpleasant surfaces.

How is Chrome Plating applied to Aluminum?

Chrome plating is a professional and skilled act of electroplating a layer of thin chrome onto parts manufactured using Aluminum and is ideal if applied by an experienced and skilled aluminum finishing industry like Sunrise Metal.

Firstly, the nature of the raw Aluminum is surveyed just as the ideal aftereffect of the finish. At that point, the raw Aluminum is stripped to uncover the exposed particles, and all dust, liquid (oil & paint), and old plating are evacuated and eliminated.

Secondly, the raw Aluminum is polished in-order-to eliminate any kind of scratches and impurities to get a perfect and smooth surface finish.

Thirdly, Sunrise Metal offers an additional corrosion resistance layer and cleaning lines by adding copper plating before re-polished and cleaning (surgical) once more.

Fourthly, to improve the profound brilliance appearance of chrome and another protection layer, nickel plating is applied. At that point, the aluminum parts got processed through a chrome plating vat to warm them by temperature solution, and the electroplating process happens. However, for the amount of time and effort, it got placed into this solution is to get an ideal and standard thickness of plating.

At the last stage, polishing the processed aluminum parts, and the surface is cleaned once again and examined for standard quality and required finish.

What items and parts require Chrome Plating Aluminum?

Chrome plating aluminum is typically applied to everyday items and auto parts, it has been widely applied on CNC precision machining and aluminum die casting parts, including:

- Door handles, knobs, and letterboxes

- Shower fittings, washroom taps, and latrine flush

- Chains, towel rings, and holders

- Interior and outside lighting

- Interior and outside vehicle parts

- Motorcycle parts

- Press parts and devices

- Valves and Molds

Overall, chrome plating aluminum is considered as essential for parts made from Aluminum that require resist rust, scratches, and other different flaws.

Most importantly, meet to a member of our team at Sunrise Metal for more information and guidance related to chrome plating aluminum or to examine and discuss your requirements and needs related to chrome plating.

What is Hard Chrome Plating Aluminum?

The process of hard plating aluminum is an exceptional one that includes applying a chromium layer to the aluminum part surface by placing the part in a corrosive chromic solution.

This process of hard plating aluminum is able to enhance the durability, hardness, wear resistance, and corrosion resistance of the aluminum part. This way, the aluminum part can be used for heavy and intense machinery works and hardware.

Furthermore, it’s conceivable to apply chrome plating on aluminum parts without changing or altering the domain properties of the parts – store it in the exact thickness fundamental for a particular application.

Hard chrome plating is known for its hard surface from 68 to 72 Rockwell C, exceptionally resistant to wear and corrosion, lower friction coefficient, and smooth surface and ease of cleaning. The following are some crucial benefits of using hard chrome plating, including some of its exceptional properties:

- Superior Hardness

- Durable Thickness

- Low Deposition Temperature

- Wide Range of Bases

- Excellent adhesion

- Low Friction

- Variety of Finishing Options

However, these benefits of commercial chrome plating aluminum can enhance the existing properties of aluminum parts for more effective and productive use in many industrial applications.

Sunrise Metal boosts the productive and beneficial properties of their hard chrome plating by modifying the plating thickness for enhancement and increasing the aluminum part hardness and durability. Furthermore, hard chrome plating offers the most benefits a project requires against every other surface finishing technique.

What is Decorative Chrome Plating Aluminum?

Decorative is a tasteful feature and an exceptional chrome plating type; however, it additionally provides strong corrosion-resistance and wear-resistance. Furthermore, the decorative chrome plating layer is narrow – from 5 to 8 micrometers maximum when applied to aluminum parts. Furthermore, it offers fine durability but not much as compared to hard chrome plating aluminum.

However, it has its unique features and benefits. If you end up asking, ” For how long the decorative chrome plating layer can protect the aluminum part?” you ought to know that its layer is thin and can wear off after some time. The following are some of the exceptional benefits it offers:

- Improved Appearance

- Exceptional Corrosion Resistance

- Easy Cleaning

- Great Resistance against Wear

For industrial and general applications where durability and functionality are core requirements and essential, it can be used easily and its functionality is admired. However, its attractiveness and resistance against corrosion can improve numerous customer products.

What is the difference between Hard and Decorative Chrome Plating Aluminum?

The primary difference between decorative and hard chrome plating aluminum is the chrome plat finishing layer thickness and the different benefits they hold as a protective coating.

However, the hard chrome plating aluminum layer is thicker as compared to decorative chrome plating and is valuable in numerous industrial applications for its strength, wear resistance, corrosion resistance, and other gainful properties.

Decorative and hard chrome plating aluminum results from a similar manufacturing process, yet contrast in their last properties and basic applications.

Chrome plating utilizes an electrolytic process that applies chromium plating to aluminum parts in an electrolytic bath solution at a rate of approximately 25-30 microns per hour. At first, the aluminum parts are cleaned entirely, and, if required, the grip of the chrome plating is enhanced by treating the part with chemicals.

The aluminum parts at that point are processed through a chrome plating vat, where chromium is applied on the surface of the parts with the help of an electric current. This process applied the two kinds of chrome plating to aluminum parts of every shape, size, and surface, including the incredibly complex ones.

Decorative and hard chrome plating aluminum is able to cling perfectly to rigid or level the aluminum surfaces. With plating vat, a chrome plating is applied to the aluminum parts of almost every size, shape, and surface.

The versatility of chrome plating aluminum settles on it a well-known decision for a broad scope of uses in manufacturing parts and general products.