Why Choose Sunrise as Your Diecast Aluminum Enclosures Supplier?

Are you looking for resilient, highly-dependable diecast aluminum enclosures to protect your sensitive electronic components, circuitry, and equipment? You can keep Sunrise Metal in your mind.

- Over 10 years of extensive professional experience for industries like Automotive, Marine Devices, Marine, Telecom, etc.

- Worked with big-ticket clients such as Cummins, Flir, Thales, and Mindray.

- As an all-in-one solution manufacturing company, we follow an efficient system that covers all the processes involved in the production – from prototyping, tooling, die casting, CNC machining to surface finishing. This ensures a faster production turnaround and delivery of your orders.

- ISO 9001 & IATF 16949 certified company, follow strict quality control in all process manufacturing.

Sunrise Al Diecast Enclosure Manufacturing Capability

Sunrise Metal continuously invest in top-notch technologies and facilities to cover all the processes involved in creating custom-fit cast aluminum enclosures for large-scale applications. This eases your supply management process, saving you more time to deal with other important matters in your business.

In-house Facilities: We have 4 dedicated facilities that house 182 professional employees, which we believe is the right company size for your annual aluminum die casting volume requirements. And we have a tooling shop where we fabricate and calibrate our tools. This is to ensure that your products meet the highest standards of quality, precision, and performance.

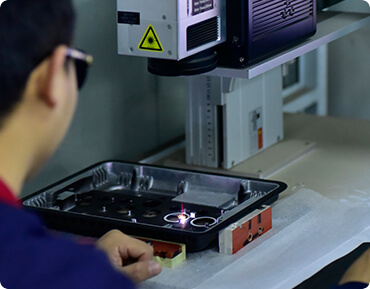

Software: Our engineering design team uses mold simulation analysis and CAD software to fine-tune our products. We have high regard for excellence, thus, we put great attention to detail. The use of digital technology helps our engineers provide accurate measurements and configurations of your custom-fit diecast aluminum enclosures and make it 100% fit for production.

Machinery:Our factories are outfitted with high-precision & reliable diecasting machines and measuring equipment. We already have 16 innovative patents awarded by the government.

Prototyping:We can also guarantee a fast production of your prototype through our very own 3D printer. This accelerates the whole planning process so we can start the production process as fast as possible.

Our Diecast Aluminum Enclosure Technology and Production Equipment

Recent Enclosure Projects

Part Name: RADAR BASE PLATE

Material: AlSi12

Size: 535*520*50mm

Weight: 15000g

Machine Tonnage: 1600T

Surface Finish: Chromating

Production Process: Die Casting–Trimming–Deburring

–CNC Machining–Chromating

Applied Industry: Maritime

Part Name: RADAR COVER

Material: AlSi12

Size: 409*233*314mm

Weight: 5050g

Machine Tonnage: 1250T

Surface Finish: Powder Coating

Production Process: Die Casting–Trimming–Deburring

–CNC Machining–Chromating–Powder Coating

Applied Industry: MARITIME

Part Name: HAND SHANK FRAME

Material: AlSi12

Size: 356x222x43 mm

Weight: g

Machine Tonnage: 500T

Surface Finish: Coating

Production Process: Die Casting–Trimming–Deburring

–CNC Machining–Chromating–Powder Coating–Liquid Painting

Applied Industry: MEDICAL

Part Name: AUTOMOBILE INTAKE TUBE

Material: ADC12

Size: 451x138x125 mm

Weight: g

Machine Tonnage: T

Surface Finish: Chromating

Production Process: Die Casting–Trimming–Deburring–Shoot Blasting

–CNC Machining–Leakage Test–Chromating

Applied Industry: AUTOMOTIVE

Part Name: CAMERAL LAMP COVER

Material: AlSi12

Size: 109x109x41 mm

Weight: g

Machine Tonnage: T

Surface Finish: Coating

Production Process: Die Casting–Trimming–Deburring

–CNC Machining–Powder Coating

Applied Industry: MARITIME

DIECAST ALUMINUM ENCLOSURES:

THE COMPLETE FAQ GUIDE

Diecast aluminum enclosures, also known as aluminum housing, have box-like structures. They are designed with the purpose of ensuring the protection of sensitive electronic devices and equipment in a wide range of working conditions such as industrial and commercial environments.

- What is a diecast aluminum enclosure?

- How are diecast aluminum enclosures prepared?

- What are the key features of diecast aluminum enclosures?

- What are the different applications of diecast aluminum enclosures?

- Which types of aluminum enclosures, boxes or housing parts are made using the diecast process?

- Why are diecast aluminum boxes preferred over enclosures made from other alloys?

- Are diecast aluminum enclosures and boxes aesthetically more pleasing than other such boxes? How?

- How cost effective are diecast aluminum enclosures for industrial use?

- Are diecast aluminum boxes waterproof?

- Do industrial electronics make use of diecast aluminum enclosures? Why?

- Why do telecommunication companies require diecast aluminum enclosures for their electrical parts?

- Which factors determine the durability and lifespan of a diecast aluminum enclosure?

- How can we deal with any downsides associated with the use of aluminum diecast enclosures?

- What are the technical specifications of diecast aluminum enclosures manufactured by Sunrise?

- How does Sunrise ensure quality and safety while producing diecast aluminum enclosures?

What is a diecast aluminum enclosure?

Diecast aluminum enclosures are technologically engineered to prevent damage to electrical equipment from dust and water with the help of their watertight seals. These housings are integral for safety of equipment in harsh climatic conditions. Their weatherproofing eliminates the possibility of damage from heat or water.

The diecast enclosures, due to their use of aluminum, are electrically conductive and are easy to ground. This quality plays an essential role in preventing electrical fires and eliminating shock hazard.

Their modern, industrial design also offers protection from Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) preventing damage to electronic devices.

How are diecast aluminum enclosures prepared?

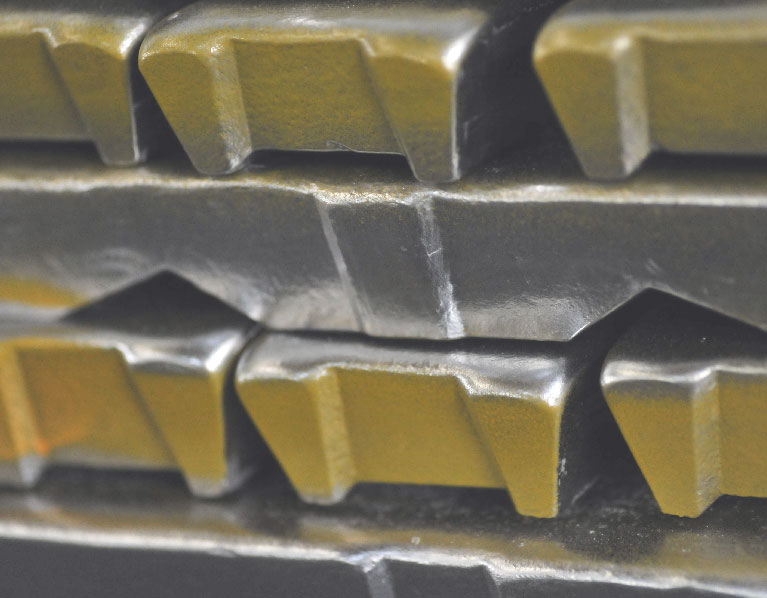

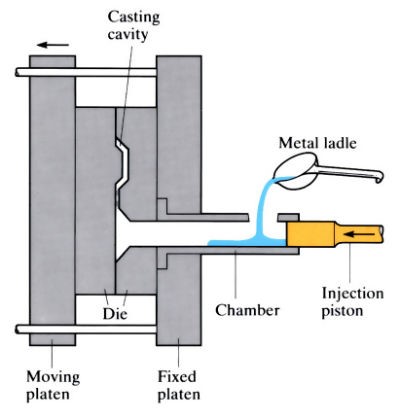

The die casting process is a metal casting technique that forces molten metal into a mold cavity under high pressure.

Diecast aluminum enclosures are prepared using the same method, in which the mold produces a box-like structure to meet specifications. Metals are hardened to produce the desired shape, using one of the two most popular techniques: cold-chamber or hot-chamber diecasting.

Since aluminum is a high-melting point alloy, the cold-chamber method is more suitable. This is because it uses a separate chamber to heat the metal and then transfer the molten metal to the casting machine.

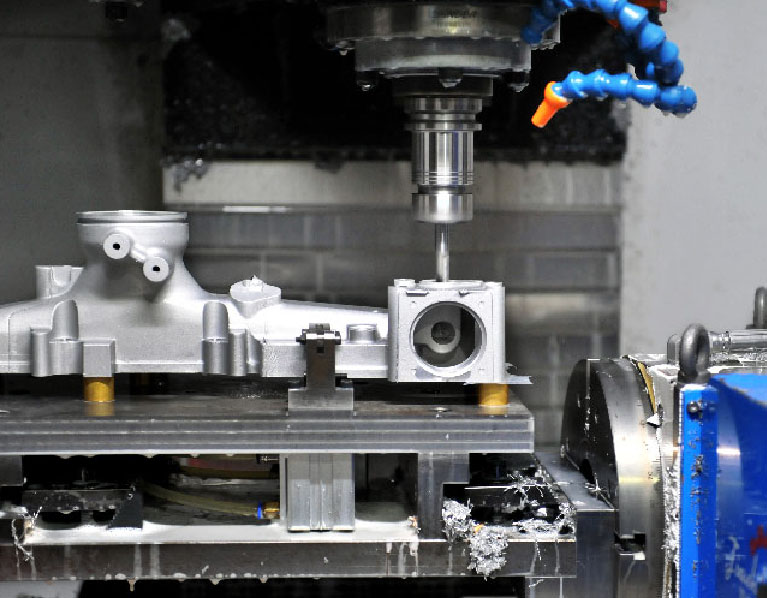

The manufacturing process allows for high-volume production due to minimum finishing and machining requirements. Sunrise produces aluminum enclosures with machining, stamping and assembly. A variety of supporting features are also provided such as molded gaskets, powder-coated surfaces, fasting threads and recessed lids, along with shielding to prevent it from corrosion.

There can be some variations that can be introduced in both hot-chamber and cold-chamber such as:

- Low pressure die casting

- Vacuum die casting

- Squeeze die casting

- Semi-solid die casting

What are the key features of diecast aluminum enclosures?

The neoprene gasket in the diecast enclosures provides a watertight seal. This ensures they are waterproof so the contents cannot be damaged by water particles. Hence, the diecast aluminum enclosures are ideal for outside use such as network junction boxes, telecom enclosures, etc.

Additionally, the following features are unique to these enclosures:

- Diecast aluminum enclosures offer high resistance to corrosion and shock resistance which makes these products long-lasting.

- The convenient grounding of these enclosures also increases their life-span.

- The low-maintenance required by aluminum and its alloys further boosts its endurance.

- Their ability to survive in a wide variety of weather conditions, including harsh climates increases endurance.

- They are ideal for use in temperatures ranging from -20°C to +100°C.

- They have an Ingress Protection rating (IP) 66.

Diecast aluminum enclosures also have high thermal conductivity. This allows for favorable passive heat dissipation that prevents overheating of the electrical equipment it contains.

What are the different applications of diecast aluminum enclosures?

Aluminum enclosures can be used in an extremely wide range of industries including automotive, telecommunication, aerospace, medical, and other commercial industry.

Diecast aluminum enclosures protect electrical components in a diverse range of environments including construction, industrial and utility applications. These include junction boxes, switching, meter cases, filter networks, and other forms that require a small box.

Due to the technologically engineered features of these housings, they are used in circuit breakers, control panels and switches found in all types of industrial and commercial buildings. The electrical conduction and grounding offered by these enclosures as well as its waterproofing makes them ideal for such uses.

These are specially used in places where a safety enclosure is needed in concealed or other indoor uses. We offer aluminum enclosures in a different box sizes with close-fitting covers.

In the telecom industry, the electrical equipment required to transfer data across vast distances is sensitive to environmental conditions, such as wireless transmission boxes on cell towers.

The extensively enclosed housing defends electrical cables and components against potential threats from the outside. It also elevates efficiency and ease of use by keeping equipment organized inside.

Furthermore, such enclosures limit accessibility of the equipment they contain to authorized personnel only. This aids in the avoidance of accidents and harm resulting from interference by those without authorization as well as theft.

Which types of aluminum enclosures, boxes or housing parts are made using the diecast process?

There are a number of diecast aluminum enclosures and boxes that are made. Here’s a comprehensive list:

- LED lighting enclosures – these benefit from waterproof properties of diecast aluminum

- Electrical units – these are used in junction boxes and elbows with high-strength applications

- Disk drives – these are in high demand by computer companies for lightweight features

- Metal Chassis – these protect circuit boards and cool electronics in outdoor settings

- Cable TV amplifiers – these aluminum housings increase the signal from cable station to end-user

- Telecom enclosures – these are used as wireless boxes for transmission and mounted on cell towers

- TV frames – these are rigid and durable frames that help protect electronics behind the screen

Why are diecast aluminum boxes preferred over enclosures made from other alloys?

Diecast housing made from aluminum and its alloys have higher durability in comparison to enclosures manufactured from other materials. This is due to the resistance of aluminum to corrosive reactions unlike zinc’s corrosion in acidic and alkaline mediums.

Another factor contributing to the reliability of these diecast aluminum enclosures is the lack of reactivity of this metal. All of this offers maximum protection to the enclosure itself and its contents from external threats.

When compared to other metals and their alloys, aluminum’s light weight is another beneficial factor. Aluminum’s weight is only one third of that of steel while offering the same, if not more, strength. It allows for efficient and more affordable transport of aluminum products over great distances via a range of transportation modes. It also makes the process of unloading and loading smoother to carry out as no extra measures are required.

Moreover, its weight increases the convenience of diecast aluminum enclosures application, in both personal usage and the industrial sector as aluminum is easier to manage than alternate metals and alloys.

The aluminum used in the diecast enclosures provides a natural barrier to these electromagnetic waves (EMI and RFI) and protects electrical equipment from malfunctioning or failing.

These qualities of aluminum enhance the protection diecast enclosures offer to all sorts of electrical appliances and devices that is unmatched by any other alloy

Are diecast aluminum enclosures and boxes aesthetically more pleasing than other such boxes? How?

The diecast aluminum enclosures, owing to their use of this durable alloy offer smooth, silver surfaces with an impressive finish. This innovative finish adds to their aesthetic appeal, making these housings suitable for many uses.

Such uses include LCD frames for which the housings are ideal, as they not only provide the required sturdiness and support, but also a modern looking exterior.

This aluminum exterior does not require high maintenance to maintain its natural silver shine. On the other hand, steel enclosures require regular upkeep in the form of paint for an impressive finish as they are susceptible to corrosion that can ruin outward the appearance of the housings as well as damage the interior.

Similar to steel, iron enclosures also react with moisture in the air overtime and form flaky, red-brown oxides on its surface, marring its appearance. Such issues are avoided with the use of diecast aluminum enclosures as they are resistant to deterioration over time as they are nonreactive. This ensures a first-rate exterior that is aesthetically pleasing and impressive to look at.

How cost-effective are diecast aluminum enclosures for industrial use?

Diecast aluminum enclosures are made affordable and highly cost-effective due to the combination of a variety of reasons.

Relative to other processes, these housings require minimal manual labor for assembly processes. As the process is highly mechanized, it is cost-efficient and economical for large scale uses such as for those in the industrial sector. In addition, industries can take advantage of economies of scale.

The diecast process at Sunrise employs high-tech machinery and expert engineers which add to the cost-effectiveness of the final products. Large volumes of enclosures for industrial use can be prepared at a low cost, but with high precision and detail. The preparation and tooling costs are also managed efficiently, making it suitable for a wide range of applications.

Moreover, the process of manufacture of diecast aluminum housings is more efficient and consumes less time when compared to the manufacturing times of other products. This well-structured process saves valuable time and allows for the costs to be more economical as it allows for increased levels of productivity.

As an alloy, aluminum is extremely durable and low maintenance, leading to low overall costs. Furthermore, aluminum is one of the most abundant metallic elements available. It eliminates possibilities of price surges due to shortages and allows manufacturers to maintain a reasonable and consistent price in the market.

For harsher settings, such as use in saline waters or water treatment plants, aluminum boxes prove to be higher versatile. They are coated for high resistance, making them immune to corrosion. Aluminum can achieve high level of ingress protection, much more than their plastic counterparts.

Are diecast aluminum boxes waterproof?

Diecast aluminum boxes survive well in outdoor conditions, even in a diverse range of climatic conditions including snow and rain. This is possible due to the waterproofing of these housings to prevent entry of water particles that could lead to damage to the contents of these enclosures.

Extensive waterproofing is ensured in these housings by the use of neoprene gaskets. Also known as polychloroprene, these gaskets are impermeable and thus restrict entry of particles of gases and liquids, including water.

In addition to water, the gaskets provide resistance on many fronts including but not limited to resistance to combustion, sunlight, ozone, chemicals etc. In combination with the durability of these neoprene gaskets, insulation of water particles is guaranteed in nearly all circumstances and conditions.

Furthermore, the water-resistant quality of the diecast aluminum enclosures is enhanced by the use of aluminum alloys. When exposed to water, a film of aluminum oxide forms that protects the underlying material from corrosion and vulnerability to leaks.

Do industrial electronics make use of diecast aluminum enclosures? Why?

In the industrial sector, there is immense use of electronic equipment and mechanical accessories both indoors and outdoors. A majority of these devices are vulnerable to malfunctions and failure if left unprotected.

To safeguard these components against external threats such as dust, rain, hail and extreme levels of heat, enclosures are required. This is integral to ensure the smooth working of the electrical devices without potential interruptions caused by damages.

The diecast aluminium enclosures provide a watertight exterior with the use of neoprene gaskets that is vital for the weatherproofing of circuit boards. These enclosures are specifically engineered with cutting edge technology to endure through the harshest of environmental conditions.

Furthermore, uses of these housings in the vastly spread out range of industries include traffic lights, audio equipment, generators and lighting. These diecast aluminum enclosures also defend automotive electrical control units and make under the hood applications more convenient to carry out.

Why do telecommunication companies require diecast aluminum enclosures for their electrical parts?

In the telecommunications industry, there is a high level of usage of electrical equipment and accessories as transfer of data relies on it. This usage is spread over a variety of regions, including both indoor and outdoor environments such as:

- Data centres

- Office environments

- Server and comms rooms

- Internet server providers (ISPs)

- Mobile operators

- Residential areas

To ensure an uninterrupted flow of data, the equipment that is susceptible to damage from external conditions must be offered protection in each of the areas of use mentioned above, in a variety of ways to meet all the needs.

The high standard diecast aluminum enclosures defend electrical cables and components against potential threats from the outside including dust, water in the form of rain and snow, extreme heat etc. This secures the contents of the extensively enclosured housing against any damage and any malfunctions that may occur as a result.

Additionally, the housings protect against potential accidents and resulting harm to public welfare if high voltage equipment is left unenclosed.

Which factors determine the durability and lifespan of a diecast aluminum enclosure?

The innovative engineering of the diecast aluminum enclosures includes the use of materials of the highest caliber to ensure long-lasting products. They can endure even the harshest of circumstances, and lasts even longer than steel.

The metal shaping technique that produces aluminum enclosures is also a key factor in determining the quality of the end product. The diecast process is ideal for the production of complex parts, such as in automotive or electronic parts. Thinners, lighter walls not only make the product appealing, but also add to the durability and strength.

Sunrise makes use of the best aluminum alloys such as A380, due to their high strength and long lifespan. The use of aluminum in the manufacture of these housings is due to the fact that it offers the best combination of properties.

These abilities, such as its lack of reactivity, allow it to have a significant lifespan unmatched by other metals and their alloys. This allows the enclosures to preserve their high dimensional stability and offer reliable protection to the electrical components they house.

Moreover, aluminum is a low maintenance alloy as compared to other alloys, making it even more economical to use. It does not rust, and can be used for a variety of outdoor finishes, electronic equipment and other industrial components.

Also, the housing is naturally corrosion resistant. This maintains the structure of these enclosures guaranteeing durability and reliability even in alkaline and acidic mediums and in the presence of water.

How can we deal with any downsides associated with the use of aluminum diecast enclosures?

Diecast aluminum enclosures come with a variety of advantages and beneficial qualities that make it desirable over other products. The possible downsides associated are a few in number and can be easily overcome.

One potential disadvantage can be the high cost of this process of manufacture when done on a small-scale. However, this matter is resolved when production is carried out on a larger, industrial scale. The advantage of economies of scale can be availed and cost of production is minimized as high production efficiency is attained.

Another prospective issue that may arise is that of porosity, which is the presence of voids or unfilled spaces that can affect the stability and density of the enclosures. Porosity can be formed due to several factors. So, it is important to take care of all the possible causes to keep the percentage of porosity to the minimum. Sunrise Metal has advanced quality control equipment and experienced engineers, who are experts in dealing with porosity.

Here’s a detailed explanation of how porosity can be dealt with.

Controlling the temperature

Proper design for manufacturing

Machine Operating

Sunrise is a one-stop provider of diecast aluminum solutions, and caters to all types of suppliers. If you demand customized services but at a low scale, our team of engineers will be ready to design a process that suits your demand.

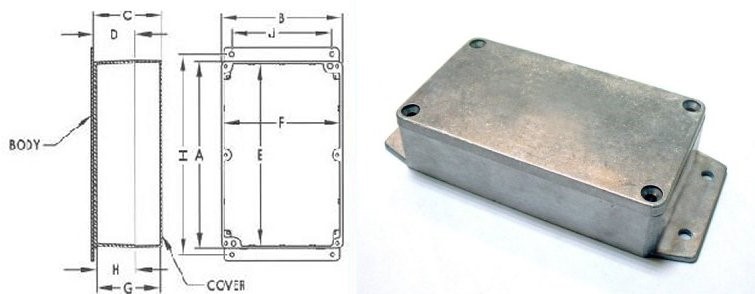

What are the technical specifications of diecast aluminum enclosures manufactured by Sunrise?

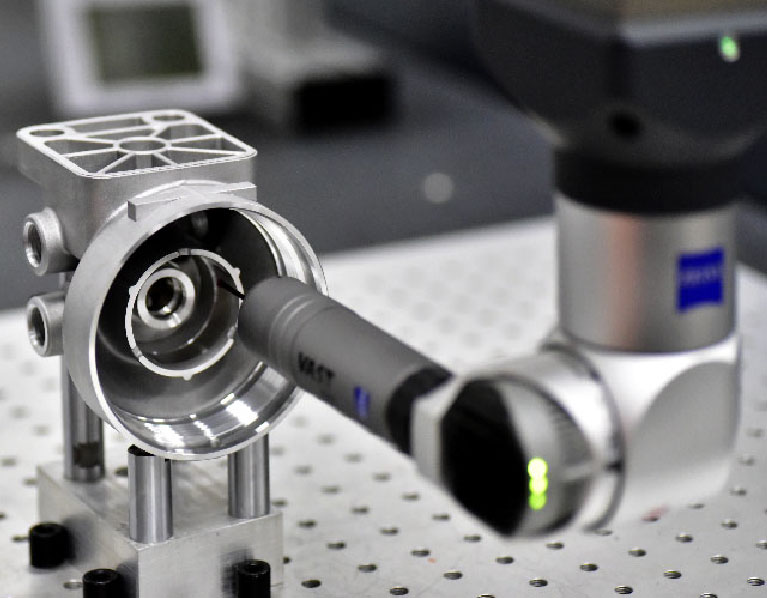

As a leading manufacturer of aluminum diecast enclosure, Sunrise has paid special attention to the maintenance of strict technical specifications, attributes and parameters.

The boxes and housing are shielded, and an optimal weight is maintained to provide maximum efficiency for industrial components. The height, length, thickness and width are pre-determined to ensure that all products comply to consistent standards.

At Sunrise, all boxes are lead-free and ratings are maintained, such as the IP rating of IP54. Natural color is maintained as well, making it suitable for use in a variety of settings. These are high-tech products engineered through advanced technology and top machinery.

The end product meets international standards and satisfies customers by meting customization requirements. We supple enclosures with holes, openings and other markings/cut-outs to tailor the product according to customer specifications.

How does Sunrise ensure quality and safety while producing diecast aluminum enclosures?

Sunrise is ISO 9001 and IATF 16949 certified.

These international guidelines provide pathways to the production of world-class industrial components. In order for aluminum enclosures to be applied to a variety of outdoor and indoor applications, we pass them through rigorous tests.

We have out in place stringent organizational and product standards that are followed meticulously to maintain our reputation as world-class suppliers. We supply safe boxes with mounting brackets and covers, crafted with high rigidness and strength.

Mounting holes and covers with screws are designed so that they prevent any moisture and dust from entering the boxes. Each part of the product, including body, cover, gasket, screws, and mounting hardware, is prepared to give the aluminum enclosures the best finish.

Our products are high-grade with IP rating 68 certified by independent laboratory testing, establishing its waterproof properties. Our team of expert engineers work with high levels of precision to ensure that no single part goes to waste, or fails to comply with the given standards. Complying with safety and operational standards makes these enclosures highly suitable for use in extreme working conditions.

We produce top-rate, high pressure diecast aluminum enclosures that cater to customized orders. Our specialized machinery determines the functional use of these aluminum housing and is available in natural shades. Various types of sensors and mounted terminal blocks can be housed in the enclosures, providing maximum product support.