YOUR BEST FIT CNC PROTOTYPING MANUFACTURER IN CHINA

Sunrise Metal has one dedicated CNC prototyping Facility which specialized in CNC prototyping production. With over 23 years’ experience in CNC prototyping business, we succeed in our customer’s business with our best fit CNC prototyping parts.

We commit to offer you the best quality prototyping parts at a competitive cost.

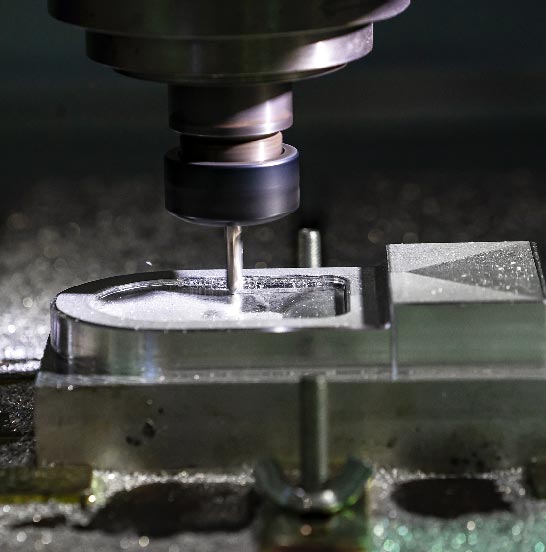

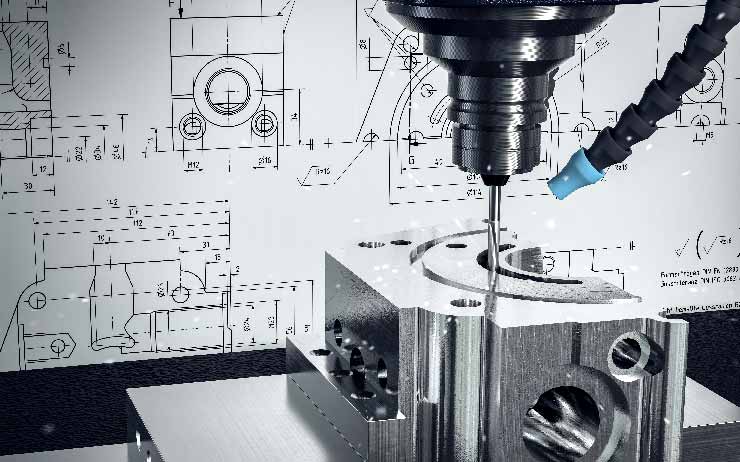

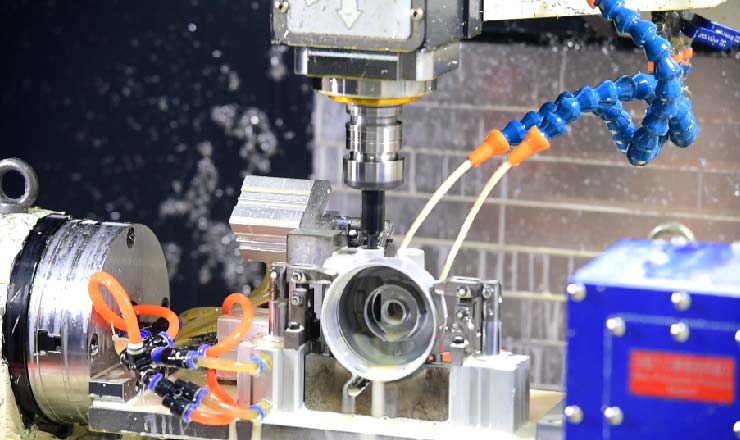

- Our high precision CNC machines, such as 5 & 7 axes turning & milling machines, can make extremely accurate and complex prototyping parts.

- We make CNC prototyping in a very fast way. 1-200 prototyping parts can be finished only 1~2 weeks.

- Equipped with two Carl Zeiss CMMs and other high accuracy quality equipment, which makes us deliver verified good quality parts.

- Sunrise Metal makes CNC prototyping parts with various materials including aluminum, zinc, Stainless steel, and plastic.

20+ YEARS PROTOTYPING PARTS MANUFACTURING EXPERIENCE FOR GLOBAL CLIENTS

ALWAYS ON TIME DELIVER YOUR RAPID CNC PROTOTYPING PARTS

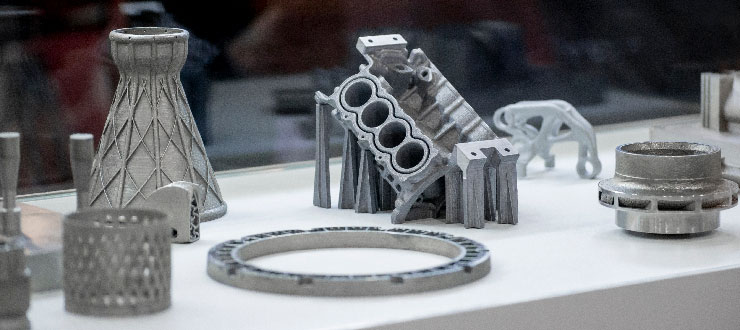

CNC prototyping & 3D printing & Prototyping tooling.

Aluminum, Zinc, Brass, Copper, Stainless steel, ABS, PC, POM, PP, PMMA, Nylon, etc.

We provide CNC prototyping parts with different kinds of surface finishings, including liquid painting, powder coating, sandblasting, anodizing, plating, etc.

CONSISTENT INVESTMENT AND UPGRADE OUR CNC PROTOTYPING EQUIPMENT

RECENT CNC PROTOTYPING PROJECTS

Sunrise Metal’s CNC prototyping parts are widely used in many industries globally, such as Automotive Engine or Gearbox, Marine Radar or Navigation Electronics, Medical Ultrasound Scanner, or Respiratory system, Automatic Valve or flow meters, etc.

- Stable And Creative Team

- Advanced Equipment

- Global Clients

- Premium Quality

- Fast Delivery

Our efficient and experienced engineering team is available to turn your design vision into a reality.

| No. | Name | Stroke | Q’ty |

| 1 | Mazak 7-axis turning&milling Machine | Ø658*1011MM | 1 |

| 2 | Mazak /Hass 5axis CNC machine | Ø850/Ø600 | 4 |

| 3 | 3-axis CNC machine center | 2000*1500MM | 1 |

| 4 | 4-axis CNC machine center | Ø250*800MM | 8 |

| 5 | 3-axis CNC machine center | 1000*600*600MM | 20 |

| 6 | CNC Lathes | Ø320*800/Ø610*1000MM | 2 |

| 7 | Sodick Wire cutting Machine | 400*400*200MM | 3 |

| 8 | EDM machine | 500*400*400MM | 2 |

| 9 | Surface grinder | 600*300*200MM | 1 |

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

Our commitment is to provide consistent, on-time delivery and enhance customers satisfaction at all stages.

GET A FREE CONSULTATION

Speak to an engineering consultant for your Rapid Prototyping parts to get customized suggestions and solutions based on your CAD and Step drawings.

CNC PROTOTYPING:

THE COMPLETE FAQ GUIDE

The CNC Prototyping service makes it possible to produce high-functioning prototypes of the finest quality. The entire process is digitally controlled and any metal can be subjected to CNC machining to produce industrial parts.

Sunrise makes parts based on customer ideas and specifications, with fast delivery.

- What is CNC Prototyping?

- Why use CNC Machining for rapid prototyping?

- What is the process of CNC prototyping? How does it work?

- What are the main stages involved in the CNC prototyping process?

- What are the additive and subtractive processes to produce components in CNC prototyping?

- What are the different CNC prototyping capabilities? (milling, turning, live tooling)

- What kind of components are made by rapid CNC prototyping?

- What are the different applications of CNC prototyping?

- How cost-effective is CNC prototyping? Is it expensive for small manufacturers?

- What is the difference between CNC prototyping and 3D printing?

- What are the advantages of CNC prototyping?

- Which materials can be prototyped by CNC machines at Sunrise?

- Are rapid CNC prototyping options available for both metals and plastics?

- What are the different types of CNC tools that are available for CNC prototyping?

- How can we overcome the disadvantages of CNC prototyping and machining?

- Which different machines are used by Sunrise for CNC prototyping?

- What are some of the surface finishing and post-processing services provided by Sunrise?

- How fast can CNC prototype orders be completed by Sunrise?

What is CNC Prototyping?

CNC prototyping is the manufacturing of fine, accurate, and fully-functioning prototypes using CNC machining methods. The prototype to be created is fabricated using a computer-controlled process.

The material is carved into the prototype by subtractive manufacturing using computer-controlled programs. Any metal can be made subject to Computer Numerical Controlled prototyping (CNC prototyping) in order to produce an efficient prototype. The CNC machined prototype is very close to the intended part or component in every manner.

CNC prototyping is a remarkable service for every industry due to its tendency to make parts from any machinable material. When compared with other prototyping methods, CNC machining provides better speed and greater efficiency. The cost-effective method takes precedence over the other prototyping methods.

Why use CNC Machining for rapid prototyping?

Rapid prototyping is the fast fabrication of a physical part and is used to test the efficiency and quality of different parts. The manufacturing of parts in larger quantities is based upon those prototypes. The most efficient method to do so is CNC machining.

CNC machining produces functional prototypes from the material of choice. It has certain advantages which makes it a viable technology to construct prototypes. CNC machining reduces consumed time and produces cost-effective prototypes that are mock-ups of an end result. The mock-ups created using CNC machining are precise and accurate. It has proved its worth in every industry whether its aviation or telecommunication.

What is the process of CNC prototyping? How does it work?

CNC prototyping is the process of creating working mockups of a product before it goes into the mass production phase. This is done to find out the faults and failures of the design with a real-time mockup that acts the same as the required product. Rapid prototyping when combined with CNC machines produces greater results.

Machine code is fed into the machine and a workpiece is placed in it. The machines start removing material from the initial block in order to generate a final part. The machine follows the code and considers the structural technicalities like wall thickness when doing so. The machine is limited by geometrical complexity, size, and accuracy.

What are the main stages involved in the CNC prototyping process?

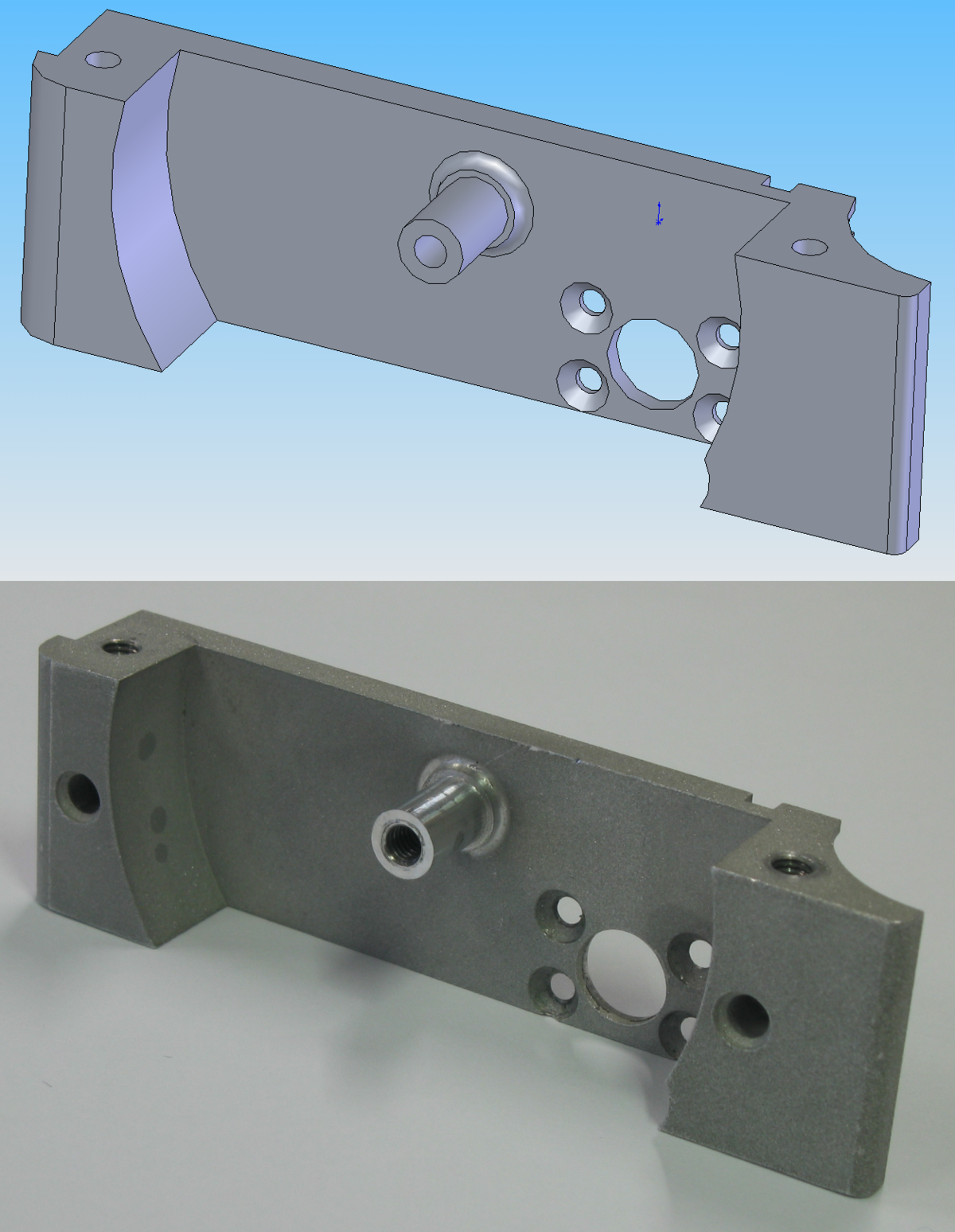

CNC prototyping is carried out using efficient CNC machines. The process follows different instructions to produce high-end results.

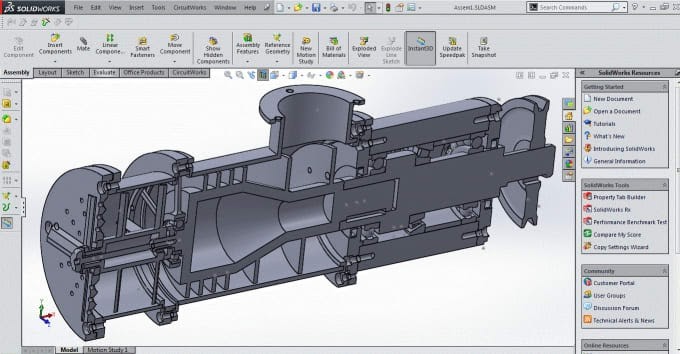

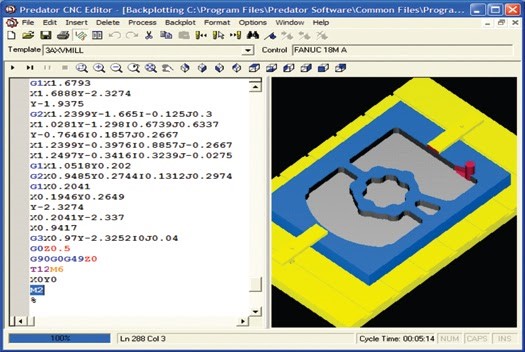

CAD model

A CAD model is designed with technical specifications. The model has limitations as it depends on the working ability of CNC machines. The model also depends upon the properties it is going to endure post-production. It is generated primarily using 2D or 3D technologies.

File conversion

The CAD design file is then converted into a CNC machine-understandable program. This program monitors the CNC machine and controls all of its functions. This code is fed to the CNC machine to start the process.

CNC machine

The CNC machine is then set up using the right set of tools in accordance with the design. The workpiece is also fixed in the machine and the machine is prepared for operation.

Executing the process

As the instructions are fed to the CNC machine, initiating the machine will prompt it to execute the instructions. The process is automated and the program dictates it throughout the process.

What are the additive and subtractive processes to produce components in CNC prototyping?

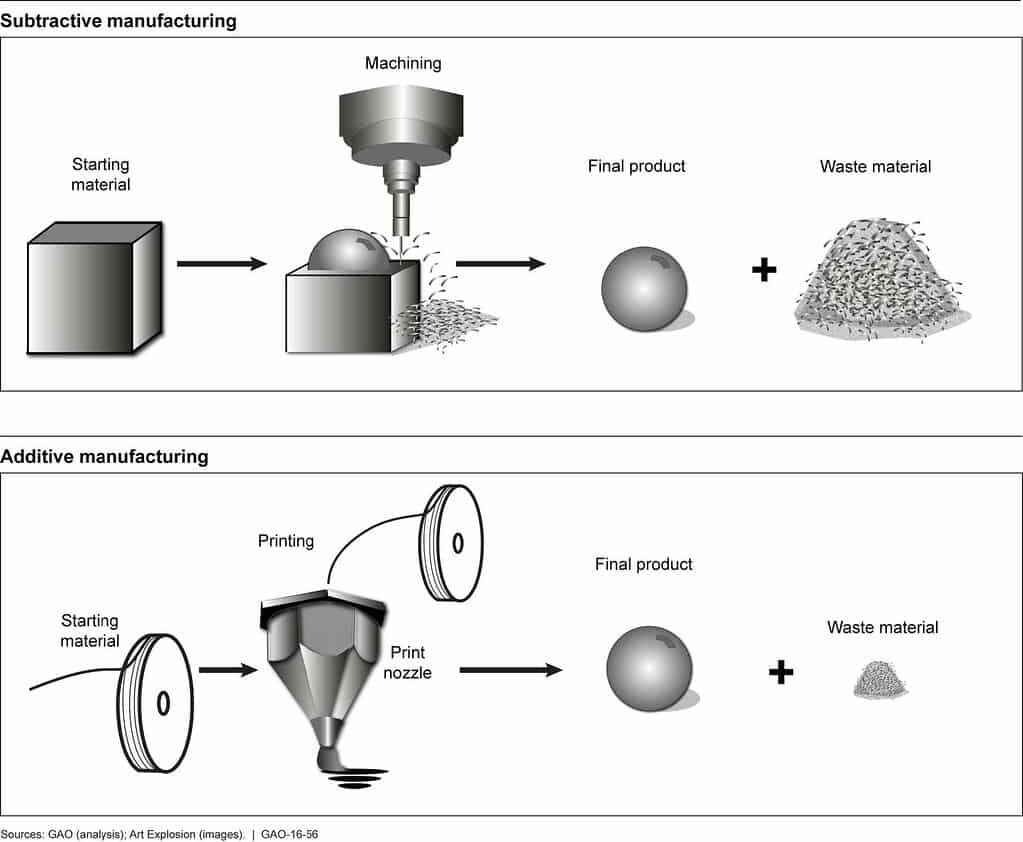

CNC prototyping makes use of different techniques in order to produce accurate mock-ups. To build the prototypes, processes applied are either subtractive or additive.

Additive processes

This process adds different layers of material into the design structure. The CAD design is followed by the machines and a sort of filling is done over the design. There is no waste material produced during additive manufacturing as the material is only placed where it is needed. The prototype created using additive manufacturing requires very little to no tooling. The material is melted and placed on the required places and then cooled down to achieve the end result.

Subtractive manufacturing

3D objects are created using this technique by subtracting the material from the workpiece using machines. A block is placed in the machine and the unnecessary part is removed from the block until the required appearance is achieved. Even a very thin piece of material can be subtracted to achieve a precise result.

What are the different CNC prototyping capabilities? (milling, turning, live tooling)

CNC prototyping produces accurate results by working on different techniques. The process gives a fast turnaround on the products. This process simulates the final product in order to make changes at this initial stage before producing it in large quantities. CNC prototyping is combined with different capabilities to produce these results:

CNC milling

Milling itself is a process that achieves a product using cutting technology on the workpiece that is placed in the machine. The CNC milling involves computer-controlled processes in order to do so.

CNC turning

CNC turning is a process that follows computer instructions to rotate a workpiece. The cutting tool moves in a linear fashion while the workpiece revolves inside the machine. Parts of the material are removed constantly. It is not the same as CNC milling which uses rotary cutters on the block to remove the material.

CNC live tooling

CNC live tooling is a computer-controlled process in which, unlike turning, the spindles and the cutting tools revolve around the block to remove the unnecessary material. The workpiece inside the machine is still at its place and the tool works its way around the material.

What kind of components are made by rapid CNC prototyping?

CNC prototyping uses subtractive machining processes and processes almost every material machinable. Efficient hardwares are created using this process. It is like sculpting but through the computer.

Rapid prototyping models are becoming increasingly popular in several industrial sectors. Applications include:

- Functional prototypes

- Patterns for casting

- Medical models

- Models for artwork

- Models for engineering analysis

What are the different applications of CNC prototyping?

CNC rapid prototyping has extensive applications. Parts created from CNC prototyping are being used in almost every industry.

Medical

The medical field has many applications of CNC prototyping. Researchers are working to apply this technique and revolutionize the field. Reconstructive surgery with rapid prototyping technology is being planned. This is almost the same as plastic surgery and is being tested using rapid CNC prototyping.

Other than this, cancerous brain tumor surgery is also said to be made operational using this technology. As the research is moving forward, rapid prototyping is moving towards transforming the medical field.

Automotive industry

Rapid CNC prototyping has extensive applications in the automotive industry. Cast metal engine block is created using rapid prototyping methods. Advanced driver control systems are being prototyped using this technology and are being tested to put into work.

Aerospace industry

The aerospace industry is growing its research to produce efficient solutions. Rapid CNC prototyping is being utilized for this. Air inlet housing for gas turbine engines is prototyped using this technology and is precise in nature. Flight-certified production castings are fabricated with this technology.

Manufacturing and tooling

Rapid CNC prototyping in this industry has wide applications be it direct or indirect soft tooling or hard tooling. The technology is applied to produce more efficient tools and is considered ideal for the processes. Manufacturing of all sorts makes use of this technology in either production in small volumes or prototypes that test the accuracy of the design.

How cost-effective is CNC prototyping? Is it expensive for small manufacturers?

CNC prototyping is considered to be an expensive procedure due to all the machinery being utilized and the automation it requires. But this process is cost-effective in the long term as it produces large quantities at a lesser cost and with less labor cost. The process does not need too much supervision as it is automated and provides better, more precise solutions.

The cost of any machining is reduced using this technology as the parts created using this technology are already in a near-exact shape.

The process is cost-effective for one-off and medium-sized businesses as well. Rapid CNC prototyping reduces the overall production cost of the parts as the machining time and complexity of the product reduces.

What is the difference between CNC prototyping and 3D printing?

CNC prototyping and 3D printing are both methods to produce solid objects. They differ in the techniques used to create those products.

Rapid CNC prototyping

Rapid CNC prototyping uses a subtractive manufacturing approach in order to obtain the required parts. The process is automated as a computer is attached to the machine which has an embedded software for the production. It is the go-to process for many manufacturers due to its potential of using different materials. Rapid CNC prototyping produces great dimensional accuracy. The process works better for the production of narrow pieces and tight tolerances.

3D printing

3D printing uses additive manufacturing techniques for the production of solid parts. Successive layers of material are laid upon each other until the object is created. It uses less material than that of subtractive manufacturing processes like CNC prototyping. The object is created using a digital file. The complex shapes are easily created using this process. It is finding its applications in a broader area.

What are the advantages of CNC prototyping?

CNC prototyping is being used on a large scale because of the advantages it provides. Here is a list of some of them:

Precision

CNC prototyping is precise and accurate to a thousandth of an inch. It is very little to no chance of error in the procedure. The process is used very frequently as it provides parts with dimensional accuracy.

Automation

The process provides round the clock services as it is completely automated. The production speed increases with this process. The products are obtained in a shorter time span than other comparable methods.

Mass production

The process is ideal for the mass production of required industrial parts. It does not need any further supervision after the data is fed into the machine. Even the scalability is increased using this method. Any changes required are fed into the machine and those changes are easily handled with this technique.

Identical parts

As the requirements are fed into the machine, the manufactured parts are completely identical to each other. This property cannot be achieved using other traditional methods. The process handles low tolerances very easily.

Which materials can be prototyped by CNC machines at Sunrise?

Sunrise Metal works on a broad range of material when it comes to CNC prototyping. Some of the materials being used at Sunrise are

- Aluminum: Sunrise uses aluminum to create CNC prototypes as it has desirable physical properties. Its strength plays a major role in its being a popular choice for prototyping. It offers excellent machinability.

- Zinc: The high strength and hardness of zinc are ideal for the production of prototypes. Sunrise uses these properties in order to provide more durable products. This material can also be recycled and reutilized.

- Brass: Brass is durable and provides higher resistance therefore Sunrise uses it in a wide variety of industries. This alloy is easiest to the machine and hence prioritized over others.

- Stainless Steel: Stainless steel is said to be self-repairing i-e it repairs itself after the machining is done. It has a protective layer over it which makes it suitable at Sunrise to produce prototypes. There is increasing use of stainless steel prototypes in different industries.

Are rapid CNC prototyping options available for both metals and plastics?

Rapid CNC prototyping is a viable option for both metals and plastics. The process produces prototypes for both using different subtractive technologies. Although it can prototype using plastics as well as metals, some materials are more difficult to work with than others.

Metal prototypes are handled without any complexities. The form of metals that CNC prototyping can work with are

- Brass

- Stainless Steel

- Aluminum

- Titanium

- Zinc

- Copper

There are different types of plastic materials that CNC prototyping can work with. A broad scope of materials is offered by Sunrise, including but not limited to the following:

- Derlin

- Nylon

- PTFE

- PEEK

- Acetal

- Torlon

The plastic prototypes are used in different industries. The automotive industry, household industry, consumer electronics industry, and many more use prototypes built from plastic.

What are the different types of CNC tools that are available for CNC prototyping?

CNC prototyping makes use of different tools as a setup to produce a precise part. It should work on 3 elements:

- Ideal cutting of the workpiece

- The spinning of the tool

- Proper advancement of the piece towards the end result.

To ensure these three elements, these tools are necessary

CNC system controls

The CNC machines should have operational controls that feed the design of the machinery. The controls should convert the design into codes and make the machine operational.

CNC cutting tools

CNC cutting tools are very important in defining the product’s capabilities. A poor cutting tool can restrict the quality of the product and can result in high maintenance and machining costs. These tools can guarantee superior quality, treat surface finish, and accurate parts.

CNC milling tools

These tools and turning tools are combined and a single set up is obtained. This set upturns the workpiece or the cutting tool and also mills the part. Different milling tools are placed in this setup e.g router tools, grinder tools, and tool setters.

How can we overcome the disadvantages of CNC prototyping and machining?

CNC prototyping and machining have some limitations that can be reduced in order to produce precise pieces.

Error

Although the process is completely automated, it can still produce errors. The human error can still be found as the machine is supervised by managers and engineers. The program can be wrongly fed and the controls can be used incorrectly. To overcome this, the training of the staff is necessary. A specialized team is required to work with the machines.

Initial Cost

The initial cost of the CNC prototyping process is relatively high. Production in larger quantities can make the process cost-effective. Once bought, the expensive tools and machinery give cost-efficient results which make up for the initial investment.

Which different machines are used by Sunrise for CNC prototyping?

Sunrise uses the most productive machinery to provide better results. CNC prototyping requires the use of the following equipment to do so:

Mazak 7-axis turning and milling machine

This machine provides a prototype built through working on 7 axes of the workpiece. This provides precise results as each axis is being considered during the working.

3 axis CNC machine center

This CNC machine center has a complete milling and lathe setup and works on the piece by moving about 3 axes simultaneously. The set up provides complete machining of the piece.

4 axis machine center

This setup provides the working on the piece by moving the tools about 4 axes. This is also a complete setup. Both 3 axis and 4 axis CNC machining centers are used depending upon the requirements of the end result.

What are some of the surface finishing and post-processing services provided by Sunrise?

Sunrise provides complete processing of the prototype that includes finishing and post-process services. The prototype is further subjected to different machining processes.

Tumbling

Sunrise uses this method to completely clean the metal part and to produce a de-flashed and descaled prototype. It brightens and hardens the surface of the part. It is similar to barreling which is also used to brighten the surface.

The prototype is subjected to an electrochemical process called anodizing and is made corrosion resistant. A natural oxide layer is produced over the part which increases the thickness of the part as well as makes it more decorative.

Powder coating

It is a dry finishing process that makes use of pigment in the form of finely ground particles. These are sprayed on to the surface of electrically grounded parts as they adhere until melted and fused into a uniform coating.

Additional surface finishes

Sunrise uses other finishing techniques as well as required. These finishing processes make the products more functional and aesthetic, namely:

- Liquid painting

- Plating

- Printing

- Polishing

- Sandblasting

How fast can CNC prototype orders be completed by Sunrise?

Sunrise has a fundamental promise of producing rapid CNC prototypes that helps the companies speed up the process of marketing. Quick product delivery is provided with a quick production arrangement.

To stay ahead of the competition and to make sure only the best outcomes are achieved, Sunrise offers:

- Rapid prototyping

- Rapid tooling

- Rapid production

- Rapid delivery

For a volume of less than or equal to 200 pieces, Sunrise produces the result in 1-2 weeks. This includes the manufacturing and the finishing of parts. This saves 50% of the client’s time and results in faster project completion.