NICKEL PLATING ALUMINUM ENHANCE APPEARANCE & DURABILITY

Nickel plating is the process of applying a nickel coating over metal parts by chemical reduction or electrolytic processes. Nickel Plating is an excellent surface finishing technique for both decorative and engineering purposes.

Nickel plating aluminum parts is particularly popular among manufactures for its multitudes of benefits. Aluminum is naturally electro-positive and compatible with nickel. So, Nickel plating aluminum is more straightforward and cost-effective.

Sunrise Metal provides full chain services on aluminum die casting from design to final treatment. Nickel plating is just one of the various finishings we offer. If you have any other demands on aluminum die casting projects, Sunrise Metal is always here for serving you.

Different Processes are Available for Nickel Plating

There are different options open for you to Nickel Plate your aluminum parts. These are mainly classified into the following two categories.

- Nickel Electroplating

- Electroless Nickel Plating

Each of the processes is quite different. We will be discussing these two processes of nickel plating describing their relative advantages, process, and application.

Nickel Electroplating Can be done on Metals Only

Nickel Electroplating is done by the reduction of cations by passing a current through an electrolyte solution of nickel. This deposits a thin layer of nickel over metals. But electroplating requires both the coating and the part to be metals.

I will be explaining the nickel electroplating process step by step,

- The parts should be heat-treated to reduce internal stresses and increase strength.

- Then cleaning, masking, pickling, and etching is carried out. It removes impurities such as dirt, defect, or corrosion and protects the parts during electroplating.

- Then immerse the metal part into an electrolyte solution with nickel dissolved in it. Here the metal acts as the cathode, and the dissolved nickel acts as the anode.

- Upon passing electricity through this electroplating setup, the nickel ions are reduced to metallic nickel and deposit into the metal’s surface.

Nickel Electroplating can have Different Characteristics Depending on the Chemicals Used

Nickel Electroplating can have different properties based on the type of nickel salt and buffer used as electrolytes. The following type of coatings can do characterization of nickel electroplating,

Nickel Sulfamate

It offers better dimensional corrections, corrosion protection, and wear resistance. So, it is better for engineering applications. Often It is used as a sublayer for chrome plating. Chemicals used are Nickel sulfamate, Nickel chloride, and Boric acid.

Watts Baths

The coating can be made either bright or semi-bright. The bright variants have better looks and moderate corrosion protection. In contrast, semi-bright coatings have better engineering properties. It uses Nickel sulfamate, Nickel chloride, and Boric acid for electrolysis.

Black Nickel

Most Nickel coatings have a metallic sheen. But Black Nickel plating is applied over bronze, steel, brass, etc. to form a non-reflective surface. It is mainly used for improving appearance rather than functionality. Nickel ammonium sulfate, Zinc sulfate, and Sodium thiocyanate are used as electrolytes.

Hard Nickel

It is just what the name says. It is harder than most other nickel-coating and has excellent tensile strength as well. Chemicals used for electroplating are Nickel sulfate, Ammonium chloride, and Boric acid.

All-sulfate

In an all-sulfate nickel plating, only Nickel sulfate salt is used for preparing the electrolyte, and Boric acid is used as the buffering agent. Such type of coating is used when the anode is insoluble in the solution.

All-chloride

All-chloride plating is similar to the all-sulfate plating, except a full Nickel chloride solution is used this time. The main advantage is that it can run at low voltages, which allows for a thicker coating. But, it also increases internal stress within the parts.

Sulfate-chloride

A Sulfate-chloride bath balances the pros and cons of both the all-sulfate and all-chloride processes. It offers a higher rate of deposition at a lower voltage, and the internal stress is also less than the all-chloride plating.

Each Type of Nickel Electroplating Has Specific Application

Nickel electroplating can achieve coatings with varying properties based on the chemicals used for electroplating.So, each type of nickel electroplating may be used as either a decorative coating or for engineering applications.

Nickel plating used for decorative purposes has a brighter and smooth finish. It has good resistance to corrosion and wears. Decorative nickel coating is preferred for exposed vehicle parts, such as the bumpers, exhaust pipe, etc.

It is also used in home appliances, plumbing fixtures, and other things where it is desirable to have a better appearance. But, nickel used for engineering applications focuses more on performance than looks.They offer better corrosion and wear resistance than a decorative nickel coating. They also induce less stress in dimensional recovery.

Electroless Nickel Plating is Applicable for Most of the Materials

Electroless Nickel Plating does not require any electricity. It is a chemical process and does not require any conductive material like an electroplating process. So, other materials such as plastic can be given nickel coating as well.

Electroless nickel plating is formed by an autocatalytic reaction. So, the coating is more uniform since there is no factor of uneven current density caused by the geometry of the part. The process for electroless nickel plating is described below.

- The desired part has to be thoroughly cleaned to void its surface impurities completely. A series of chemicals bath will be provided to remove different types of contaminants.

- Non-metallic or materials with low electropositivity will need surface activation first. The part is usually dipped into a solution of electro-positive metal to enable galvanic action.

- Then immersing the parts into the reducing solution will start the plating process.

The electroless nickel plating can be classified into two categories based on the type of nickel alloy used.

- Electroless Nickel-phosphorus Plating

- Electroless Nickel-boron Plating

Electroless plating is almost the same for both processes except for the reducing agent. The nickel-phosphorus plating uses a phosphorus-based reducing agent, while nickel-boron plating uses a boron-based reducing agent.

Electroless Nickel-phosphorus Plating is More Commonly Used in the Industry

The term electroless nickel plating is often synonymously used with electroless nickel-phosphorus plating. Nickel-phosphorus Plating is used much more often compared to other electroless nickel plating methods.

This process uses a nickel sulfate solution as the source and a hypophosphite salt as the reducing agent. But, some post-treatment is usually required to prevent oxidation or corrosion of the layer.

The metallurgical properties achieved by nickel-phosphorus plating can vary based on the percentage of phosphorus available in it. Therefore it is divided into the following types.

Low Phosphorus Coating

Such coating has a phosphorus content of less than 4%. The coating hardness is measured up to 60 units on the Rockwell C scale. Low phosphorus coatings mainly serve a decorative purpose.

Medium Phosphorus Coating

The coating may have a varying phosphorus content of about 4 to 10 %. The coating has better looks at a lower phosphorus content. But as the percentage of phosphorus increases its wear resistance, corrosion protection, hardness increases.

High Phosphorus Coating

The phosphorus content is around 10-14%. These coatings are preferred for very rough conditions. It has superior hardness than the rest, and so provides exceptional protection against corrosion and wear.

So, which one you need really depends on the scope of the application of your parts. Low phosphorus coating will be shinier and have better solderability. While high phosphorus content will reduce porosity and enhance the mechanical properties of parts.

Electroless Nickel-Phosphorus Plating has a Wide Range of Applications

Nickel-phosphorus Plating offers a great deal of hardness and provides excellent protection against wear and corrosion. And the finish quality is much smoother and uniform compared to other coatings.

It has widespread applications in many equipment and accessories. Some important applications include,

- It is used for many internal and external automotive parts such as shaft, rotor, valves, exhaust pipe, etc.

- Its shining look makes it a perfect fit for your home’s kitchen and bathroom fixtures.

- Its enhanced hardness properties are desirable for power tools, mechanical, and electrical equipment.

- It is very commonly used for smoothening the platter of hard disk drives.

- It has a significant use for salvaging old car parts.

- PCB boards also make use of this Nickel coating as well.

Electroless Nickel-Boron Plating Has Some Limited Uses As Well

Nickel-Boron Coating is amorphous and deposits into the surface of the part, maintaining a columnar structure. These columns are perpendicular to the surface and create a nodular topography.

Such texture helps to reduce the friction between two surfaces. It also allows for better heat dissipation and reduces drag for fluid flows. Usually, the coating will contain about 2.5-8% of boron.

For these properties, electroless nickel-boron frequently used in greaseless guns, propellers, saw blades, bushings, washers, pumping equipment, etc. Because these applications require parts with less friction.

Differences between Nickel Electroplating and Electroless Nickel Plating

Now that you have a better understanding of both of the processes let’s talk about the differences between these two methods. I will also discuss the relative advantages and disadvantages of Nickel Electroplating and Electroless Nickel Plating.

- Electroplating requires current flow through the electrolyte solution. But electroless plating is autocatalytic, and it will spontaneously take place without any current flow.

- Electroless Nickel Plating is uniformly coated into every recess of parts. But, in Nickel Electroplating geometry of the part will affect the current flow over different areas of the substrate. This results in non-uniform distribution of the coating.

- Electroless nickel plating usually offers higher corrosion resistance and hardness. This is particularly true for coatings with a high phosphorus content. Some form of electroplating can have good engineering properties as well.

- Electroless plating produces less internal stress in the parts than electroplating.

- Electroless plating has a higher cost of chemicals, and the need for automated devices will be observed in this process. On the other hand, electroplating requires sophisticated apparatuses. So, which one is more cost-effective depends on multiple factors.

Facts Why You Should Nickel Plate Your Aluminum Parts

Aluminum has many excellent properties that make it a good choice for manufacturing. Still, there are costlier alternatives available that may offer slightly better wear resistance and hardness than aluminum.

So, when your product applications demand that added benefits, should you go for an alternative? Maybe you don’t have to because Nickel plating can significantly improve the properties of your aluminum parts.

Some compelling benefits of nickel plating your aluminum parts are as follows,

- It improves the corrosion resistance

- Gives an aesthetic look to your parts

- Greatly Increases the wear resistance

- Has excellent hardness

- Can act as a base layer for other types of finishes

So, it is desirable to nickel plate your aluminum products for achieving these benefits. But, there are tons of other surface finishing processes similar to nickel plating. One such surface finishing method for Aluminum is Anodizing.

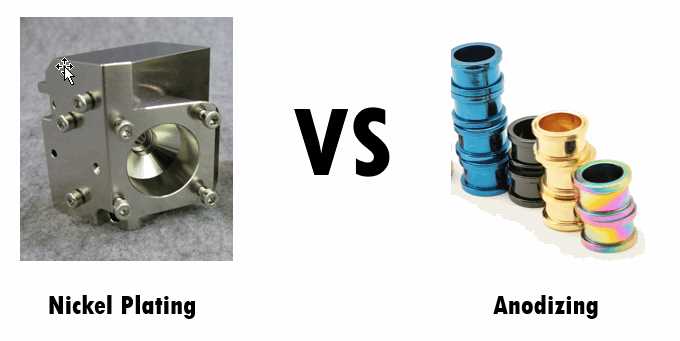

Differences between Nickel Plating Aluminum and Anodized Aluminum

Anodization and nickel electroplating are both electrolytic processes. But they work a little differently. Anodization is done by passing a direct current through an electrolytic solution, which ads an oxide layer on top of the aluminum part.

Do note that the layer is formed by oxide of aluminum itself and not another metal. Anodization does not alter the base metal, whereas nickel plating will cover the aluminum parts, thus altering its properties. Anodizing will leave micropores on the aluminum surface. The size of the pores is proportional to the voltage applied. Upon dyeing the parts with a suitable color, the pores will be filled by the pigments. An additional coating is applied to protect the colored finishing.

Anodizing will leave micropores on the aluminum surface. The size of the pores is proportional to the voltage applied. Upon dyeing the parts with a suitable color, the pores will be filled by the pigments. An additional coating is applied to protect the colored finishing.

As you can see, Anodizing will affect the surface of the substrate. And long term use will cause damage to the surface directly. So, repairing the parts keeping all structural properties unchanged becomes more difficult.

In the case of Nickel plating, the nickel coating will deal with most of the corrosion and wear. The metallic shine of nickel coatings also lasts much longer.