ALUMINUM PROTOTYPE MANUFACTURER IN CHINA-SUNRISE METAL

The experienced engineers, premium prototyping capabilities, and state-of-the-art techniques make us become one of the leading aluminum prototype manufacturers in China. Our complete solution allows us to provide you with our rapid prototyping service which helps in faster turnaround time.

Our customers can benefit from our rapid prototyping & die casting processes. Some of our prototyping needs to make use of the CNC machining rapid prototyping which is more precise. And others may need our rapid tooling service that the parts are cast from rapid tooling.

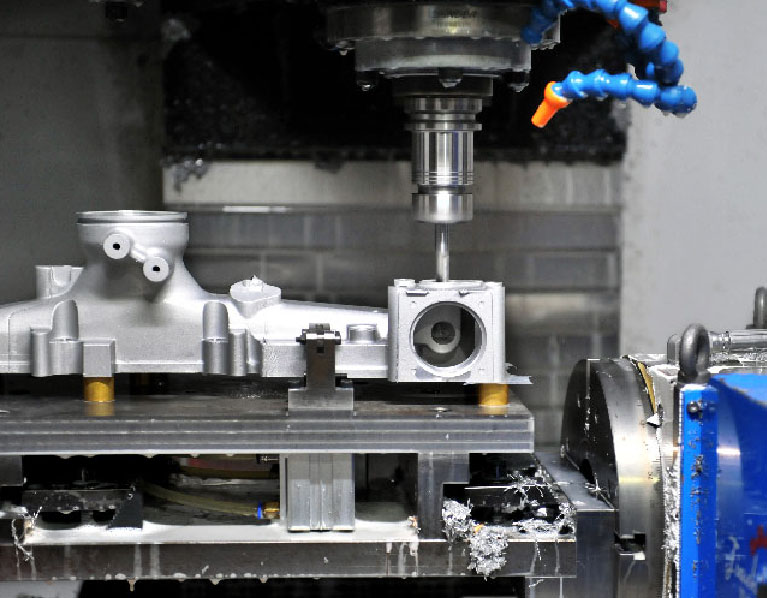

PERFECT PROTOTYPES MADE POSSIBLE WITH SUNRISE HIGH PRECISION MANUFACTURING EQUIPMENT

TRUST SUNRISE RAPID PROTOTYPING CAPABILITY

The process of aluminum prototyping at Sunrise is mainly controlled by CNC software to reduce human error. Your product requirements are fed into the software to achieve precise results.

- CAD software

- CAM software

- Simulation Software

- Machining Software

We use rapid prototyping technology to help save half time to market for our clients. Our one-stop service also can bring customers reasonable cost, good quality, and timely delivery.

1000+ ALUMINUM PROTOTYPES MANUFACTURING EXPERIENCE FROM 500+GLOBAL CLIENTS

PRECISE ALUMINUM PROTOTYPE SUPPLIER IN CHINA USING ADVANCED SUBTRACTIVE PROCESSES

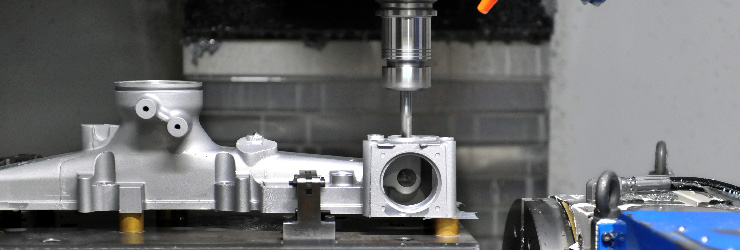

Sunrise Metals’ dedicated die casting facilities include our machining workshops that help in manufacturing aluminum prototypes. Your accurate prototypes are produced by our precise CNC machines.

Our CNC machining centers have auto tool changing ability: Fanuc CNC machining centers, Hass CNC machining centers, CNC grinding machines, CNC lathing, drilling machines, and 7 axis CNC machines.

- Aluminum Prototyping Advanced Equipment

- Premium Quality

- Fast Delivery

| No. | Name | Stroke | Q’ty |

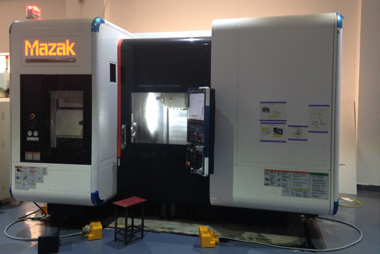

| 1 | Mazak 7-axis turning&milling Machine | Ø658*1011MM | 1 |

| 2 | Mazak /Hass 5axis CNC machine | Ø850/Ø600 | 4 |

| 3 | 3-axis CNC machine center | 2000*1500MM | 1 |

| 4 | 4-axis CNC machine center | Ø250*800MM | 8 |

| 5 | 3-axis CNC machine center | 1000*600*600MM | 20 |

| 6 | CNC Lathes | Ø320*800/Ø610*1000MM | 2 |

| 7 | Sodick Wire cutting Machine | 400*400*200MM | 3 |

| 8 | EDM machine | 500*400*400MM | 2 |

| 9 | Surface grinder | 600*300*200MM | 1 |

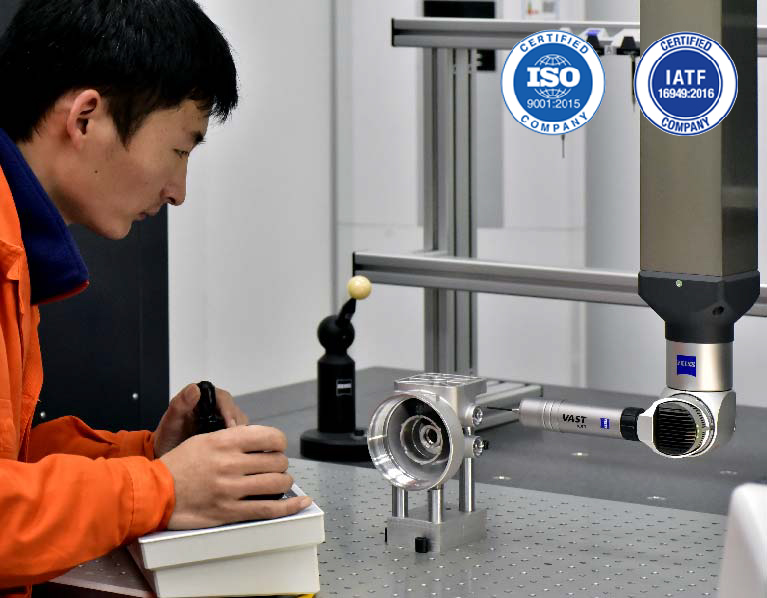

| No. | Name | Brand | Q’ty |

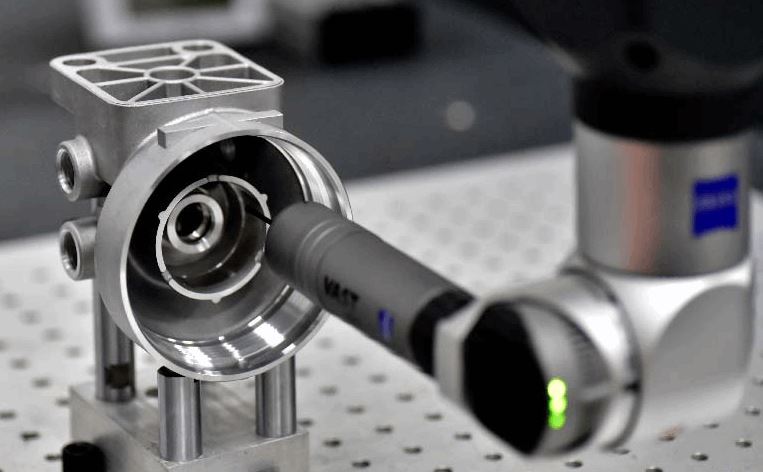

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

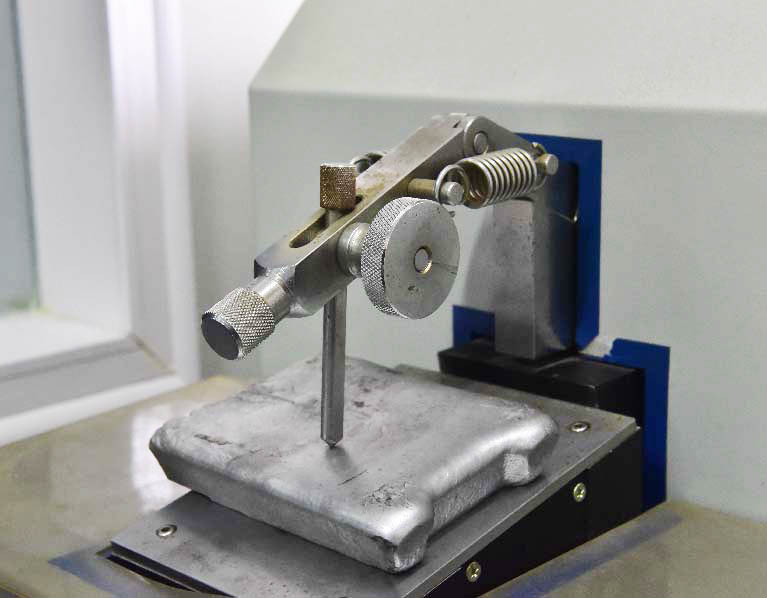

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

Our commitment is to provide consistent, on-time delivery and enhance customers satisfaction at all stages.

GET FREE CONSULTATION

Speak to an engineering consultant for your Rapid Prototyping parts to get customized suggestions and solutions based on your CAD and Step drawings.

ALUMINUM PROTOTYPE MANUFACTURER:

THE ULTIMATE FAQ GUIDE

This article is a complete Frequently Asked Questions (FAQ) guide for aluminum prototype manufacturers. The goal of this guide is to provide you with answers to all the questions you have about aluminum prototype manufacturers

It will guide you to make the best decision in choosing a reliable manufacturer for the success of your business.

- What is an aluminum prototype manufacturing?

- How do aluminum prototyping suppliers create prototypes?

- What techniques are used by aluminum prototype manufacturers in China?

- How to ensure the aluminum prototyping process efficient and cost-effective?

- Do you cater to low-volume manufacturing?

- Can you make 3D prototyping suitable for mass production?

- How are aluminum prototypes used in creating industrial components?

- What are the applications of 3D aluminum China prototype manufacturing?

- What 3D printing processes are used by prototype manufacturers?

- What prototyping advantages are offered by aluminum prototype manufacturers to industrial users?

- What are the features of aluminum alloy rapid prototypes that make them so popular?

- What characteristics of an aluminum prototype should a manufacturer focus on during production?

- What materials/alloys other than aluminum can be used by prototype manufacturers in China?

- Which software is used by aluminum prototype manufacturers for the process of 3D prototyping?

- Is aluminum prototype manufacturing an additive process?

- Which subtractive prototype manufacturing processes are used by Sunrise as an aluminum prototype manufacturer in China?

- Does prototyping manufacturing require expensive tooling and specialist equipment?

- What kind of tooling is used by Sunrise Metal for aluminum prototype manufacturing?

- How is rapid tooling made possible by aluminum prototyping manufacturers?

- Which CNC machining is used by Sunrise that makes it a high-tech, leading aluminum prototype manufacturer in China?

- How do CNC operators at Sunrise produce complex aluminum prototype parts?

- Which CAM software is the most commonly used by rapid prototype manufacturers?

- What equipment does Sunrise metal use for quality inspection?

- How does Sunrise Metal control the quality of prototype parts?

- What machines does Sunrise Metal use for aluminum CNC prototypes?

- What machines does Sunrise Metal use for aluminum die casting prototyping Tooling?

What is Aluminum Prototype Manufacturing?

Aluminum prototype manufacturing is the process of rapid manufacturing from the block of aluminum. This process involves different techniques and different machinery to come up with the best design possible.

Manufacturers and designers try to come up with their end product in the least time possible. This is done to save time and cost. Therefore, a sample is made, which is very close to the original product.

Aluminum products are very much in demand and have many applications in different industries. Before producing the high-budget products, aluminum prototype manufacturers build prototypes that help polish up the design.

The techniques involved in the process are:

Additive prototype manufacturing

The aluminum prototype manufacturers use additive manufacturing techniques to reduce waste material. This involves the process of laser sintering, and other 3D printing processes to build aluminum prototypes. The method creates the prototype from the ground up. Aluminum layers that are either in the form of melted metal or resins are deposited over the design to get the complete prototype.

Subtractive Prototype Manufacturing

Aluminum prototype manufacturers also use another technique to build aluminum prototypes called subtractive manufacturing. This is done by removing the particles of aluminum from the aluminum block. The process is repeated until the prototype in the design is achieved. CNC machining is mostly used to generate such prototypes and involves CNC milling, CNC cutting, CNC turning.

How do Aluminum Prototyping Suppliers Create Prototypes?

Aluminum prototype manufacturers create prototypes using several processes. Some of the most common approaches are:

- Machining

Machining aluminum is the most common method used by aluminum prototype companies. One of the most popular forms of machining for prototypes is CNC machining. The process involves the following steps for the production:

- Designing the prototype and making its digital file eg CAD

- Converting the CAD file into CNC code

- Employing the code to the CNC machine

- Choosing the appropriate tools for the design

- Running the final code.

The CNC machinery runs automatically and produces the prototype in very little time. The built prototype is precise and very close to the required part.

- Rapid Tooling

Rapid tooling is one of the main prototyping techniques being used in China. Rapid tooling molds prepare prototypes and parts with accurate results. Before full-scale production starts, the rapid-tooled mold creates only a few hundred parts.

The rapid tooling process helps to streamline the manufacturing process so that it produces only precise designs according to customer demand. Rapid tooling has several benefits:

- Test material before production

- Test full range of design

- Test full production process

- Reduce production risk

- Increases speed to market

- Printing

The process of 3D printing is also a popular choice among aluminum prototype manufacturers. It is relatively affordable and time-effective. The process involves additive manufacturing to build prototypes. 3D printing also involves digital design files just like CNC manufacturing. The process gives geometrical flexibility and can build complex aluminum prototypes in a very short time. The internal sections of the aluminum prototype are also manufactured with complete detail since the prototype is being produced layer by layer.

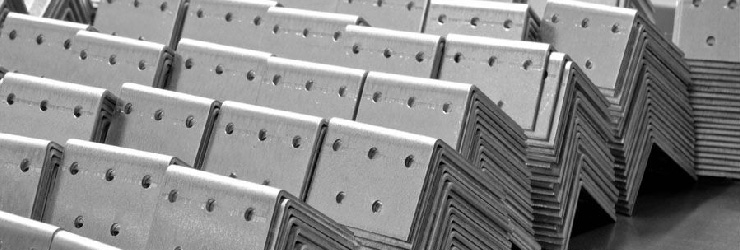

- Sheet Metal Fabrication

This process involves cutting, deformation, and assembly of aluminum sheets. Aluminum prototype manufacturers make the functional prototypes or the prototypes of functional parts from these sheets.

Laser cutting, punching, bending, spinning, and welding are used to turn the layers of aluminum sheets into aluminum prototypes. The prototypes formed from sheet metal fabrication are strong and durable. They are manufactured using a mix of different sheet metal fabrication processes. For example, a laser cutter, brake, and punching machine are used to develop the right-angle bracket prototype.

- Casting

This process requires expensive machinery and more expertise. It involves pouring melted aluminum liquid into a mold and cooling it down to achieve the prototype. The tooling processes, however, make the process more efficient and less costly. Some special ways like CNC machining and 3D printing are employed in the process to do so.

- Extrusion

This process is not typically used for prototyping. The aluminum prototype manufactures use it for the production of the original part rather than manufacturing prototypes. This is because manufacturing prototypes from this process is time-taking as well as more expensive. When it comes to aluminum, it can be used to manufacture simple prototypes like metal bars, brackets, and joints.

What Techniques are Used by Aluminum Prototype Companies in China?

Aluminum prototype companies use different processes for the manufacturing of prototypes in China. The prototypes are built using CNC machining, sheet metal fabrication, 3D printing, extrusion, and many other processes. Some of the techniques used in these processes are:

Selective Laser Sintering (SLS)

It is an additive manufacturing process. The aluminum prototype companies in China manufacture 3D parts with complex geometries using this technique. It is an additive manufacturing process. A wide range of aluminum prototypes is possible with SLS.

The technique uses a laser to sinter powdered aluminum aiming the laser at points in space. The aluminum powder is bound together to create a solid structure. A base plate in the SLS machine receives the successive layers of aluminum powder to create the 3D printed prototype. The choice of finishing and different turnaround options are available to suit most of the requirements of the prototype.

Stereolithography(SLA)

The aluminum prototype manufacturers in China use a photochemical process to manufacture 3D aluminum prototypes called stereolithography (SLA). It is an additive manufacturing process that uses computer-aided software for the production of prototypes.

The prototypes manufactured using this process are of good quality and smooth surface finish. SLA produces aluminum prototypes with high accuracy and shows excellent optical clarity. It helps manufacturers in China to speed up the process of production and start with the marketing of the product.

CNC machining

The aluminum prototype companies use CNC machining ranging from 3 axes to 7 axes for the production of aluminum prototypes. The machines are automatically controlled with a computer and are efficient.

This method of machining makes it possible to cater to low volume orders of prototypes. The technique is completed by methods of CNC milling, CNC lathing, CNC cutting, and other tooling processes. It uses 3D design and simulation techniques to manufacture aluminum prototype in a more precise and accurate manner.

Prototype Tooling

A different die-cast prototype tooling material is required in the process of prototype tooling. The aluminum prototype manufacturers in China use hard tools made by mold steel for the production as they can be easily cut into prototypes.

This results in cost-effective and efficient solutions in order to get a precise overview of your design and ideas. It allows quick turnarounds of the prototype manufacturing and hence is the preferred choice for many prototype manufacturers.

How to Ensure the Aluminum Prototype Process Efficient and Cost-effective?

Different techniques and processes are used by aluminum prototype manufacturers to get efficient prototypes. The manufacturers in China make use of the following factors to ensure that the process is cost-effective:

Complex geometry

The prototypes with complex geometries are difficult to achieve with traditional methods. The aluminum prototype manufacturers in China find the most suitable and advanced method to achieve precise parts.

Processes like stereolithography, fused deposition modeling, and selective laser sintering help in achieving complex geometries. These additive manufacturing processes are more detailed as compared to subtractive manufacturing.

Material

Aluminum prototype manufacturers have to consider the material before choosing the process that will be efficient as well as affordable. For aluminum prototype manufacturing, there is a large range of production processes that can achieve this. For example, CNC machining is just as effective as SLA. Each material has a different suitable process or prototype manufacturing.

Finishing Techniques

The aluminum prototype manufacturers in China mostly choose the process that does not require any tooling. The prototype created should be as near to the required part as it can be. Each prototype has different requirements e.g grinding, surface polishing, coating, etc to achieve its final form. Processes like die casting and extrusion can also be used for the manufacturing of aluminum prototypes but are avoided by most manufacturers in China as they require all of these tooling processes.

Waste Material

The process with more waste generation leads to more costs. The aluminum prototype manufacturers in China try to choose the processes that have less waste material. Additive manufacturing processes are some of such examples that make the prototype manufacturing cost-effective and efficient.

Do You Cater to Low-volume Manufacturing?

Every prototype manufacturer uses different prototyping techniques than others according to their own priorities. Low-volume manufacturing is not achievable by every process. The traditional processes require the production of at least 1000 parts at a time. This used to result in higher costs and longer times for production.

The prototypes made from such conventional methods require additional tooling. The changes required in the design of the prototypes are also costly. For example, after the initial run, it is required to print the name of the client on the prototype. The price often doubles and the time of production increases by weeks. The first 1000 parts, which is a lot, will also not have the same design.

In the case of processes that enable low-volume manufacturing, the minimum amount of prototypes to be manufactured is sometimes as low as a single part. The prototype manufacturers that can cater to low-volume projects too use the following techniques among many:

- 3D printing

The 3D printing process is a fast and reliable process to achieve a small number of prototypes. The process is flexible and there is no additional cost for the design change. The whole procedure goes at the same speed as it was going before the change. The prototype repeatability is also one of the main factors that help in low-volume production. The duplicates are made at the same rate with the same amount of material. Each part is the exact copy of the other as no human error is involved in the process.

- CNC machining

Some aluminum prototype manufacturers in China also use CNC machining techniques for the production of low-volume prototypes. The process is controlled by a computer and forms precise parts.

It is a subtractive manufacturing process and carves the prototype out of the aluminum block. This process is also flexible to any design changes and can produce as low as 1 prototype.

Can prototype manufacturers make 3D prototyping suitable for mass production?

For a long time, 3D prototyping was thought suitable for only low-volume projects but that isn’t the case anymore. The most developed and advanced aluminum prototype manufacturers in China have made 3D prototyping suitable for mass production as well. The technique has brought infinite design possibilities to the table. Today, it is also being used for mass production but with limitations. It all depends upon the requirements.

Complex Parts

If the complex parts are required in a large volume, the traditional prototype manufacturing techniques might not be that cost-effective. This is due to the fact that 3D printing can produce more precise and accurate parts. The aluminum prototype manufacturers might be able to make these prototypes in a large volume but in a very short time than 3D printing but they won’t be as efficient as the ones made with 3D printing. The part efficiency makes up for productivity in terms of time in this case.

Simple parts

If the required part is, let’s say, a simple nail, the requirements for the production are not going to be that complex. No additional tooling will be required and hence, the traditional techniques will work better than 3D printing. The aluminum prototype manufacturer will take less time and will be able to create accurate parts. The process will also become cost-effective in this case.

How are aluminum prototypes used in creating industrial components?

3D aluminum prototype manufacturing has many applications in different industries. The prototypes created using 3D printing technology are precise and accurate. Here’s how it is applied in different industries:

- Accuracy

Industries that require prototyping services have different priorities. The prototype gives the business owners an idea of what the product will look like. They can see if the product will be worth going to the market.

Most industries are looking for precise prototyping results in order to know exactly what they are getting. 3D printing helps achieve the most precise and accurate results for industries like aerospace, automotive, medical etc.

- Innovation

Many industries are coming up with new designs and ideas everyday. The aluminum prototype manufacturers in China are coping with this innovation through 3D manufacturing and have eased the process to produce almost every design. This has enabled the industries to provide with any requirements and get the prototype manufactured no matter how complex it is.

- Flexibility

Not every plan is perfect in the first phase. The revision and changes are always required from the aluminum prototype manufacturers. The traditional methods do not provide the flexibility of the design change during production. 3D prototyping works best for manufacturing industries and industries like medical, marine, and many more.

- Durability and Strength

The prototyping processes are the requirement of every industry. Some products are to be used in the industries that have to endure the pressure and stress of manufacturing machinery.

The prototypes of these products are tested for durability and strength. The aluminum prototype manufacturers keep this as a priority and use aluminum alloys that are stronger than the others for these industries.

What are the applications of 3D aluminum China prototype manufacturing in different industries?

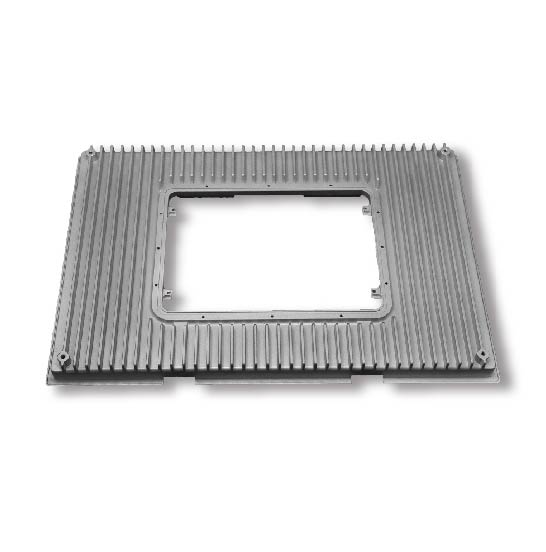

Aluminum is the most widely used material in the prototype manufacturing industry. It has desirable properties for many industries. The aluminum prototypes are strong and have an oxidized outer layer making them resistant to corrosion. It can handle the production of complex parts and this makes it the favorite prototyping material in every industry.

Aerospace

The aerospace industry is constantly changing every day. The requirement of new and more innovative designs has made the industry look at budgetary options. Aluminum prototype manufacturers in China are taking advantage of this requirement and have opened the option of using the technique. The lightweight of aluminum makes it the perfect choice for aircraft. The aluminum prototyping gives fast prototypes and helps in the design changes hence making the production of aerospace components faster and cheaper.

Medical

The medical industry is very sensitive and each component used in the industry is utilized in fragile processes. The parts have to be accurate as every centimeter counts. Aluminum prototype manufacturers build prototypes for the industry to test the designs before the products go to the industry. The design is perfected through prototyping and the end result achieved is super precise.

Automotive parts

The aluminum prototypes have high corrosion resistance and are strong. This is why aluminum prototype manufacturers in China use these in the mechanical and structural components of automotive. The prototypes are light-weight and help in designing each part with revision.

Its strength and durability also make it ideal for the production of these parts. Structural parts are mostly required to be light-weight. The design of these parts also changes a lot and the industry is highly innovative. The potential of aluminum prototypes for the change makes it highly useful in the production of structural parts in the automotive industry.

What are some of the 3D printing processes used by prototype manufacturers?

Most advanced technologies and most reliable prototyping techniques are used by prototype manufacturers in China. 3D printing processes are also an important part of manufacturing prototypes.

Some of the 3D printing processes used by prototype manufacturers are:

Selective Laser Sintering

SLS or Selective Laser Sintering are used by manufacturers for the fast production of 3D prototypes. The process achieves rapid results and accurate prototypes. Since it is an additive process, no waste is obtained making the process more cost-effective for the customer. The process adds value to every manufacturing process by providing a fast turnaround and allowing duplication.

Selective Laser Melting

The manufacturers in China make use of the process to achieve precision. The 3D prototypes are manufactured at a high speed providing fast design decisions for the customers. The manufacturers at 3D prototyping shops use melted metal and weld it onto the design inside the seal chamber. The process is feasible for low volume projects.

Fused Deposition Modelling

The process of fused deposition modeling (FDM) is used at Sunrise to achieve high productivity. FDM requires a digital design converted into a CAD file. The automatic process lays down the melted material from the nozzle of machinery layer by layer and is completely controlled by an encoding program. It is inexpensive, easy-to-use, and reliable.

What prototyping advantages are offered by aluminum prototype manufacturers to industrial users?

Prototyping is not just limited simply to manufacturing anymore. Aluminum prototype manufacturers are providing services in innovative ways to cater to growing businesses.

Rapid Prototyping

The most important service of all is, of course, the prototyping itself. The aluminum prototyping manufacturers turn any design into a prototype rapidly. It speeds up the time to market for industrial users. Reasonable cost, efficient manufacturing, and timely delivery is provided to them.

Machining and Finishing services

The rapid prototypes are not manufactured in the ideal form. They need machining and finishing to get the proper end result. The one-stop-shops in China provide all these services starting from designing and ending in surface finishing techniques. The prototype generated are CNC milled, CNC lathed, polished, anodized, and much more to achieve a perfect prototype. The industrial users don’t have to take their prototypes to any other place with these services.

Quality Testing

The prototypes that these aluminum prototype companies create are then tested for quality. Many techniques are used to test the functionality, surface, or physical properties of prototypes. The prototypes have to meet the global standards as well as the customer requirements. The industrial users don’t have to worry about the quality with these standards set in place especially for ISO 9001 certified manufacturers in China.

Engineering and Development Consultancy

The industrial users mostly don’t have the complete knowledge of their required parts. The design and production is better managed by an engineer who has the know-how of each product. This consultancy is provided by the prototyping one-stop-shops in China. Qualified engineers take care of the design or give their suggestions to achieve better results. This helps the industrial users to avoid changes to the design after manufacturing.

What are the features of aluminum alloy rapid prototypes that make them so popular?

Aluminum alloys are the most popular choice by prototype companies in China as well as other parts of the world. This is because of the advantages that aluminum alloys have over other metals.

Some of the features of aluminum alloys that make them a popular choice are:

- Aluminum alloy prototypes have far higher machinability than other metal prototypes. The other metals might be stronger than aluminum alloys but the fast machinability makes it the best choice for prototype manufacturers.

- Aluminum alloys provide precision that no other metal can. The accuracy achieved by aluminum makes it the favorite of every manufacturer. The machining processes that are applicable on aluminum yield the most precise results.

- Aluminum alloys create master prototypes using casting methods. The liquidity of aluminum alloys is outstanding making it take the shape of mold it flows in. The flawless flow of liquid aluminum helps in getting the required form easily.

- Aluminum prototyping manufacturers enjoy the corrosion resistance offered by aluminum. The metal and its alloys form an oxide layer that is only a fraction of a millimeter protecting the prototype from any harmful effects.

- Aluminum is lighter in weight but provides better strength to the prototype than any other metal of the same weight. This makes it the favorite choice of manufacturers in the industries like aerospace that require lighter parts.

What characteristics of an aluminum prototype should a manufacturer focus on during production?

The production of prototypes depends upon the requirements of the clients. The priorities of the customer should be the priority of aluminum prototype manufacturers but some of the common characteristics that an aluminum prototype should have include:

Affordability with quality

It is often thought that a cheap aluminum prototype is not good in quality or a good quality prototype has to be expensive. This should not be the case. The manufacturer should focus on providing the best aluminum prototype in the price range of the customer. The prototype should be as close to the required material as it can be.

Meeting the global standards

The aluminum prototype should meet the global standards of quality in case the customer wants to export the part. It should be able to pass the certifications like CE certification that make sure the health of the produced part is intact. Most of the manufacturers in China consider this characteristic while manufacturing the aluminum prototypes.

Requirements by the Client

The aluminum prototype should meet all the requirements of the client. The design provided by the client should be prototyped exactly with the required material. The prototype should be produced as early as possible to let the customer market it faster.

What materials/alloys other than aluminum can be used by prototype manufacturers in China?

The prototyping capabilities of many manufacturers in China provide the freedom of choosing any material for the prototypes. Many advanced technologies like CNC machining, 3D printing, SLA, SLS, etc have made the process possible for every material. However, aluminum is amongst the most preferred alloy out of all due to its numerous benefits.

Some of the materials most commonly prototyped by manufacturers in China are:

Brass

Brass is a flexible material used in rapid prototyping. It is a corrosion-resistant, gold-colored copper-zinc alloy. Unlike aluminum and many other metals, they are easily deformed when they are at normal temperatures. This makes the prototyping of this material easier. They are easy to machine and are even recyclable.

Copper

Copper is very difficult to machine but its alloys are a universal element for electrical applications due to high thermal conductivity and good corrosion resistance. Its toughness makes it less flexible but its applications make it attractive for the prototype manufacturers in China.

Titanium

Titanium has the ability to be flexible when prototyped. It is corrosion resistant even in water. This makes titanium find its application in the marine industry. The metal can easily be machined by any machining processes therefore, prototype manufacturers in China don’t have to make that much of an effort while prototyping Titanium.

Zinc

Zinc is the most popular material after aluminum that prototype manufacturers use in China. The high strength and hardness of zinc alloys make them ideal materials for this process. Even with high strength, it is easier to machine this metal.

Which software is used by aluminum prototype manufacturers for the process of 3D prototyping?

The process of 3D prototyping mostly depends upon different software. The design and the automation of 3D machinery all starts with software.

The software in 3D prototyping is mainly characterized into 3 parts:

CAD tools

These tools and software are used in the designing of the prototype. The quality of the design is improved using CAD. The software is used to define the curves, surfaces, and solids in a 3D space. It also shows the internal structures of the design in addition to the information on materials, processes, dimensions, and tolerances. The software shows the overall look of the prototype.

Freeform Modeling Tools

Some 3D software used in the prototyping solve more complex issues of the design. The 3D sculpting, surfacing, design intent modeling, all are solved using this type of software. Mold making, CNC machining, 3D printing, automated die casting, and wherever automation is required, freeform modeling tools take care of the complications.

CAM program

The computer-aided manufacturing software converts the CAD design into the G-code for CNC machining. The software takes the design and each specific of the design is processed. The design is completely turned into a language that the machine will understand. It will ask for the tools that you are going to use for the process and will accordingly generate the code.

Machining software

The code is entered to the machinery that is automated. The 3D processes like SLA will have a control system that will take the code and will translate it for the machinery. Sometimes, an external controller is also attached to the machinery but the purpose of both is to translate the code generated by CAM software.

Is aluminum prototype manufacturing an additive process?

The processes and techniques used by aluminum prototype manufacturers are not the only additives. Different processes are used to create aluminum prototypes.

Some of the additive manufacturing processes for prototyping are:

- Fused Deposition Modelling (FDM)

- Selective Laser Sintering (SLS)

- Stereolithography (SLA)

- Selective laser melting (SLM)

- Laminated Object Manufacturing (LOM)

- Daylight processing

- Binder Jetting

The additive manufacturing processes are more affordable as there is less waste in production. The layers are created over each other from the required material using one of the methods mentioned above.

But subtractive processes are also used in aluminum prototype manufacturing. The process removes aluminum from the aluminum block to achieve the prototype.

Subtractive prototype manufacturing involves the following processes:

- CNC milling

- CNC lathing

- CNC cutting

- CNC sawing

- CNC turning

The process does not involve the layering but produces the prototype carved out of a metal block. Higher structural integrity is achieved with such a process. The prototype manufacturers also analyze the product more accurately.

Which subtractive prototype manufacturing processes are used by Sunrise as an aluminum prototype manufacturer in China?

Sunrise metal is a high-rated aluminum prototype manufacturer in China. It uses different subtractive manufacturing processes for the production of prototypes.

Some of them are:

- CNC boring

CNC boring process is the sub-category of CNC lathing. It drills the hole in the aluminum prototypes. Sunrise metal uses this process to drill the holes either horizontally or vertically using its spindle. The material where the spindle moves and bores a hole is subtracted from the workpiece.

- CNC milling

CNC milling is employed by Sunrise Metal aluminum prototype manufacturers to remove the material from the workpiece. This is done from every axis and through different spindles as required by the design. The speed and pressure is kept different according to the custom requirements.

- CNC cutting

Different cutting machines like CNC plasma cutting machines, CNC oxy-fuel cutting machines and CNC waterjet cutting machines are used by Sunrise metal to cut the workpiece according to the requirements. These processes are employed to subtract the material from the workpiece.

- CNC sawing

The CNC sawing machining at Sunrise metal is automated machinery that moves the saw up and down fastly. This is controlled by a feeler pin and depending upon the limitation of axes, it can cut the workpiece from everywhere. It is not rotary as a CNC milling process.

- CNC turning

For creating cylindrical parts, Sunrise metal uses the CNC turning process. It cuts the part in a way that the cylindrical shape is obtained. It is also the subcategory of CNC lathing.

Does prototyping manufacturing require expensive tooling and specialist equipment?

The process of prototyping used by most prototype manufacturers in China is cost-effective. Every piece is made on a very low budget. Although the machinery used in the process is more expensive than conventional equipment. The CNC machining processes require no tooling at all which makes it cost-effective. Although rapid tooling prototyping requires the tooling services it costs around 60% of the tooling required in traditional tooling processes.

The parts produced by prototype manufacturing show design flexibility and can imply changes at any point of production. Conventional tooling can cost a lot more if any change is required in the production and the result is also delayed. The prototypes obtained from expensive tooling are more reliable and accurate.

The specialist equipment also supports low-volume production therefore, the high price of the equipment is covered in all these advantages during the first or second year of purchase.

What kind of tooling is used by Sunrise Metal for aluminum prototype manufacturing?

Sunrise uses the most advanced die casting prototype tooling for aluminum prototype manufacturing. They yield parts in quicker time and can run faster feed rates, without wearing out quickly. Excellent results can be obtained using these tooling.

Some of the tooling used by Sunrise metal for aluminum prototype manufacturing includes:

- Pre-hardened mold steels for cavities, including P20, H13, 2344. These are versatile with good toughness levels. H13 is especially capable of catering to high-quality requirements. Investment in this type of tooling reaps large returns and significant cost reductions in the long run.

- The designing of these parts is also done by state-of-the-at software present at the prototype workshops. Advanced 3D printing equipment as well as the most expensive and reliable CNC machining equipment is used in the dedicated facilities of Sunrise metal for the production of tooling.

The aluminum prototype manufacturing process at Sunrise Metal includes excellent finishing techniques. We use processes like chromate, powder coating, wet painting, e-coating, anodizing, etc.

How is rapid tooling made possible by aluminum prototyping manufacturers?

Most aluminum prototype manufacturers are one-stop-shops that also have workshops dedicated towards tooling of those prototypes as well as other manufactured products. The rapid tooling of the manufactured prototypes is mostly done by the same equipment as used in prototypes.

Different processes work in the unison of aluminum prototyping to fabricate molds. It is the process of producing tooling at a lower cost and in a faster way. It uses the process of rapid prototyping to fabricate a tool for prototypes.

Rapid tooling provides aluminum prototype manufacturers with certain advantages:

- They don’t need conventional tooling methods where small volume is required.

- The time required for rapid tooling is way less than conventional tooling.

- Rapid tooling is a cheaper option than conventional tooling.

Which CNC machining is used by Sunrise that makes it a high-tech, leading aluminum prototype manufacturer in China?

Sunrise metal is known for the high-tech equipment it uses that makes it one of the leading aluminum prototype companies in China.

The most advanced equipment is listed below:

7-axis milling and turning machine

The equipment has milling and turning tools employed in it. The tools automatically change and move from their positions. The movement of the tools is in 7 axes meaning the machining takes place from every side of the workpiece. The machine offers a stroke of Ø658*1011MM.

EDM machines

The most advanced EDM machinery is present at Sunrise metal aluminum prototyping centers. The hard metals are easily prototyped using this machinery. Therefore, whatever the required material of our customers might be, Sunrise can provide prototypes from it.

Wire cutting machine

Sunrise metal has employed the most advanced wire cutting machine. The complex shapes and prototypes are easily achievable using this machinery. The prototypes generated from this machinery also show less roughness than other machining processes.

These are only some of the advanced machinery used at Sunrise metal. Sunrise is proud to have the most futuristic machinery making it the premium aluminum prototyping manufacturer in China.

How do CNC operators at Sunrise produce complex aluminum prototype parts?

CNC operators at Sunrise follow a quality-based process to achieve complex prototype parts.

The requirements of the customer are read and this is how the process takes place:

- The idea of the customer is converted into a CAD file. It is a digital file that learns all the features required.

- The design is then fed to the CAM system. It generates the code which is to be fed to the CNC machinery.

- The requirements and the movement of the tools are also fed to the CAM controller. Each movement is recorded by the software and a G-code is generated.

- The code is then fed to the controller of the CNC machining center. The tools employed in the center are according to the requirements of the design.

- After the CNC machine and the workpiece is set up, the program is run.

Which CAM software is the most commonly used by rapid prototype manufacturers?

The CAM software used by different aluminum prototype manufacturers depends upon the requirements. Many CAM softwares are free but do not provide the features like 3 axes or more conversion. More and more complex shapes require more advanced CAM software.

The choice of CAM software depends upon:

- The complexity of the prototype

- The material used in the aluminum prototype

- Price of the CAM software

- Accuracy of the software

What equipment does Sunrise metal use for quality inspection?

Sunrise metal has gained immense popularity in the die casting industry in the past few years. Our efficient systems carry out quality checks in testing laboratories to ensure the quality of products. We place a lot of importance on the control and inspection of all our manufacturing processes to comply with regulatory and customer requirements.

Some of the common technologies they use are as below.

- Zeiss CMM

For keeping a regular check on the everyday applications, we also use coordinate measuring machines. These top-grade machines take quality assurance to a brand-new level. Zeiss CMM machines are used for processes that require high-speed scanning and optimized precision at all levels. It uses metrology technology that is affordable yet world-class. At Sunrise, we combine it with high-tech machinery that provides flawless production capability.

This multidimensional technology allows us to maintain a level of quality that cannot be matched by many competitors. Accurate data, high measuring speed, and top accuracy measurement results can be achieved for even the most complex manufacturing processes.

- Spectrum Analyzer

This is advanced inspection equipment that keeps a check on the raw materials of the products.

- X-Ray Detector

For taking an in-depth view of the product and to minimize flaws in pressure die casting products, we have now introduced the use of X-ray detectors. These detectors make it easier to see the inside of the die casting products, as well as detecting and measuring the porosity and other cracking defects of prepared items.

How does Sunrise Metal control the quality of prototype parts?

Fabrication of several parts of machinery with the usage of a 3D computer aiding system is the specialty of Sunrise Metal. We can’t afford to compromise on the quality of prototype materials at the cost of our customer’s product quality.

We ensure all the ways which can enhance the quality of prototyping materials and rapid prototyping. We strictly follow ISO 9001 standards to make sure we follow all customer and regulatory requirements at all times.

We take note of CMM dimensions to check for the first article produced and then to examine the finished parts.

- Usage Of High-Quality Equipment

We focus on the investment of efficient tools and machinery for better production. Additionally, we keep a strict check on the quality and accuracy of the products produced by advanced equipment.

- Dedicated Staff

All of our workers are working at their utmost skills to provide the best services to our esteemed customers. Qualified and competitive workers keep an eye on the monitoring production of all the tools.

What machines does Sunrise Metal use for aluminum CNC prototypes?

Sunrise metal uses modern techniques for introducing computerized technology for creating products. These products span both industries and domestic demand with the best quality and design. Efficient, state-of-the-art machinery is utilized to make this level of production a reality.

Some of these machines are:

- Lathe Machine

This kind of CNC machine is used for high precision machining.

- Milling Machines

For rotating and cutting the tools, they are using a milling machine. This machine is particularly designed for rotating and cutting all the tools in multiple directions.

- Routing Machines

This machine offers its services similar to that of the milling machine. But the main reason for its usage is the high precision of the products produced.

- Laser Cutting Machines

Another machine that is also used for cutting tools but with the help of laser technology.

What machines does Sunrise Metal use for aluminum die casting prototyping Tooling?

Sunrise metal offers prototype manufacturing services in China for aluminum die casting and rapid prototyping. Low-volume prototyping orders of up to 200pcs are delivered within 1-2 weeks.

The machines used by us in all steps of die casting and prototyping are of top-notch quality. Some of these machines are listed below:

- High Precision CNC Machine:

The high precision CNC machine at our prototyping facility has a wide range of strokes. This results in the high precision of aluminum die-cast prototypes. The generation of efficient tools is only possible with pre-programmed software.

We are using this CNC machining software for guiding all the machinery to prepare the most precise products. This will lead to the automatic production of molds that can be used even for complex orders of rapid prototypes.

- High-Speed CNC Machine

The high-speed CNC machine at Sunrise is used for rapid prototyping. The machine works faster with a rapid tool change. With this equipment, our customers get to market their products faster.

- DMU monoBLOCK 5-AXIS CNC Machine

The 5 axis CNC machine allows us to explore and machine 5 axes on the aluminum workpiece. The machining tool can work on each axis and provide a rapid and more precise result.

- Milling Machine

For cutting and molding the metals in desired shapes, we are using milling machines. All this is possible with the presence of spindles in it, which ensures proper cutting.

- EDM

To associate the cutting mechanism with the electric spark, we are using electric discharge machining systems. Not only this, but we are also using wire EDM machines for the same purpose.

Our tooling machining not only helps us modify the tooling but also produces it from the design provided by our customers. We offer complete solutions from tooling design, manufacturing, modification, maintenance to tooling end management.