Your Premium Prototype Manufacturing Supplier in China

Sunrise Metal prioritizes customer design and ideations and customizes orders for many of its customers. In doing so they Sunrise Metal displays integrity and commitment to providing the best rapid prototyping solutions which are second to none. Advanced quality equipment, including X-ray detectors, spectrum meters, and Carl ZEISS CM, are all part of the workflow at all facilities. A strong quality control system ensures that we are in line with international standards and go to every length to produce the finest product.

Our advanced Rapid Prototyping facilities help in reducing the standard lead time by up to fifty percent. The customer gets high-quality prototypes while keeping the production time minimum. This helps in boosting efficiency and bringing down costs during the product development process. Cost-saving suggestions, optimization of customer models, and technological advancement are some of the key factors that make us stand out as industry leaders.

Customers can also save a lot of time by choosing Sunrise Metal as their rapid prototyping partner since we have all the rapid prototyping technologies in one place. By providing 3D printing, CNC Machining, Rapid Tooling, and several surface finishes at one place, Sunrise Metal helps in getting rid of the hassle of switching between suppliers.

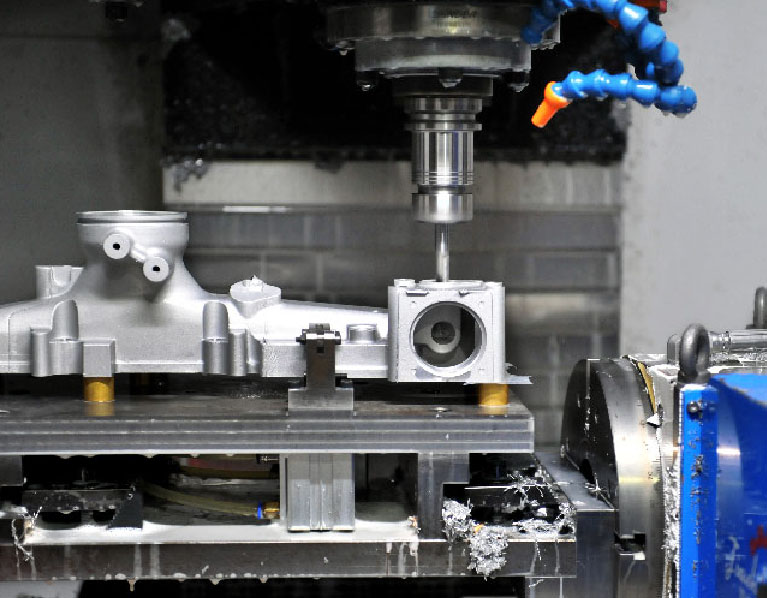

Your Perfect Prototyping Parts Coming From Sunrise High-end Machining Equipment

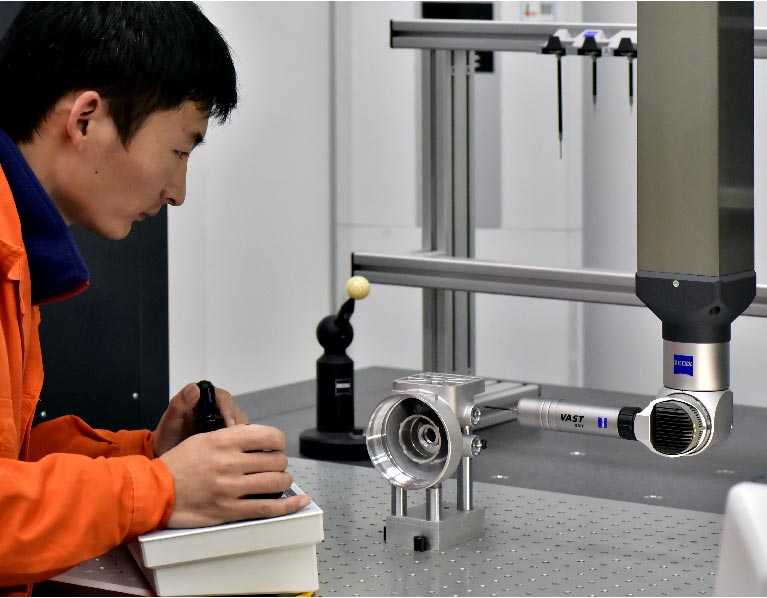

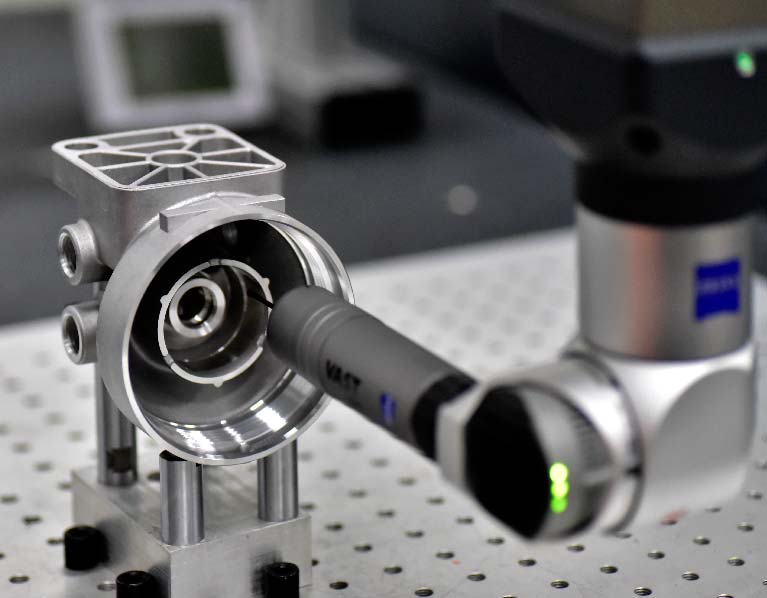

Helping Your Projects Succeed With Sunrise Strict Quality Control Capability

Sunrise Metal invested many Modern measuring instruments, such as Carl Zeiss CMM, X-ray Detector, and Spectrometer and Cleanliness testing Lab, etc. To assure you of good quality with your parts, we will continually invest in Inspection instruments and training on our employees.

Quality is the top priority of our work. To achieve our promise on quality to our customers, we introduced the third parties to help improve our quality control Management system. We have built a very effective QC management system under the instruction of ISO, we are ISO9001, and IATF 16949 certified CNC machining manufacturer.

Sunrise has very stable and rich-experienced QC team. They are not only good at making SIP per Control Plan–CP and flow charts–FC, but also very familiar with our production processes. So they know When and Where the defects will happen, and how to avoid them in advance. To assure you of good quality with your parts, we will continually invest in Inspection instruments and training on our employees.

10000+ Prototyping Parts Manufacturing Experience From 500+ Global Clients

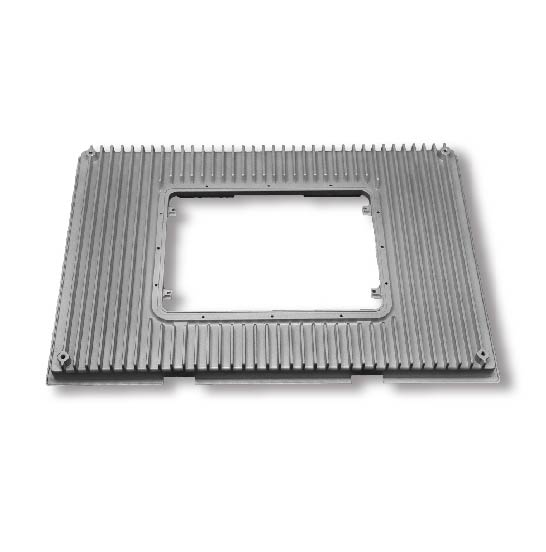

Various Surface Finishing For Prototyping Manufacturing Parts

Sunrise Metal tries all our effort to offer a 1-stop solution service to your prototype parts.

Wide range of material: Al6061, Al6063, Al5052, Stainless Steel, Copper, and many kinds of plastic, etc.

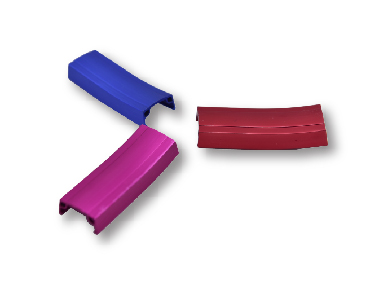

Second surface finishing source: Anodizing, Chromate, Powder coating, wet painting, E-coating, Plating, Silk printing, etc.

All our parts are meet ROHS and REACH requirements.

- Advanced Prototyping Machining Equipment

- Premium Quality Measuring Equipment

| No. | Name | Stroke | Q’ty |

| 1 | Mazak 7-axis turning&milling Machine | Ø658*1011MM | 1 |

| 2 | Mazak /Hass 5axis CNC machine | Ø850/Ø600 | 4 |

| 3 | 3-axis CNC machine center | 2000*1500MM | 1 |

| 4 | 4-axis CNC machine center | Ø250*800MM | 8 |

| 5 | 3-axis CNC machine center | 1000*600*600MM | 20 |

| 6 | CNC Lathes | Ø320*800/Ø610*1000MM | 2 |

| 7 | Sodick Wire cutting Machine | 400*400*200MM | 3 |

| 8 | EDM machine | 500*400*400MM | 2 |

| 9 | Surface grinder | 600*300*200MM | 1 |

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

Get A Free Consultation

Skillful engineering consultants for aluminum CNC precision machining parts. Specialized and project relevant advice will be based on your CAD and Step drawings.

Here is just a small part but an important way that we’re serving you on CNC precision machining projects.

Sunrise Metal can offer full chain service if you have any needs for aluminum die casting. Looking learn more about aluminum die casting.

CNC PRECISION MACHINING- THE COMPLETE FAQ GUIDE

Sunrise Metal values customer convenience and satisfaction over everything else. That’s why we have presented this guide for you. We are hopeful that you will find most of your queries about prototyping manufacturing and our company in this guide. If you still have any other questions in your mind, don’t hesitate to contact our customer support team for help.

- What is prototype manufacturing?

- Why is aluminum prototype manufacturing preferred over other types of metals?

- What are some of the most used prototype manufacturing methods?

- What are the benefits of precision prototyping manufacturing?

- How does rapid prototyping manufacturing make the production process more efficient?

- What are some rapid prototyping techniques?

- When is prototyping manufacturing necessary?

- What is the manufacturing process to make a good prototype?

- What kind of industrial parts are produced with rapid prototyping technology?

- What is additive manufacturing 3d printing for prototyping and manufacturing?

- What prototyping and manufacturing solutions are offered by Sunrise?

- How can clients benefit from low volume manufacturing capabilities of Sunrise?

- As a leading China prototyping manufacturing company, how does Sunrise ensure customer satisfaction at all levels?

What is prototype manufacturing?

A prototype is the first version of any product to be manufactured. It is a sample that evaluates a new design. Prototype manufacturing is the process of building prototypes that are used to test a concept or a process. It helps in design verification while providing information about design flaws before it goes into production.

The cost of discovering errors after the product is far into the development phase is very high. The delay in the delivery of the product can also result in additional costs. The prototype manufacturing process is beneficial in many forms. This production makes it possible to develop the tools required in some of the most complex manufacturing processes.

Why is aluminum prototype manufacturing preferred over other types of metals?

Manufacturing prototypes using aluminum is most preferred in the industry today. Aluminum bar stock is used mostly for this purpose. This is due to the several advantages that aluminum provides, listed as follows:

Net shape

Aluminum is required in the prototypes to achieve a net shape. This quality allows the generation of less waste. It maintains a competitive advantage in the market as an almost perfect shape provides quality.

Secondary operations

When the near net shape is achieved, there’s no need to have secondary operations on the aluminum prototype. Very less machining is required in order to produce the end result. Aluminum prototypes don’t require the tooling in order to generate a better result.

Freedom of shape

Aluminum in the manufacturing of prototypes gives you the freedom of creating any shape. Aluminum is easily deformed and can hence provide any required shape. Complex, intricate patterns, and various sizes can be obtained using the technique.

What are some of the most used prototype manufacturing methods?

To manufacture prototypes, certain manufacturing methods are used. The most advanced method used for the purpose is Rapid Prototyping. It is different than other traditional methods and provides an array of advantages.

Rapid Prototyping

Rapid prototyping is the method of fast fabrication of tools using 3D technologies and certain advanced techniques. The process makes use of additive manufacturing. The prototypes obtained using this technology are high fidelity prototype meaning it closely matches the design.

The process has its advantages

- Rapid prototyping increases the speed of the process and makes the projects launch faster in the market.

- It costs less than other methods and is more reliable making the future maintenance costs decrease.

- The process provides a large range of designs including small-sized, detailed parts.

Traditional Prototyping methods

These prototyping methods include the die-casting method from traditional machinery. These methods can take days in the prototyping and produce low-fidelity prototypes, and the final product is not close to the proposed design. The cost of these methods is also higher than that of rapid prototyping. These methods are in fact more suitable for heavy machinery and tools.

What are the benefits of precision prototyping manufacturing?

Precision prototyping is the process of manufacturing where precision is highly prioritized. This prototyping process creates complete functioning prototypes and the finest quality, accurate parts. It provides many benefits to the manufacturing industry. It includes processes like CNC machining, Stereolithography, Selective Laser Sintering, Fused Deposition Modelling, and many others. Some of the benefits that these processes provide are

- Near net shapes are obtained using precision prototyping.

- Faster prototyping saves weeks not days.

- A huge decrease in the long-term costs of prototyping.

- Less to no machining required for precision prototypes.

- A large range of designs is obtained using the process.

- Single part testing is made easy with precision prototyping.

- Additional designs are easily explored using this prototyping

- A variety of material or almost any material can be used to prototype with this process.

- Depending upon the material, these prototypes can stand high temperatures and pressures.

- The risk of creating a faulty batch of tools is reduced using a precision prototype manufacturing process.

How does rapid prototyping manufacturing make the production process more efficient?

Rapid Production is a more advanced method of prototyping that provides certain benefits to the prototyping industry. The process gives fast fabrication of the tools required in the industry. Rapid Prototyping produces efficient results from design to production in many ways.

Design

The process of rapid prototyping provides efficient designs using computer-aided programs. The designs are a digital representation of the product required. Before producing a prototype, these designs can be altered virtually. This phase covers every requirement of the product to be manufactured.

Production

The production phase of Rapid prototyping is fast and lessens the work as compared to the other processes. The production is carried out using computer-controlled processes. There are certain methods to do so and each method provides the same efficiency as the other. The prototype produced is near to the actual product and gives all the specifications of the required product. The design of the product can be changed after the prototype is obtained.

Machining

The prototypes created using Rapid Prototyping require very little to no machining. This makes the process cost-effective as well as efficient. Machining only polishes the product to be more structured and hence increases its efficiency.

What are some rapid prototyping techniques?

Rapid Prototyping is carried using certain techniques. These techniques are helpful in producing efficient and cost-effective results.

- Stereolithography (SLA)

It is an additive manufacturing process that makes use of the ultraviolet rays. These rays focus on photopolymer resin that is sensitive to the UV rays. The liquid of this material is solidified on the required design drop by drop and a prototype is created.

- Selective Laser Sintering (SLS)

This process uses powder to form the prototype. The layers of the powder are sintered according to the design. The powder bed is formed on the design but the surface of his prototype isn’t smooth. This process requires finishing to complete the prototype.

- Selective Laser Melting (SLM)

This process of rapid prototyping also uses powder in the formation of prototypes. The powder is first melted and is then placed on the design using a laser beam. This process is widely used in aerospace, automotive, defense, and medical industries.

- Digital Light Processing (DLP)

This process is similar to SLA but requires a more conventional light source than ultraviolet rays. The resins are melted and used for production. DLP requires machining and other support structures.

Other rapid prototyping processes include Laminated Object Manufacturing (LOM) or Sheet Lamination, Fused Deposition Modelling (FDM) or Material Jetting, Binder jetting, and many more.

When is prototyping manufacturing necessary?

Prototype manufacturing is the process of developing prototypes of tools or products before they go into the production phase. This is done to make the process foolproof. The process is carried out to

- Get user acceptance

Prototyping allows the customer to get a preview of the product. This gives early feedback on the product and lets the designers implement the changes in the early stages. Late realization of the technical issues can increase significantly with time.

- Define requirements, constraints, and limitations

The prototype manufacturing gives you a complete discovery of requirements for the product. This simulates the functionality that the product is going to achieve and hence gives a solution for all the constraints and limitations that are shown in the earlier stage. The side effects of the tools are discovered at this point.

- Estimate cost, time and complexities

The prototype manufacturing can help estimate the costs for the manufacturing of the product. It also gives an estimate of the time that it is going to take during the production of the part or any complexities that the process can face.

What is the manufacturing process to make a good prototype?

The process of manufacturing a good prototype follows these steps

- Understanding the technology and the problems that require the solution before building a prototype.

- Understanding the requirements of building that prototype.

- Create a design after the required research using the most advanced technologies to avoid any mistakes.

- Rework on the design until it is perfect virtually.

- Start the development phase with the technologies and processes most suitable for it. This process should be carried out after the complexities have been solved.

- Evaluate the prototype that is manufactured. Record all the flaws and measure them both quantitively as well as quantitatively.

- Most of the prototypes are ready to go into the production phase but some are not. These prototypes are revised and are again sent for enhancement.

- Repeat the steps above.

What kind of industrial parts are produced with rapid prototyping technology?

Rapid Prototyping is used to develop products for various industries. It is known to help almost every industry that requires metal tool manufacturing.

- Marine

Rapid prototyping is said to be a powerful tool for the marine industry. It helps in making prototypes for the tools to be used in marine environments and can be tested before they are implemented. This gives know-how of the functionalities of the tools to be used in water.

- Aerospace

Rapid prototyping can help build prototypes of the tools used in the aerospace industry. These tools are used in the construction of airplanes and hence are quite costly. To avoid making changes in the late stages of production, rapid prototyping is utilized.

- Automotive

The automotive industry needs tools that are resistant to corrosion and are highly precise. The parts used in automotive are now required to be lightweight. To fulfill all the requirements of the industry, rapid prototyping helps in the stages of testing requirement specifications.

- Medical

Medical instruments are used for highly sensitive purposes. Therefore, they are required to be free of defects. To ensure this, rapid prototyping is used in the early stages of design to provide a compact solution to the needs.

- Telecom

The Telecom industry is responsible for communication all around the world. The tools and products used have to work properly in order to provide seamless connectivity. Rapid prototyping helps in providing exactly that.

What is additive manufacturing 3d printing for prototyping and manufacturing?

Rapid prototyping uses additive manufacturing for the production of prototypes.

Additive manufacturing is a technique where the material is added to the design in order to form a product. The process mostly uses 3D processes and is precise. With the help of this process, hard objects are deposited upon the required shape layer by layer. The results produced have highly accurate geometric shapes.

3D printing is a process that uses additive manufacturing techniques for the production of the prototype. A 3-dimensional object is produced using CAD and CAM software. A digital file is created and the design is carried out using different tools and processes required to print them. This can be carried out using melted metal or whichever material is required for the product.

What prototyping and manufacturing solutions are offered by Sunrise?

Sunrise is a leading manufacturer of die-cast products, tools, and prototypes. It is a one-stop-shop from design to finishing. For this purpose, certain prototype and manufacturing solutions are offered by Sunrise.

Aluminum die-cast and tooling

Sunrise offers competent solutions for aluminum die casting and die cast tooling. These solutions provide reliable die cast products for every industry.

Rapid Prototyping

Sunrise offers rapid prototyping services that help to make the products free of defects in the initial phases. Sunrise’s prototyping services allow the customer to realize the requirements and constraints before it goes into production.

Sunrise also offers reliable CNC machining services and provides technical proposals and cost-saving suggestions for the customers. CNC machining helps the customers get high advanced Inspection Instruments.

Sunrise metals also provide machining services for all the products obtained from the different processes. These services are used to give the products a surface finish.

How can clients benefit from low volume manufacturing capabilities of Sunrise?

The die casting process is considered to be beneficial when the requirement is high volume products. It is said to be cost-effective and efficient when the product is required in large volumes.

Sunrise’s advanced technologies and processes even allow the production of low volume. The clients can benefit from this service for the production of pieces as low as one. The fast production system and rapid delivery can help in fast marketing time as well.

As a leading China prototyping manufacturing company, how does Sunrise ensure customer satisfaction at all levels?

Sunrise is an ISO 9001 and IATF 16949 certified company. These certifications are provided after the complete training of the employees to provide customer satisfaction. Sunrise is providing optimum solutions and is adding value to the work by

- Providing a commitment to the customers.

- Meeting customers and other stakeholder needs within statutory and regulatory requirements.

- Consistently improving the quality of products and services.

- Fulfilling the need of the customers by adding value to the services.