WHY SUNRISE METAL

Sunrise Metal, a China-based aluminum die-casting manufacturer, is located in the Shanghai-Suzhou region. With over 10 years of experience, 3 facilities, and 182 skilled professionals, we provide comprehensive and cost-effective solutions for all your aluminum die-casting needs.

- 1-Stop precision aluminum die casting manufacturer

- ISO 9001 & ISO 13485 & IATF 16949 certified

- Use of advanced technology like vacuum die cast, semi-solid die cast, and massive venting technique

By choosing us, you can save costs and run your projects more smoothly. Contact us with your next project.

ONE STOP CAPABILITY

Our 1-stop aluminum die casting manufacturing service starts from rapid prototyping to quality surface finishing. We help you get your aluminum die-casted parts in one place.

- Rapid Prototyping

- Die Casting Tooling

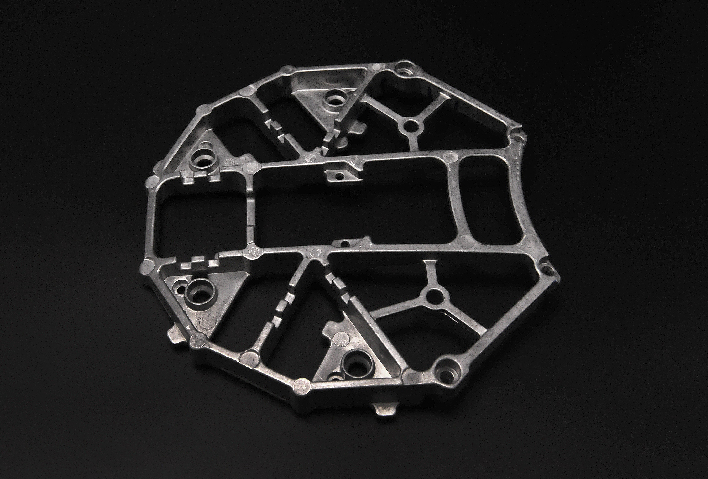

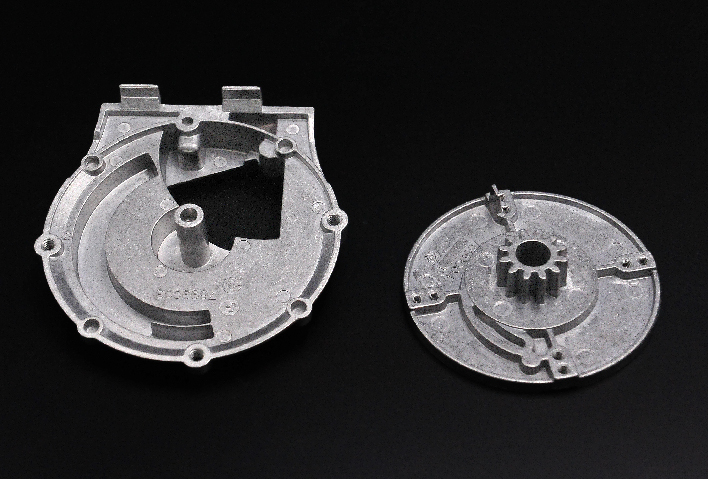

- Aluminum Die Casting

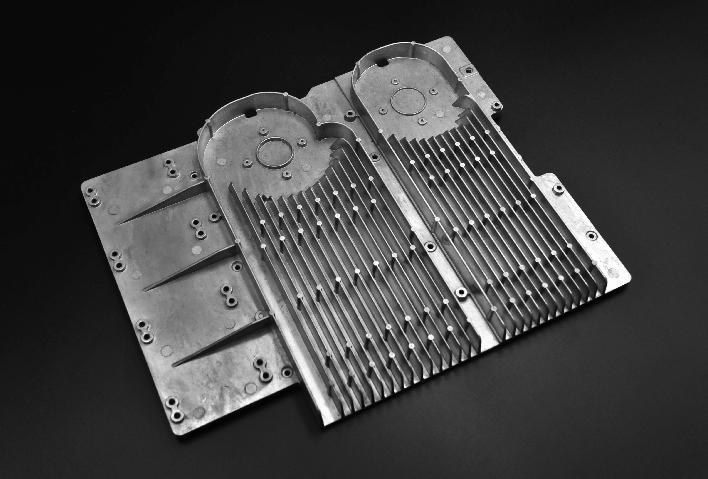

- CNC Machining

- Surface Finishing

Rapid Prototyping

We have CNC prototyping services. The wide range of materials includes:

Plastic: ABS, PC, POM, PMMA, Nylon, etc.

Metal: Aluminum, Zinc, Copper, Stainless Steel, etc.

Equipped with a different number of axis machines, which can meet your low to medium volume demand, verify your design, fabricate your parts, and reduce your time to market.

Our major prototyping equipment includes:

| Name | Q’ty | Stroke |

| Mazak 7-axis CNC Machine | 1 | Ø658*1011mm |

| Mazak/Hass 5axis CNC machine | 2 | Ø850/Ø600 |

| 3-axis CNC machine | 1 | 2000*1500mm |

| 4-axis CNC machine | 8 | Ø250*800mm |

| 3-axis CNC machine center | 16 | 1000*600*600mm |

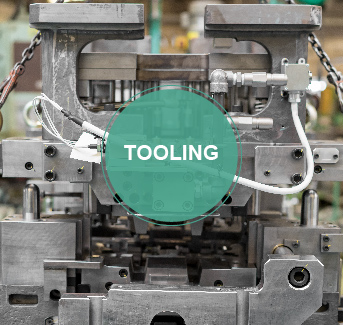

Die Casting Tooling

The in-house tooling shop allows us to do the die-casting mold design, mold Fabrication & mold maintenance in the same workshop.

Our mold engineers will review your drawings and propose suggestions by mold flow analysis, which can help you prevent potential issues or risks that may happen in later production.

| Name | Q’ty | Stroke |

| EDM | 8 | From 438mm to 1100mm |

| CNC | 5 | From 850mm to 3015mm |

| Wire Cutting | 2 | 800*630mm |

| Milling Machine | 4 | 1000*800mm |

| High-speed Cutting Machine | 1 | 750mm |

| Grinder | 4 | From 380mm to 1600mm |

| Lather | 1 | 1000mm |

o>

Aluminum Die Casting

Sunrise Metal has been focusing on precision aluminum die casting. It’s worth saying we own a remarkable engineering team with over 23 years of professional die-casting experience. This enables us to provide excellent technical support to customers.

We produce precision die-cast components and products with our promised lead times in the industry. To ensure high-quality products and processes, we continuously implement the latest technologies.

| Name | Q’ty | Tonnage |

| Die Casting Machine | 2 | 280T |

| Die Casting Machine | 1 | 300T |

| Die Casting Machine | 2 | 400T |

| Die Casting Machine | 2 | 500T |

| Die Casting Machine | 1 | 630T |

| Die Casting Machine | 2 | 800T |

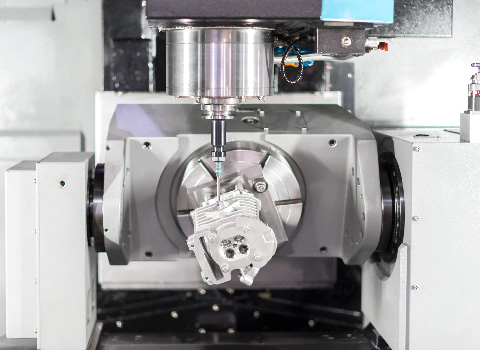

CNC Machining

Sunrise Metal not only processes die-casted parts but also provides machining from solid, extrusion, gravity casting, forging, etc. The high-tech engineering and precision machines allow us to provide a precise and highly accurate CNC machining service according to your requirements.

We are good at high-precision machining products. The highest positioning precision is ﹢/﹣0.0015(JIS B6336). Welcome to your high-mix, low to medium-volume projects.

| Name | Q’ty | Stroke |

| Makino F5 3-axis CNC | 2 | 900*500mm |

| Makino A51NX 4-axis CNC | 1 | 900*600mm |

| Makino 5-axis CNC | 1 | Ø850/Ø600 |

| 3-axis CNC machine | 1 | 2000*1500mm |

| 4-axis CNC machine | 8 | Ø250*800mm |

| 3-axis CNC machine | 14 | 1000*600*600mm |

| CNC Lathe | 1 | Ø320*800mm |

| CNC Lathe | 1 | Ø610*1000mm |

Surface Finishing

We have a cleaning and shot blasting service in-house, which can give a matte look to your die-casting parts and machining parts. We also have outsourced suppliers close to our factory to offer other finishing:

Anodizing provides a clean, uniform, corrosion-resistant coat normally for machined products.

Powder coating & liquid painting have a corrosion-resistant layer and meet different appearance requirements

Silk screening, pad screening, and laser carving provide an ID or logo recognition.

ENGINEERING SUPPORT

We can help customers with the following:

- Design for Manufacturability (DFM) to ensure the feasibility of products.

- Simulation Moldflow Analysis to predict mold filling, solidification, and cooling for reducing the risk of defective die-casted parts.

- Value engineering solutions to reduce costs throughout the manufacturing process.

- Process control and the whole Production Part Approval Process (PPAP) package to ensure consistent quality.

With these engineering services, we can help you save time and money while ensuring high-quality products.

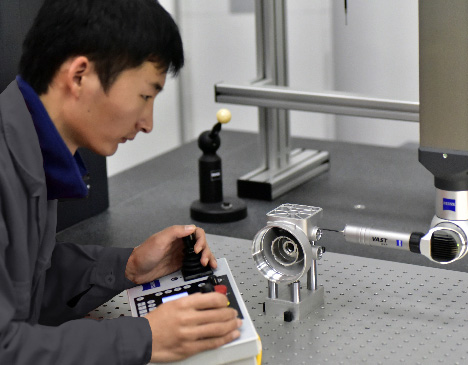

OUR QC SYSTEM

OUR QUALITY CONTROL

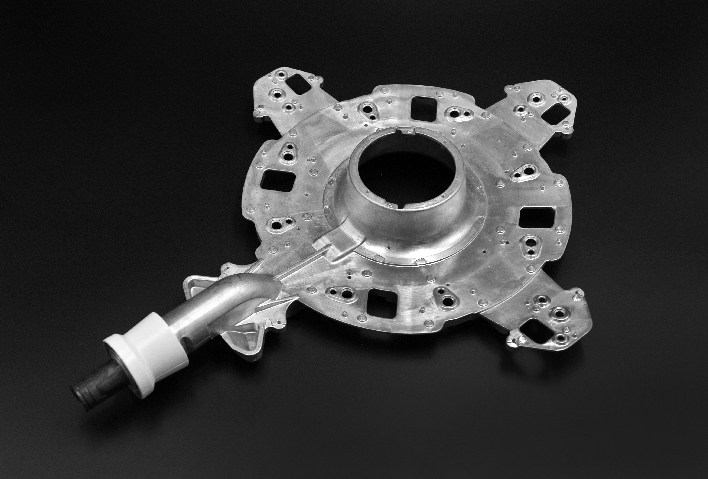

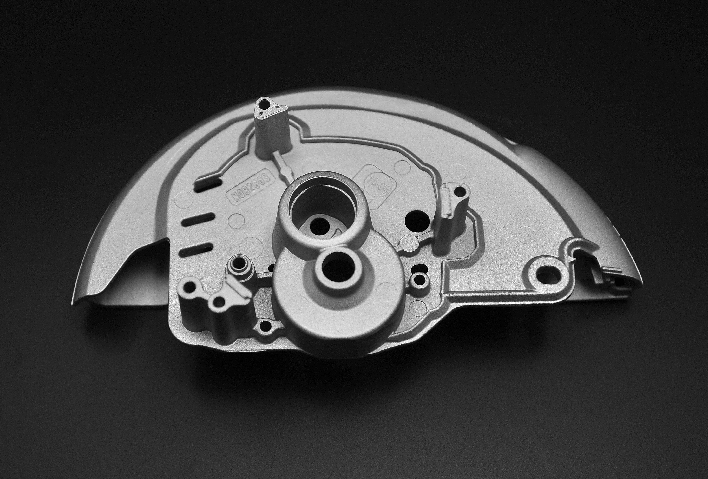

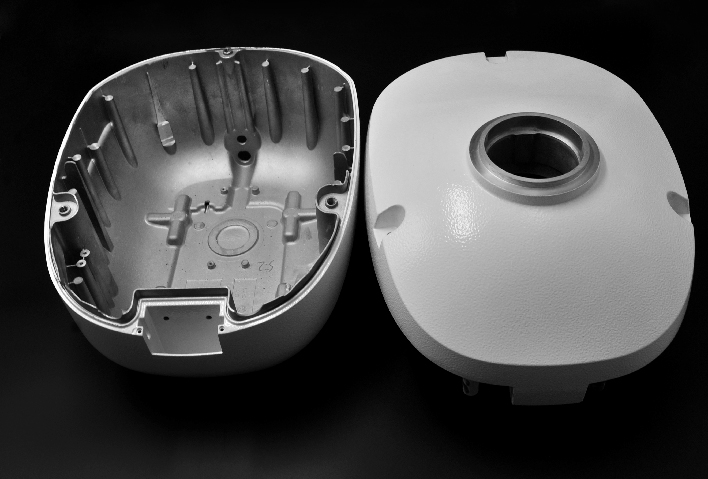

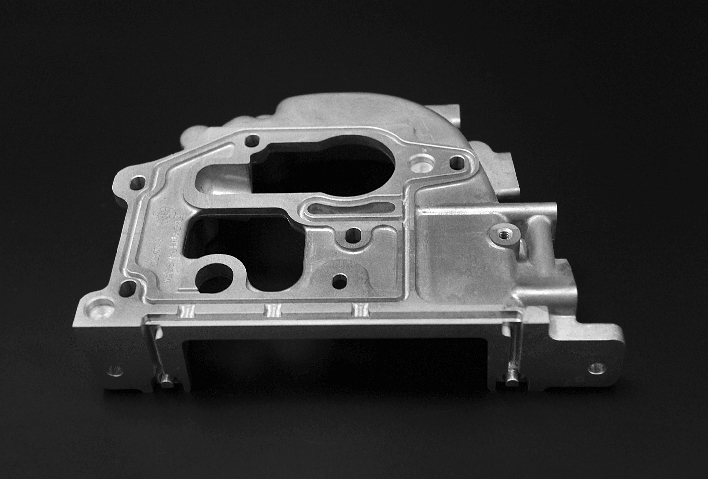

PROJECT GALLEY

- Applied in Medical Equipment Industry

- Lawnmower’s part from General Industry

- Components for Marine Electronic

- Components for Automotive Industry

- Applied in Medical Equipment Industry

- Power Tools from Ggeneral Industry

- Component For Communication Industry

- Components of Medical Equipment

LISTEN TO THE VOICES OF OUR CLIENTS

I am very appreciated. The BK products that you folks support are on an upswing, so hopefully, 2020 will be prosperous for both companies. I also want to thank you for your support in cost reductions and pulling in deliveries. Much appreciated.

Sunrise never let me down, whatever the new projects or current ongoing parts. They do have rich experience and this great help. I like their perfect DFM, really fast, and on-time delivery.

Thank you, the quality is very well. I wish next year will be successful so that we can do more business with you.

PROUD SUPPLIER OF