High Efficiency Aluminum Die Casting Prototypes in China

Sunrise Metal delivers high precision Aluminum Die Casting prototypes using state-of-the-art technology and qualified engineering teams. We operate with complete prototyping services with CNC prototyping, 3D printing, and prototype tooling and deal with various production materials.

We produce die casting prototypes fast! The function and design of each aluminum prototype is customized according to customer and project demand, with the finished product being exactly in line with your requirements.

Sunrise teams implement die casting methods for prototypes that rely on low tooling costs but create durable and high-strength aluminum die casting prototypes. With an extensive experience of over 10 years and rapid tooling technology, Sunrise is the most suitable option for high mix-low volume prototype orders with excellent surface finishing properties.

From design to usability, you can trust Sunrise Metal all the way.

Your Perfect Aluminum Die Casting Prototypes Made By Sunrise High Precision Manufacturing Equipment

Best Functionality & Design Aluminum Die Cast Prototypes

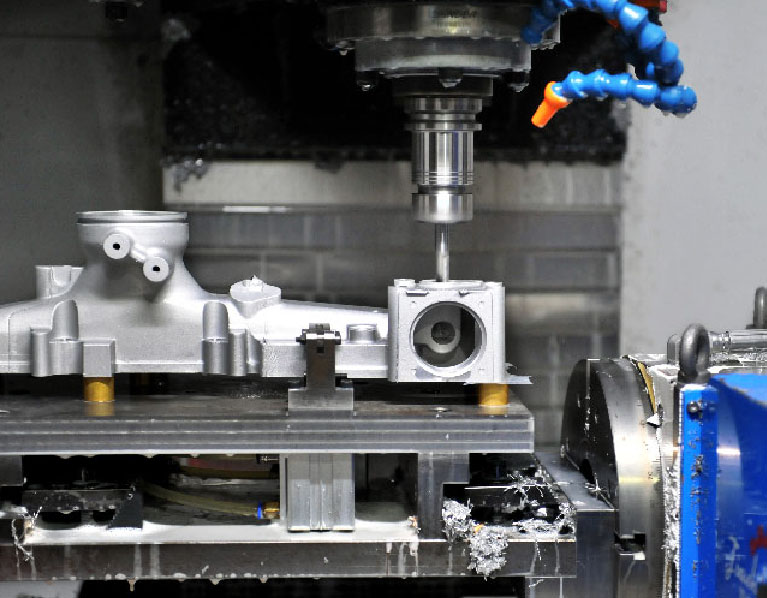

Sunrise houses the latest design and manufacturing technologies such as high speed CNC machining, 3D Design/CAD System and Simulation Software, which make it possible to build the best dies for aluminum die casting prototypes in the lowest time possible.

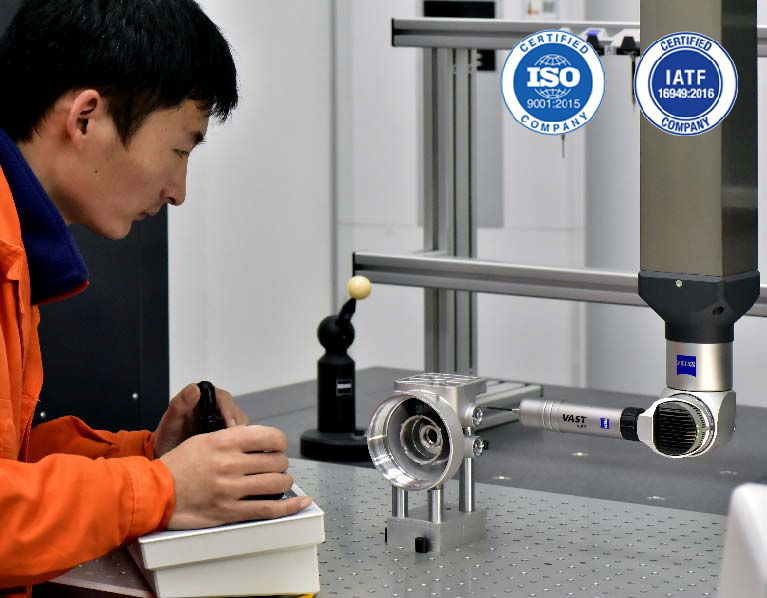

Quality assurance officers at Sunrise provide superior design support and high quality production to make sure you get the best return on your valuable time and investment. International quality control standards such as ISO 9001 help us keep results at the top as we go from testing to evaluation without a glitch.

Due to efficient die casting prototype production processes, Sunrise caters to customers with urgent and low-volume orders with a quick response service. Tooling lead times are optimized to suit your costing plans and prototyping needs.

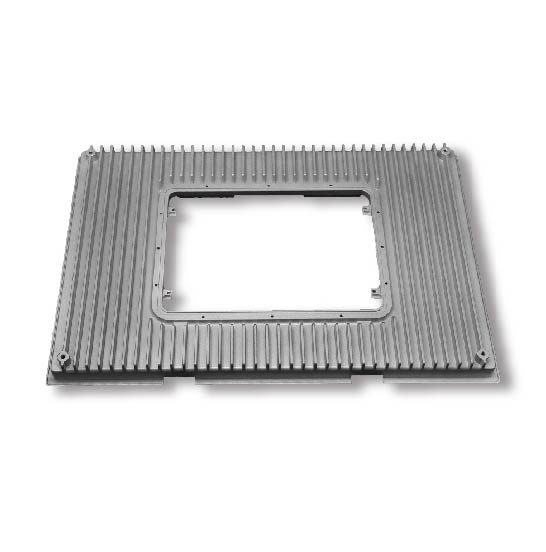

Aluminum die casting prototypes are applied to a wide variety of industries including automotive, machine production, marine, telecommunication, Commercial electronics, and many more.

1000+ Aluminum Die Casting Prototypes Manufacturing Experience From 500+ Global Clients

Prototype Production You Can Fully Trust

Aluminum die casting prototype production at Sunrise Metal is backed with years of experience and top-level engineering experience. This mix helps us make the best use of quick-turn casting prototype processes, as well as other methods that deliver efficiency at the best cost.

We are able to customize our solutions for global users – some of whom are top manufacturers and never compromise on quality. All sizes and types of industrial components, even those with intricate designs are prepared at Sunrise using fine manufacturing equipment: Mazak 7-axis turning machine, 5-axis CNC machine, and EDM machines.

We take your CAD drawings and turn them into manufacturing success!

- Advanced Equipment

- Premium Quality

- Fast Delivery

| No. | Name | Stroke | Q’ty |

| 1 | Mazak 7-axis turning&milling Machine | Ø658*1011MM | 1 |

| 2 | Mazak /Hass 5axis CNC machine | Ø850/Ø600 | 4 |

| 3 | 3-axis CNC machine center | 2000*1500MM | 1 |

| 4 | 4-axis CNC machine center | Ø250*800MM | 8 |

| 5 | 3-axis CNC machine center | 1000*600*600MM | 20 |

| 6 | CNC Lathes | Ø320*800/Ø610*1000MM | 2 |

| 7 | Sodick Wire cutting Machine | 400*400*200MM | 3 |

| 8 | EDM machine | 500*400*400MM | 2 |

| 9 | Surface grinder | 600*300*200MM | 1 |

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

Our commitment is to provide consistent, on-time delivery and enhance customers satisfaction at all stages.

No More Delays. Get A Free Consultation from Sunrise Metal Now.

Get in touch with our customer care representative or qualified engineer for all your die casting prototyping needs and skyrocket your project success today! Get more information on:

Tooling Strategies used at Sunrise & Cost-cutting methods for industrial parts & High-precision design and re-design techniques & Applications of aluminum die casting prototypes & Product development schedules & Prototype machining services.

ALUMINUM DIE CASTING PROTOTYPES: THE ULTIMATE FAQ GUIDE

One of the most important stages of manufacturing is producing a prototype of an intended product. Producing a quality prototype contributes massively to the success of a product launch.

Prototypes help manufacturers to test and predict whether a product idea is valid or not.

In this guide, you will get to know all the important information about aluminum die casting prototypes. You will get answers to all the questions you have about aluminum die casting prototypes at Sunrise Metal, your Leading die casting manufacturer.

- What Are Aluminum Die Casting Prototypes?

- What Is the Importance of Prototypes in Die Casting Manufacturing?

- What Are The Advantages Of Aluminum Die Casting Prototypes?

- What Is The Capability of Sunrise In Manufacturing Die Casting Aluminum Prototypes?

- What Factors Determine a Quality Aluminum Die Casting Prototype?

- What Die Casting Services are Provided by Sunrise Metal?

- What Factors Determine Aluminum Die Casting Prototype Lead Time?

- What Are Some of The Technologies Used for Manufacturing Aluminum Die Casting Prototypes?

- What Machines Do You Use For Making Aluminum Die Casting Prototypes?

- What Are The Processes Involved in Manufacturing Aluminum Die Casting Prototypes?

- What Is The Minimum Quantity of Aluminum Die Casting Prototypes You Produce?

- What Factors Should You Consider Before Contacting a Manufacturer for Your Aluminum Die Casting Prototype?

- Why do you choose rapid tooling over other methods during aluminum die casting prototype manufacturing?

- Which industries use aluminum die casting prototypes?

- What Determines The Cost of Aluminum Die Casting Prototypes?

- Are your Aluminum Die Casting Prototypes Precise and Accurate?

- How Do I Get a Quote for My Aluminum Die Casting Prototype?

- What Factors Do You Put in Place to Ensure The Quality of Aluminum Die Casting Prototypes?

- Do You Have Experience in Aluminum Die Casting Prototype Manufacturing?

- Why Should I Choose Sunrise Metal for My Aluminum Die Casting Prototypes?

What Are Aluminum Die Casting Prototypes?

Prototypes are the first versions of a manufactured product from which all other products are made. A prototype contains the most important features of the final product.

The primary purpose of a prototype is to test a product idea to see if it meets the requirement of the manufacturer.

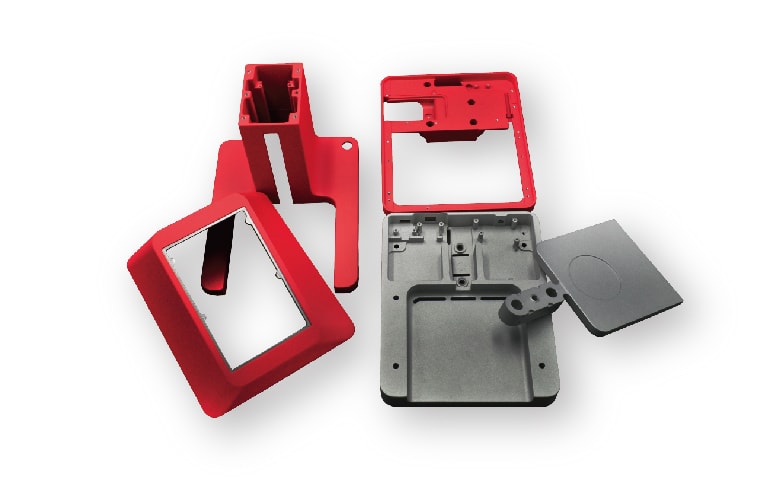

Aluminum die casting prototypes are some quick turn out products made from prototype tooling, aluminum die casting, and secondary processes like CNC machining, surface finishing, etc.

Aluminum die casting manufacturers use prototyping to convert their aluminum die casting product idea into tangible forms that can be put to test.

Sunrise Metal is your one-stop aluminum die casting prototype manufacturer in China. We have over 10 years of aluminum die casting prototyping experience. Our rich experience together with our high precision manufacturing equipment helps us to produce perfect aluminum die casting prototypes for you. Contact Sunrise Metal today for all your aluminum die casting prototypes.

What Is the Importance of Prototypes in Die Casting Manufacturing?

Prototypes are very important in aluminum die casting manufacturing. In an era that clients demand perfect products and high standard services, manufacturers need to attach the manufacturing of prototypes with all seriousness.

As the leading aluminum die casting prototype manufacturer in China, Sunrise Metal have created highly effective systems that enable us to manufacture perfect prototypes that meet our clients’ expectations.

The following are some of the advantages of prototypes in aluminum die casting manufacturing:

- Prototypes provide an accurate and precise physical representation of the desired final product.

- They help to detect defects in your model so that the final product can be perfected. This helps to avoid the unnecessary cost that would have been incurred if defective products are produced in mass production.

- It gives you the opportunity to improve your final product. When prototypes are made, product developers are able to carefully evaluate and give positive feedback. The useful insights or suggestions from team members developing the product can be used to improve the final product.

Also, you can send your prototype to your intended users or customers for them to test and give your positive feedback. The feedback from your clients is so important since they are the ones going to use your final product. Your intended users can give you useful recommendations to help you improve on your final product after testing your prototype.

- It saves time, cost, and effort.

A prototype is just the first example of the intended product to be produced and changes can be done to improve it any time in the manufacturing process. Because only one or a few prototypes of the final product is produced, any changes or corrections done do not affect the manufacturer severely in terms of time, cost, and effort. The time, effort, and money used to correct prototype defects are insignificant compared to that spent on products during mass production.

- Prototypes help manufacturers to better understand their product idea and final product. This is because prototypes convert product ideas into physical product forms that can be seen, touched, felt, and tested.

- Prototypes help to validate a product idea before mass production. When the prototype meets the intended product requirements after testing and evaluation, manufacturers become convinced that their product idea is valid.

What Are The Advantages Of Aluminum Die Casting Prototypes?

Aluminum die casting prototypes have many advantages over other prototypes because of Aluminum’s unique properties. The following are some of the advantages of aluminum die casting prototypes over CNC machined prototypes:

- The same prototype material is used for mass production in the future and this makes the prototype to contain the same features as the final product. This will help you have a very good idea about how your final product will look and perform.

- The same process for creating an aluminum die casting prototype is used during mass production. This helps maintain consistency during mass production.

- The characters and specifications of the aluminum die casting prototype is the same as the mass production parts. It helps you to save costs from the request of hundreds of pieces.

- Aluminum die casting prototypes can be used as small batch production that can be launched to the market, therefore saving you a lot of time that mass production would take.

What Is The Capability of Sunrise In Manufacturing Die Casting Aluminum Prototypes?

As the leading aluminum die casting prototype manufacturer in China, we have an experienced workforce and use the best technology for our production. This together with our highly efficient manufacturing systems help us to produce excellent aluminum die casting prototypes that meet all your requirements.

Sunrise Metal have been producing aluminum die casting prototypes for over 10 years. We boast of a very experienced engineering team and workers who have a very rich understanding of aluminum die casting prototype manufacturing.

Our engineering manager has 23 years of experience in the aluminum die casting prototype manufacturing industry. This pool of experience from our expert engineers and workers makes us highly capable to serve you with the best aluminum die casting prototypes.

Your company can trust us, China’s leading aluminum die casting prototype manufacturer to meet all your prototype needs. Below as some of Sunrise Metal’ capabilities

In House Tooling

Tooling is critical to the success of aluminum die casting prototype and parts manufacturing. Sunrise has an In-house aluminum die casting tooling shop that meets different project demands at a faster rate.

We have a remarkable ability to provide high-quality aluminum die casting prototypes and products due to our competent and cost-effective in house tooling.

The toolmakers at Sunrise’ In-house tooling shop are highly experienced and they have the ability to design and create tools that meet the requirements of our customers.

The tools manufactured by Sunrise are accurate, very precise, and able to mold aluminum prototypes and parts with tight tolerance and complex shapes.

Die Casting

Our competent engineering team with invaluable experience in aluminum die casting makes Sunrise capable to offer a 1-stop solution for all your aluminum die casting projects.

We also have fully equipped and efficient die casting machines that help us to produce highly accurate die casting aluminum prototypes.

Highly Precise CNC Machining

Sunrise uses highly advanced CNC machines that enable us to create highly accurate molds quickly for manufacturing aluminum die casting prototypes and parts.

We use our highly precise CNC machines in our in house die casting shop to produce excellent surface finishing on aluminum die casting prototypes and parts.

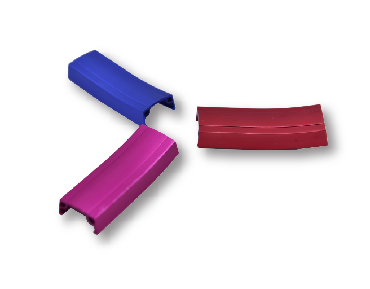

Surface Finishing

We offer variable surface finishing treatments on your aluminum die casting prototypes and parts.

Our modern surface finishing treatments do not only add value to your aluminum die casting products, they make them super attractive to your customers.

Our four dedicated facilities, 182 employees and strict quality control measures empowers us to produce high quality aluminum die casting prototypes that meet all your requirements

What Factors Determine a Quality Aluminum Die Casting Prototype?

Quality aluminum die casting prototype possesses unique properties that makes it capable to perform to desired expectation. It is able to meet the specific needs for which it was made.

The following factors determine a quality aluminum die casting prototype.

Specifications

Without proper prototype specifications, you cannot produce a quality prototype that would meet your needs.

Having in mind the exact need your intended product is going to meet, you need to determine the requirements or specifications of the prototype that would make it capable to address your problem.

In order to produce a quality aluminum die casting prototype, the manufacturer also needs to know and understand the exact specification of the prototype.

The manufacturer needs to find out from the client what the requirements of the prototype are. The client should also be able to communicate in detail the exact requirements or specifications of the intended prototype to the manufacturer.

Specifications such as strength, tolerance, wall thickness, tolerance, level of precision, weight, etc. need to be known and communicated to the manufacturer.

Materials

After determining the specifications of the aluminum die casting prototype, you need to determine the type of aluminum alloy for your prototype. You need to select material that will meet your requirements.

Our engineers and team of experts at Sunrise Metal will be able to guide you to choose the right aluminum alloy for the success of your prototype project.

Manufacturing process

The next factor that determines the quality of the aluminum die casting prototype is the process for manufacturing.

With the knowledge of your aluminum die casting prototype requirement, Sunrise’s team of experts can determine the exact tooling and casting processes for your aluminum prototype.

We will look into detail the processes we use for manufacturing aluminum die casting prototypes at Sunrise.

Standard of Operation

In order to produce high-quality aluminum die casting prototypes, manufacturers need to follow internationally recommended standards.

Sunrise Metal, China’s No. 1 aluminum die casting prototyping manufacturer has a reputation of following very strict quality standards during production. This helps us to produce quality aluminum die casting prototypes that meet your requirements.

Machinery

The type of machines used for manufacturing aluminum die casting prototypes also contributes to the quality of the prototype.

As your No. 1 aluminum die casting manufacturer in China, we have highly precise CNC machines that are used in creating highly accurate molds for your prototypes. We also have highly efficient aluminum die casting machines that help us to produce high-quality prototypes.

Our well-equipped laboratory aids us to conduct all the needed tests to make sure our prototypes meet the highest quality standards.

What Die Casting Services are Provided by Sunrise Metal?

Sunrise Metal provides high-quality services to over 500+ clients worldwide in the following categories:

Aluminum Die Casting Mass Production

Our high precision manufacturing equipment helps us to serve you with perfect aluminum die casting parts and products.

We have a hard-earned reputation of providing classic aluminum die casting manufacturing solutions for years.

Join over +500 clients to have a feel of our 2500+ high-class aluminum die casting parts at an affordable cost. You have a wide range of customized manufactured parts to choose from at Sunrise Metal. Our fully automated production system helps us to maximize production to suit your budget for even complex aluminum die casting parts.

Aluminum Die Casting Prototyping

We understand your need for highly efficient, precise, and perfect products to meet your requirements. That’s why we combine innovation, technology, experience, and understanding of your product requirement to manufacture prototypes that perform to your expectations.

With our highly precise rapid prototyping machines, you are assured of getting very accurate aluminum die casting prototypes.

You can count on your LEADING aluminum die casting prototype manufacturer in China to get all your prototype parts delivered to you at a faster rate with no room for errors.

CNC Machining

Sunrise Metal is your 1 stop high precision CNC machining manufacturing service provider in China. Get all your machined aluminum die casting parts with accurate features that meet all your requirements from Sunrise Metal.

We are ISO9001 & IATF 16949 certified professional CNC precision Machining manufacturer with over 10 years of experience.

We have ultra-precise CNC machines like Mazak 7 axis and Haas 5 axis, with a tolerance of up to 0.005mm. Our highly precise measuring instruments also help us to take accurate measurements during machining, giving no room for error on our machined parts.

You are assured of on-time delivery of accurate aluminum machined parts, thanks to our efficient production system and rapid CNC fixture technology.

Our precise CNC machined parts are used in industries like :

Automotive Engine & Electronics,

Medical & Health Care devices,

Marine Electronics,

Industrial & Commercial,

Communications & Networking,

Aerospace Electronics,

LED Lighting, etc.

Surface Finishing

With over 2000+ die casting parts surface treatment experience for +500 clients, we are your best bet in getting a perfect surface finish for your aluminum die casting parts.

We help you choose the right surface finish for your aluminum die casting parts with quality control in mind. This means you need not worry about getting any external service support when working with Sunrise Metal. Indeed, we are your all in one aluminum die casting service provider.

What Factors Determine Aluminum Die Casting Prototype Lead Time?

They are many factors that determine aluminum die casting lead-time. Some of these factors are parts size, complexity, variation, and accuracy level required.

Prototypes that are more complex have a higher lead-time. Highly accurate prototypes also increase the lead-time.

Typically, our standard lead-time for rapid prototyping a small batch can be a few weeks and that of rapid tooling can be up to a month.

After prototype tooling ready, we are able to prototype 100 aluminum die casting parts within 1-2 weeks.

Because of our highly efficient machining processes and superior engineering capabilities, we are able to reduce the standard lead-time by up to 50%. This helps us to deliver prototypes to our clients faster.

Comparatively, we deliver aluminum die casting prototype services at a much faster rate than most companies do.

Other factors that affect lead times are manufacturing processes used in producing prototypes.

At Sunrise, our aluminum die casting prototypes manufacturing process are:

- Rapid mold making and die casting parts

- Pure CNC machining

Sunrise Metal, China’s leading aluminum die casting manufacturer employs highly efficient manufacturing processes that help us to deliver products to our clients on time.

What Are Some of The Technologies Used for Manufacturing Aluminum Die Casting Prototypes?

There are many technologies used for manufacturing aluminum die casting prototypes. For the purpose of this guide, we will limit ourselves to the ones used by Sunrise Metal.

Sunrise Metal uses two main technologies for manufacturing Aluminum die casting prototypes.

- Rapid prototyping

- Rapid Tooling and Die casting.

Rapid Prototyping

Rapid prototyping is a technology used for making aluminum prototypes at a faster rate.

Rapid prototyping uses the latest technology to make physical models from a CAD file. It is a great way of producing high quality and precise aluminum prototypes quickly.

The Different Types of Rapid Prototyping.

There are two types of rapid prototyping technology, they are:

- additive prototyping

- subtractive rapid prototyping

But there are many technologies under these two rapid prototyping types. They are listed below:

CNC machining

Selective Laser Sintering

Fused Deposition Modeling

Laminated Object Manufacturing

Solid ground curing

Selective laser melting

You need to note that all the rapid prototyping technologies listed above are additive manufacturing methods except CNC machining.

Even though the additive methods are numerous, they have some drawbacks and material restrictions.

Rapid Prototyping Technologies Used By Sunrise Metal

Sunrise Metal use CNC machining for aluminum rapid prototyping. But we are not limited to CNC machining. We also use other rapid prototyping technologies to give our clients options that suit their projects.

CNC Machining Rapid Prototyping

The CNC machining is a subtractive rapid prototyping technology whereby a prototype is machined from a solid material. Material is removed from metal or workpiece by the CNC machine to form a desired prototype. Different materials can be used for this purpose.

At Sunrise, we use CNC machining technology to produce high quality, precise and accurate aluminum die casting prototypes for our clients. Depending on your prototype requirement, we can choose a suitable material for CNC machining. Some of the materials used are aluminum, magnesium, zinc, etc.

Rapid Tooling Technology

This technology uses the CNC machine for mass-producing prototypes. This is a very good method for manufacturers who need statistical data for their products.

It is important to note that rapid tooling is not the same as rapid prototyping, even though they use the same technology. In simple terms, rapid tooling is used for producing molds at a faster rate.

Sunrise mainly used rapid tooling to manufacture precise molds for aluminum die casting. Also known as production tooling, rapid tooling can also be used to produce higher volumes of prototypes or products for testing.

If your goal is to produce low volumes prototypes or parts, you need to use rapid prototyping.

For higher volumes of prototypes or parts, you need to create the molds using rapid tooling technology, then use the molds to produce multiple prototypes through die casting.

The accuracy of these multiple prototypes would be the same as the final product, so they are perfect to test your products and get statistical data.

Sunrise Metal, China’s leading aluminum die casting prototype manufacturer provides both services and we will be happy to serve you using the technology of your choice.

We have a highly advanced rapid tooling technology that makes us capable to produce precise molds for quality aluminum die casting prototypes.

What Machines Do You Use For Making Aluminum Die Casting Prototypes?

As China’s leading aluminum die casting manufacturer, we use highly advanced machines for production that ensures the accuracy of both prototypes and final products.

These are some of the machines we use for tooling or manufacturing molds for aluminum die casting:

High Precision CNC machine

The high precision CNC machine is mainly used for rapid tooling and parts production.

Sunrise Metals use the DMU monoBLOCK 5 – axis CNC machine to create highly precise and efficient molds quickly.

Our highly powered DMU monoBLOCK 5- axis CNC machine makes it possible to create very complex molds with high accuracy in the shortest time.

The DMU monoBLOCK 5 – axis CNC machine has large doors that ensure access to the work area. It has extensive cooling measures and multi-sensors. It has many tables that make room for turning and milling. The machine is automated which makes it suitable for specific automation processes.

The molds created by the high precision CNC machine are used for producing aluminum die casting prototypes or parts through die casting.

The prototypes produced through die casting go through a secondary process called CNC machining where unwanted parts on the prototype are removed. This is to enhance the smoothness and accuracy of the prototype or part produced.

The CNC machined prototypes or parts are then given surface finishing treatments. We will go into details of these processes later in this guide.

Coordinate Measuring Machine

Sunrise uses this machine to take an accurate measurement of molds using sensors. It has the ability to take measurements of objects that cannot be reached. It’s inbuilt 3 axis system enables it to take measurements in all directions.

High-Pressure Cold Chamber Die Casting Machine.

The cold chamber pressure die casting machine is used for casting aluminum prototypes using molds created by rapid tooling.

The cold chamber pressure casting machine has the following components:

- Cold chamber where the melted aluminum metal is poured into

- Hydraulic system with a cylinder and a piston. This piston pushes the molten metal into the mold cavity.

- Mold cavity that is made of steel. The melted aluminum metal takes the shape of the mold cavity after it’s been introduced into it.

- Ejector that is operated to eject or remove the die casting or solidified aluminum prototype.

What Are The Processes Involved in Manufacturing Aluminum Die Casting Prototypes?

There are two main processes involved in manufacturing aluminum die casting prototypes. They are:

- Rapid Tooling/Rapid Mold Creation.

- Die Casting Aluminum Prototype.

Rapid Tooling/Rapid Mold Creation

This is where the mold or die for the prototype is created.

- Design Aluminum Prototype Tool/ Mode.

The first step in creating an aluminum die casting mold is to design the mold. When designing the mold, specifications like draft, fillets, parting lines, boss and ribs need are taken into consideration to ensure a high-quality mold is manufactured.

- Create a Model for Aluminum Prototype Tool Design.

After designing the mold for the prototype, you need to create a 3D model of the mold using Computer-Aided Design (CAD) technique.

The last step in aluminum die casting mold creation is rapid tooling using a DMU monoBLOCK 5 – axis CNC machine. This is where the mold for die casting is created quickly with the DMU monoBLOCK CNC machine. The high precision automated CNC machine converts solid steel into the shape of the mold design.

Die Casting Aluminum Prototype.

After manufacturing the mold, the next step is to make the aluminum die casting prototype using the cold chamber die casting machine.

The mold created by rapid tooling is properly fixed into a cold chamber die casting machine.

Melted aluminum metal is poured into the cold chamber. The mold or die at this stage is closed.

The piston in the cold chamber pushes the metal into the mold cavity under high pressure. The mold is opened during this process. The metal is held in position by the piston until it becomes solid.

The manufactured aluminum die casting prototype undergoes secondary processes like grinding, heat treatment, and surface finishing.

What Is The Minimum Quantity of Aluminum Die Casting Prototypes You Produce?

Sunrise Metal accepts low to medium volume orders with a high mix. But because of our desire to help our customers, we accept a minimum of 1 pcs of aluminum die casting prototype requests. This is due to our commitment to be a one-stop solution for aluminum die casting.

That means we can manufacture a single aluminum die casting prototype for you at the first stage of your product development. We have the ability to supply you 100pcs of aluminum die casting prototypes in 1-2 weeks.

We can also produce large quantities of aluminum die casting prototypes from 100-5000 pcs.

What Factors Should You Consider Before Contacting a Manufacturer for Your Aluminum Die Casting Prototype?

Before contacting a manufacturer for aluminum die casting prototype, you need first set clear goals. You need to know what you want to do or achieve.

When you have clarity about your objectives or goals, it will guide you to determine the exact aluminum die-casting prototype to request from the supplier.

You need to know exactly what you need from the die casting manufacturer. You need to have a clear idea about the intended product in order to request a prototype from a manufacturer. Ask yourself this question. “What aluminum die casting prototype do I need in order to achieve my objective?”

After this, you need to understand the specifications of the aluminum die casting prototype or product you need. What is the size, thickness, weight, precision, etc. of the aluminum die casting prototype you want. Remember, the simpler your design, the better. This will help you reduce your cost as well.

If possible, draw and indicate all the dimensions of the aluminum die casting prototype you want.

You can contact Sunrise Metal to help you with the drawings and prototype design of your desired product. The prototype design is crucial for the success of your project.

You need to also plan on your budget. How much do you expect to spend? Before you can do this, you need to determine the quantity of aluminum die casting prototype you need.

Why do you choose rapid tooling over other methods during aluminum die casting prototype manufacturing?

The CNC machine is used for rapid tooling when making aluminum die casting prototypes mold because of the following reasons:

- It Helps to Produce Aluminum Die Casting Molds Quickly.

Time is very important in manufacturing. The faster an aluminum die casting tool is produced, the better. This will ensure molds are available for die casting the prototype within a short time. It will also help clients to get their prototypes on time so that they can finish their projects as planned.

Sunrise has a capable engineering team and highly advanced CNC machines that help us to produce molds and prototypes faster.

- High Accuracy and Precision

The CNC machine for rapid tooling provides very accurate and precise molds for die casting prototypes. This goes a long way to help you get precise prototypes that meet your specifications.

As a professional aluminum die casting manufacturer in China, we have highly advanced CNC machines and cold chamber machines that help to produce excellent aluminum die casting prototypes efficiently.

Our DMU monoBLOCK 5 – axis CNC machine makes Sunrise very capable of producing highly precise tools with tight tolerance for die casting aluminum prototypes.

- Supports Complex Designs.

Sunrise’s 5 axis CNC machine supports highly complex designs. This helps us to produce very complex molds with ease for aluminum die casting while ensuring precision.

- Cost-Effective.

Since CNC machines produce molds for die casting quickly, it means you are not wasting much resources and labor.

Sunrise’s CNC machines can reduce your production time by up to fifty percent.

Which industries use aluminum die casting prototypes?

Aluminum die casting prototypes are used by a wide range of industries because of their accuracy, strength, lightweight, durability, corrosion resistance, etc.

Below are some of the top industries that use aluminum die casting prototypes.

- Automotive

- Medical

- Electronic

- Aerospace

- Military

- Telecommunication

- Marine

There are other general industries that use aluminum die casting prototypes for their products.

What Determines The Cost of Aluminum Die Casting Prototypes?

Many factors determine the cost of aluminum die casting prototypes. A good understanding of these factors will make the manufacturing of your aluminum die casting prototypes cost-effective.

Below are some of the important factors you need to consider:

Design.

The cost of your aluminum die casting prototype has a direct relationship with your design, especially when it comes to molds. The cost of CNC machine rapid tooling is tied to the design of your prototype mold. The simpler your prototype mold design, the better, and this reduces your cost.

Quantity

One crucial factor that affects the cost of your aluminum prototype is the quantity you produce.

You can contact Sunrise for advice on your prototype production cost based on your desired prototype quantity. We will be more than happy to give you professional advice to help make your production cost-effective.

Machinery

The type of machines used for producing aluminum die casting determines the cost of prototypes. Power used by machines like electricity, heat, etc. also affects the cost of aluminum die casting prototypes.

Material.

Material for producing aluminum die casting prototypes is another factor that affects your cost.

The type of material used for creating molds for die casting affects your production cost. So is the type of aluminum alloy you use for die casting.

The quantity of material needed for the aluminum die casting prototype and its unit price determines the cost of production. The quantity of materials required is also dependent on the part that is to be produced. When the part to be prototyped is determined, an estimated cost for production can be calculated.

Depending on your industry, your project goal, and other factors, Sunrise can help you choose the right materials for your prototypes. This will ensure both the quality of your prototype and your production cost-effective.

For CNC rapid prototyping, your choice of material affects both your cost and efficiency of your prototype. The material you choose also determines the type of technology for rapid prototyping. It is advisable to choose materials that don’t exceed your requirements.

Labor

Labor also determines the cost of aluminum die casting prototype production. This includes the salary of workers and the investment made to train them.

Are your Aluminum Die Casting Prototypes Precise and Accurate?

Yes, our aluminum die casting prototypes are precise and accurate. As a highly professional aluminum die casting manufacturer in China, we have invested in highly advanced equipment and technology that makes us capable to produce precise and accurate aluminum die casting prototypes.

Our DMU monoBLOCK 5 – axis CNC machine and 7 axis CNC machines with a tolerance of 0.005mm help us to manufacture highly precise molds with no room for error. These precise molds are used for die casting aluminum prototypes and they produce excellent results for our + 500 global clients.

Our highly equipped and efficient measurement instruments like a digital caliper, X-ray detector, spectrometer, cleaning test lab, Carl Zeiss CMM-with automatic scanning function, have a 0.001mm measuring precision. This helps us to take accurate measurements on all our die casting products, ensuring they are accurate and meet customer’s requirements.

Contact Sunrise Metal today, and experience highly precise and accurate aluminum die casting prototypes service.

How Do I Get a Quote for My Aluminum Die Casting Prototype?

It’s pretty very simple getting a quote from us. You first need to send us information on your product.

Kindly follow the steps below to understand how to send us a quote for your aluminum die casting prototype.

- Give us details about your aluminum die casting prototypes.

- Send us the volume of work or project. Part sizes and quantity can help us estimate the material required.

- Indicate to us if your project is required to be finished within a fixed period.

- Let us know the level of accuracy and finish you desire.

- Send us your model file. This will help us determine the level of difficulty of your project. You need not worry if you don’t have a ready model. Our competent engineers can help you with this.

You can contact our dedicated customer support for clarification if you don’t understand anything. They will be excited to help you.

What Factors Do You Put in Place to Ensure The Quality of Aluminum Die Casting Prototypes?

Quality is the least concern of our +500 global clients and you should have no worry about it if you come to work with us. Our high precision equipment, efficient measuring instruments, and effective manufacturing processes help us produce quality products for our clients.

As an ISO 9001 & IATF 16949 certified company, Sunrise has proven itself to have strong management systems that make us produce quality products that meet customer requirements and make them satisfied. You too can become a highly satisfied Sunrise customer today by doing business with us.

As China’s leading Aluminum die casting manufacturer, we follow strictly all international recommended standards during our manufacturing process.

Our ultimate aim is to produce perfect and fully functional products for our clients and that’s why we keep investing in highly advanced QA Test equipment.

Our QA team is trained, highly dedicated, and experienced. They monitor the quality of manufacturing from raw materials to finished products. Be rest assured of high-quality products when you work with us.

Do You Have Experience in Aluminum Die Casting Prototype Manufacturing?

Yes, Sunrise is very experienced in aluminum die casting prototype manufacturing. We have over 10 years of experience in aluminum die casting manufacturing.

Our engineering team of experts, competent toolmakers, and well-equipped QA team have seen it all. They have managed a wide range of aluminum die casting prototype projects with great success.

Our engineering manager has over 23 years of experience in aluminum die casting. This makes us highly competent to provide excellent aluminum die casting prototype services to you. We can suggest and guide you with the most economical solutions for your projects.

Why Should I Choose Sunrise Metal for My Aluminum Die Casting Prototypes?

Sunrise Metal has the capability to perfectly meet all your aluminum die casting prototype needs because of our highly advanced rapid prototyping facilities and aluminum die casting equipment.

+10 Experience

With over 10 years of experience in this industry, we use our rich and invaluable experience to continuously improve our services for our clients. You can count on us to use our experience in this industry to deliver the results you desire.

Half the Standard Lead Time

Our rapid prototyping machines can reduce lead-time up to fifty percent. Our highly advanced rapid tooling and die casting equipment help us to produce prototypes at a faster rate. We understand that time is money and we, therefore, capitalize on our efficient machines and experience to deliver services quickly while maintaining quality.

One-Stop Solution

Sunrise Metal’s multiple rapid tooling and die casting options make us provide a one-stop service for you. We can take care of your project from start to finish without worrying about external suppliers.

Capable Engineering team

As the leading aluminum die casting manufacturer in China, we have a capable engineering team that can help you design, produce, and controls the quality of your prototypes. We have 182 competent and skilled workers who are committed to helping you get excellent products that meet all your requirements

Highly Advanced Equipment

Our highly advanced equipment helps us to produce very precise and accurate aluminum die casting prototypes for our clients. We use the latest tech machines and measuring instruments in our manufacturing, which helps produce value-added quality products.