PROFESSIONAL CNC MACHINING MANUFACTURER IN CHINA

Sunrise Metals, as one of the professional CNC machining companies in China. With over 10 years of experience, we provide you with well-grounded Computerized Numerical Controlled (CNC) services by covering every area of CNC machining.

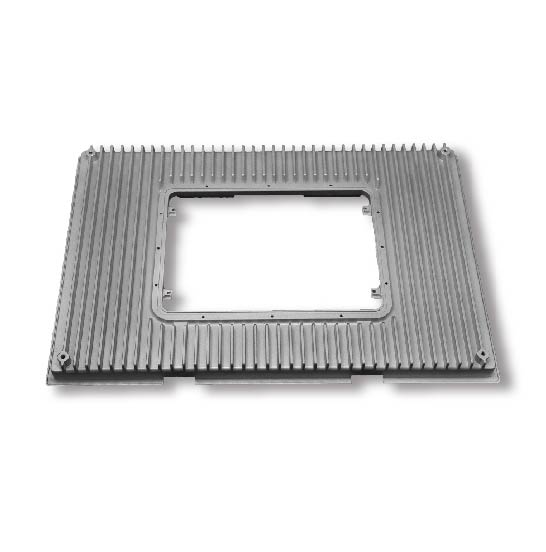

We specialize in providing you with CNC lathing, CNC drilling, CNC milling, CNC saw machining, and many other services for a complete solution. Our CNC machining services are precise and can be repeated over and over again. No matter what your requirement is, our competitive services will bring the best quality results for you no matter how intricate the design.

Reliable CNC machining services with high precision in China.

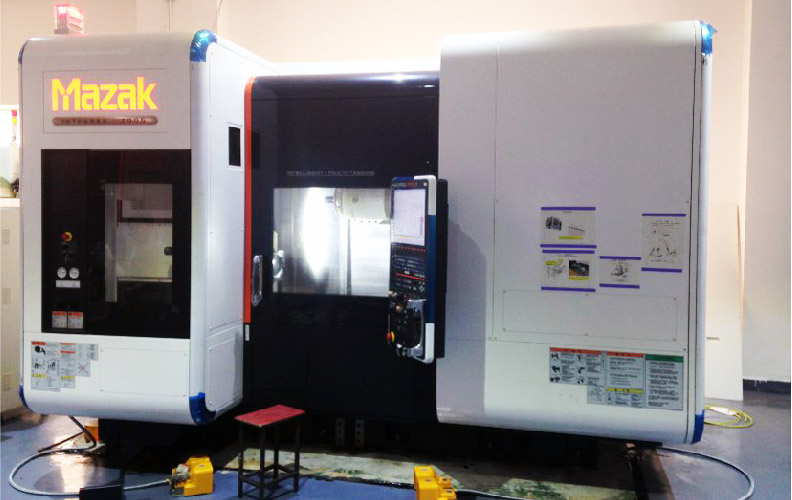

YOUR PERFECT PRECISION CNC MACHINING PARTS COMING FROM SUNRISE HIGH-END CNC MACHINING EQUIPMENT

GET CHINA'S MOST RELIABLE CNC MACHINING MANUFACTURER

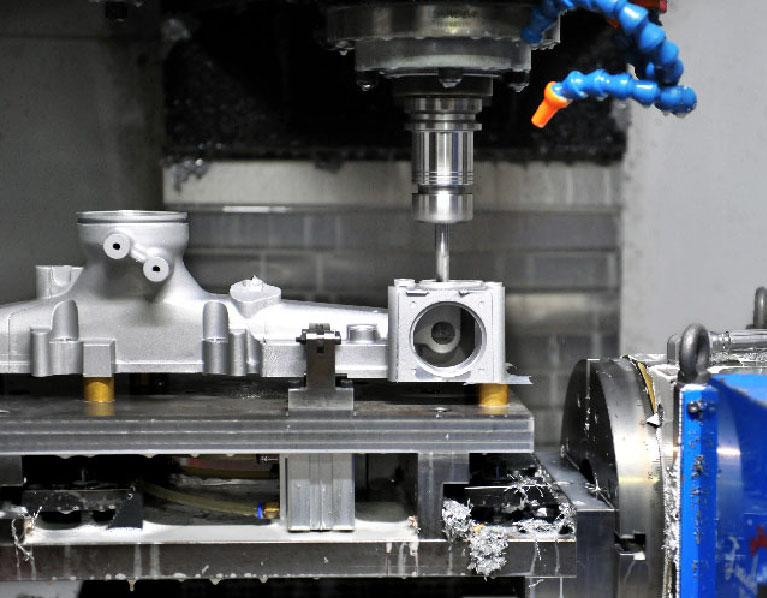

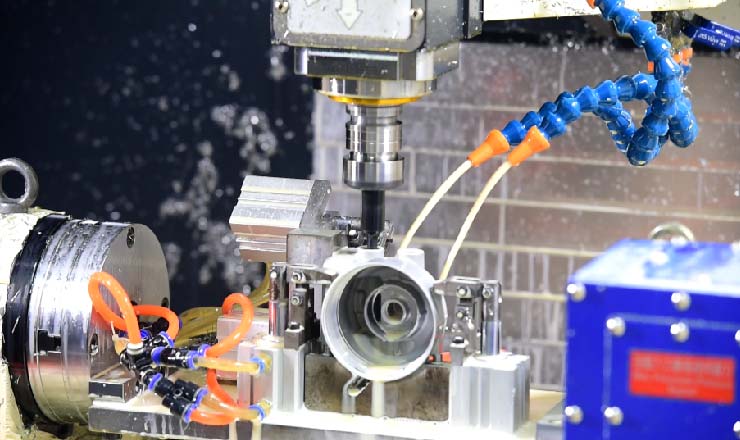

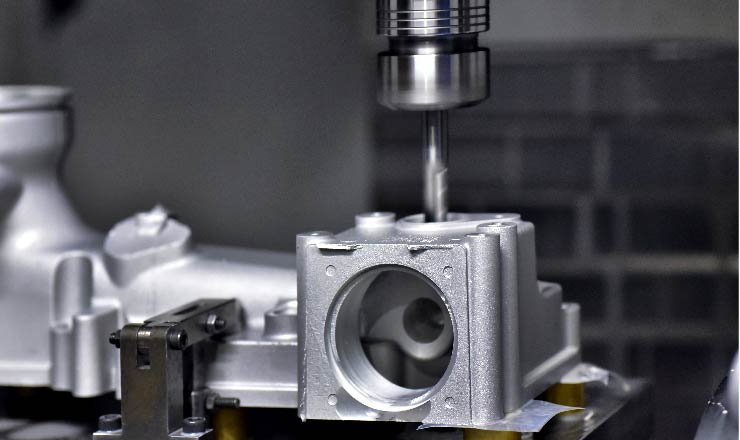

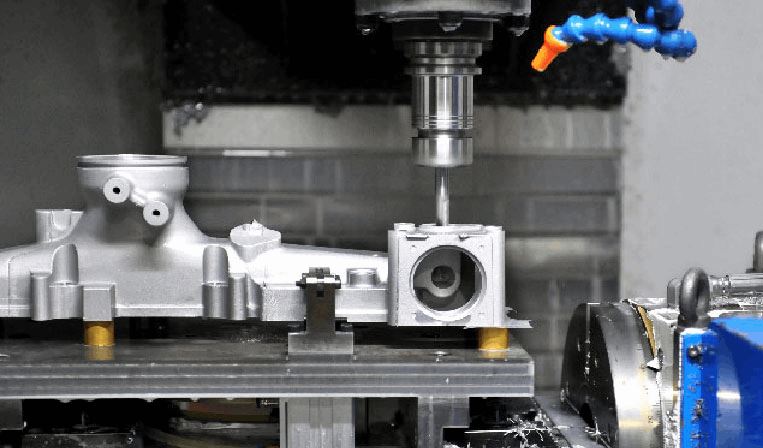

Sunrise Metals is equipped with 23 sets CNC Machining Center and 4 CNC Lathes that can help your metal part produce high performance. This allows us to machine not only die cast parts but also parts that are produced using forging, gravity casting, solid extrusion, etc. CNC machined parts are also manufactured in our dedicated facility to achieve guaranteed high-quality products.

Sunrise Metals is a major CNC machining manufacturer in China. Don’t settle for less and contact us to attain premium CNC machining and manufacturing services in China.

CNC precision machining manufacturer with CNC machines dedicatedly employed in die casting machinery.

Sunrise Metals provides superior CNC machining services in China. Our high-level resources allow us to meet your every requirement. Our capabilities include:

- Rapid Turnaround: Our latest CNC machines allow us to create even the most intricate designs in as fast as 3 days.

- High Scalability: Our CNC machining services allow us to produce as many products as we want with no compromise on quality

- Custom Finishing: Bring your designs to us. Our CNC machining services can help achieve accurate design specifications.

- High Precision: As a leading CNC precision machining manufacturer in China, Sunrise uses equipment that provides low tolerances on customer specifications. The tolerances range between +/- 0.05mm.

- Easy Repetition: Sunrise’ CNC machining services allow the production of your required part multiple times to attain the exact same copies of your specifications.

10000+ PRECISION CNC MACHINED PARTS MANUFACTURING EXPERIENCE FROM 500+GLOBAL CLIENTS

MANUFACTURING AND SUPPLYING CNC MACHINING PARTS FOR VIRTUALLY EVERY INDUSTRY

Sunrise is the CNC machining supplier of parts from almost every industry. This is because our machining services can work with every material possible. Your requirement can include aluminum, steel, iron, bronze, zinc, their alloys, and almost every metal available.

Our machining services can bring you precise results. Due to this factor, many industries heavily rely on our CNC machining services like industrial manufacturing, metalworking, aerospace, architecture, electronics energy, oil and gas, marine, military and defense, and medicine and healthcare.

- Advanced Precision CNC Machining Equipment

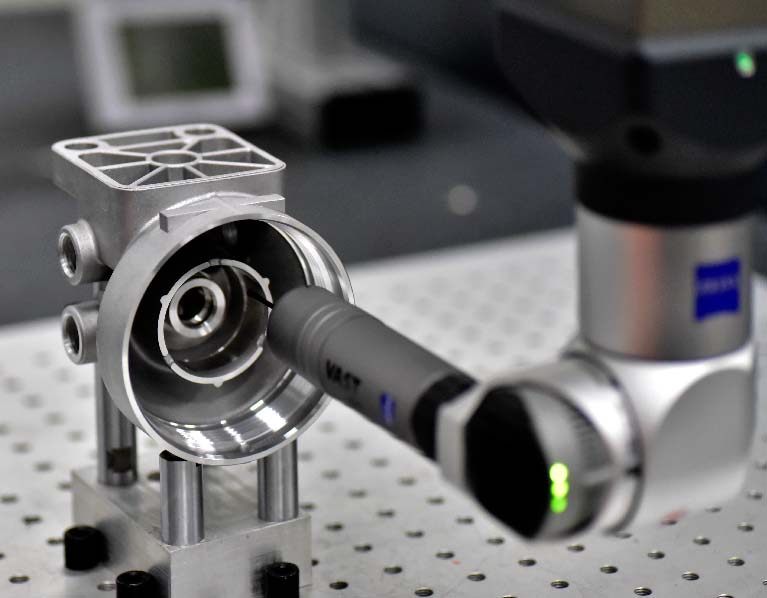

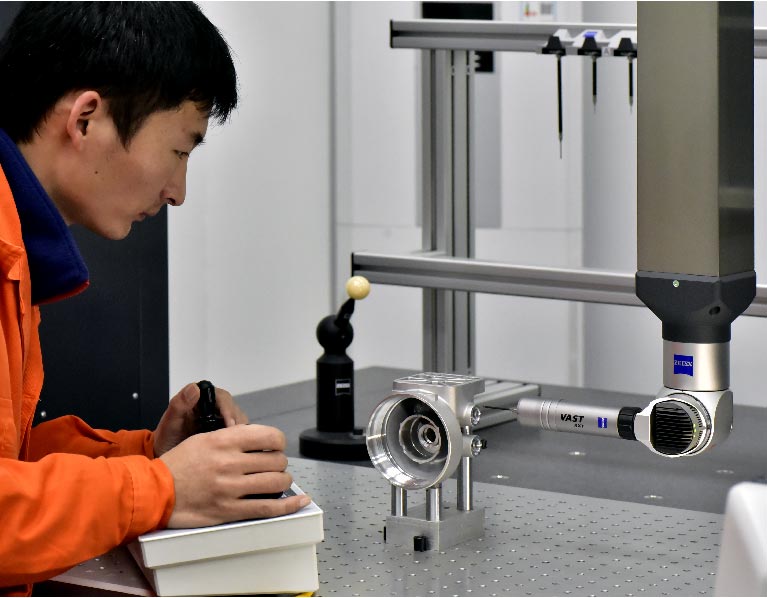

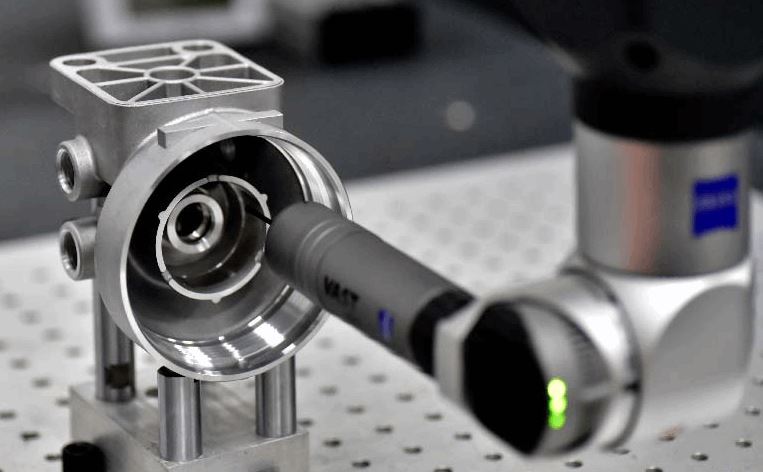

- Premium Quality Measuring Equipment

| No. | Name | Stroke | Q’ty |

| 1 | Mazak 7-axis turning&milling Machine | Ø658*1011MM | 1 |

| 2 | Mazak /Hass 5axis CNC machine | Ø850/Ø600 | 4 |

| 3 | 3-axis CNC machine center | 2000*1500MM | 1 |

| 4 | 4-axis CNC machine center | Ø250*800MM | 8 |

| 5 | 3-axis CNC machine center | 1000*600*600MM | 20 |

| 6 | CNC Lathes | Ø320*800/Ø610*1000MM | 2 |

| 7 | Sodick Wire cutting Machine | 400*400*200MM | 3 |

| 8 | EDM machine | 500*400*400MM | 2 |

| 9 | Surface grinder | 600*300*200MM | 1 |

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

THE CNC MACHINING SUPPLIER WITH COST-EFFECTIVE SOLUTIONS

As an accomplished CNC precision machining company in China, Sunrise Metals meets the customers’ low and high volume needs. We provide you with the most cost-effective solutions while keeping the quality and standards high. Our efficient processes ensure very little to no waste during production. We lay out the process and manage the CNC machining to ensure using every lot of material. This provides you with optimal cost and higher efficiency for your products.

Extremely accurate machining process with almost no waste.

Here is just a small part but the critical way that we’re serving you on CNC precision machining projects.

Sunrise Metal can offer full chain service if you have any needs on aluminum die casting projects. Looking learn more about aluminum die casting.

CNC MACHINING MANUFACTURER:

THE ULTIMATE FAQ GUIDE

Need the highest quality, strength, and accuracy for your products? Then you are probably looking for a CNC Machining Manufacturer. CNC machining has been one of the most popular methods for manufacturing metal parts.

It has become a preferred method of manufacturing for any sophisticated products. Sunrise Metal believes in quality and perfection. We are a leading CNC precision machining manufacturer in China that aims to achieve maximum customer satisfaction.

In this guide, I have discussed the common queries about CNC machining manufacturers in China and a few words about our company’s machining facilities.

- What is CNC Machining Manufacturing?

- How is CNC Machining Manufacturing Done?

- What are the Benefits of CNC Machining Manufacturing?

- What is the State of the China CNC Machining Market in the Global Economy?

- When Do I Need to Partner With a CNC Machining Vendor for My Project?

- What are the Primary CNC Precision Machining processes Used by the Manufacturers?

- Why do the CNC Machine’s Axis Matters for a Manufacturer?

- What is the Difference Between a CNC Machining and 3D Printing Manufacturer?

- What are the Common CNC Machines Available in China Machining Factories?

- What are the Important Design Factors for CNC Machining Manufacturer?

- What are the Most Used Aluminum Alloys in China CNC Machining Companies?

- What Should be the Qualities of a CNC Machining Company?

- How Do I Find a Good CNC Machining Supplier in China?

- Why Should I Choose Sunrise Metal as my CNC Machining Supplier?

- What CNC Machining Services are Offered by Sunrise Metal?

- What CNC Machining Equipment Does Sunrise Metal Have?

- What is the Best CNC Machining Tolerance Offered by Sunrise Metal?

- Can Sunrise Metal Make CNC Machined Prototypes For Me?

- What Materials Can be CNC Machined at Sunrise Metal?

- What is the Production Capacity of Sunrise Metal’s CNC Machining Facility?

- What is the Standard Lead Time of Sunrise Metal CNC Machining Services?

- How Can Sunrise Metal Guarantee the Quality of CNC Machining for My Project?

- What Industries does Sunrise Metal’s CNC Machining serve to?

What is CNC Machining Manufacturing?

CNC stands for Computer Numerical Control. CNC Machining is a computerized process of cutting a solid block of material to the required shape. A great advantage of CNC machined parts is that there is no chance of human errors during operation.

The cost of CNC Machining is pretty high. It is mainly preferred for manufacturing metal parts that have sophisticated applications. Nowadays, most of the big industries extensively use CNC precision machined parts for their products.

How is CNC Machining Manufacturing Done?

CNC Machining is an automated process. But the automation needs to be configured by programmers first. There are some steps involved before one can proceed with machining the parts. I have briefly discussed the whole process below.

3D Model Creation

Model Making is the first thing to do for any manufacturing process. You can create a 3d model of your parts using CAD software. Keep in mind the machining process while designing your parts. Certain types of geometric features can complicate the process and increase your machining cost.

Design for Manufacturing

Any product design needs to be optimized to make it suitable for machining. Some features in the original design may be tweaked a bit to suit the machining process. It is known as design for manufacturing of parts.

Assessing the Required Machining Processes

Before machining a part, the part’s design is analyzed thoroughly to determine the required machining processes. Some parts need milling, some turning, and some may require multiple types of tools. It depends on the geometric features of a part.

Choosing an Efficient Machining Order

A successful machining operation is dependent on many factors. The proper order of the machining processes can be one of them. Always try to arrange it in such a way that the machining needs minimum tool change. It can reduce machining time.

Programing the Machine Codes

When you are done with all the pre-assessment tasks, it’s time for some coding. Convert your final design into a machine-readable code using CAM software. The code contains the tool change sequence, tool movement, rotation speed, etc. commands.

Let the CNC Machine do its Job

Once you have the code ready, your job is almost done. Place a solid block of your desired material in the CNC Machine. Input your codes in it. Then sit back and relax as the CNC machine completes the task with minimum human interference.

What are the Benefits of CNC Machining Manufacturing?

CNC Machining has many benefits over other means of manufacturing. The leading Chinese manufacturing factories rely on CNC machining to manufacture high-quality parts. Some advantages of CNC Precision machining is described below.

Excellent Precision

The fact that CNC machining is often called CNC precision machining is because of its outstanding accuracy. It is by far one of the most precise manufacturing processes till now. When precision is your maximum priority, it is the way to go.

Enables Intricate Detailing

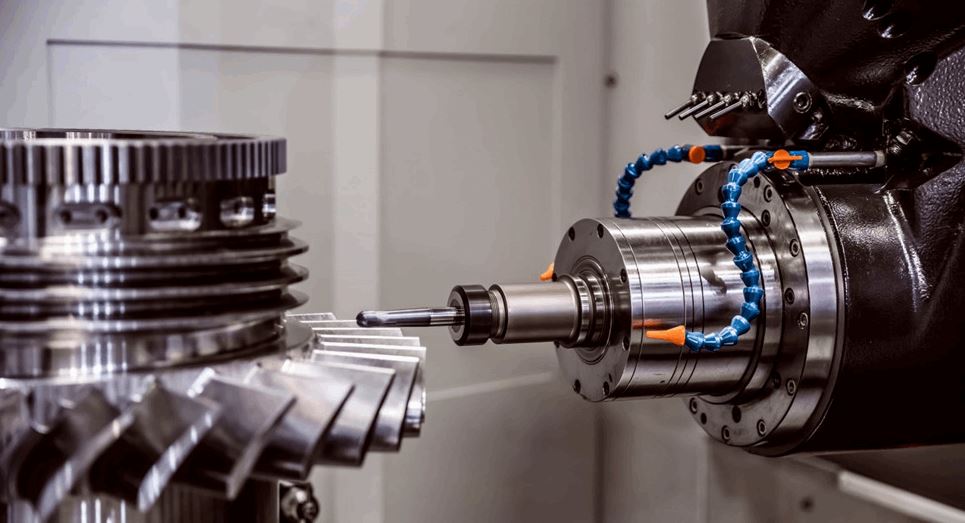

CNC Machines are capable of creating complex parts. Intricate details that were very difficult before can be easily achieved now by CNC Machining. However, the capabilities of a CNC machine can vary. CNC machines with more axes can handle more complex tasks.

Amazing Repeatability

CNC Machine is known for its repeatability. You can expect to get almost identical parts in the production cycle. Repeatability is a crucial factor for sophisticated applications such as automobiles and aircraft.

No Human Errors

Human errors are almost close to none with CNC Machining. Because the whole process is automated and requires minimal human interference. However, there can be some issues regarding programming. As long as the codes are accurate rest of the process will go smoothly.

Versatile Material Option

CNC machines can work with a wide range of materials. That makes it a great choice for prototyping. You can create prototypes with your desired material, maintaining the right material properties. It allows for running accurate tests as well.

Longer Operating Time

CNC Machines can operate for a very long period without any break. Since the machine is automated and works without human interaction, it can function all day and night. So, production capacity is increased too.

Work Safety

CNC Machining offers a hazard-free work environment. No human interaction is needed during machining. So, there are little chances of accidents happening during the process.

Less Waste

CNC Machining is very accurate. So, the chances of defective and inaccurate parts are very low. It drastically reduces the need for discarding parts during production. Even the scrap material can be recycled and utilized for the next production cycle.

What is the State of the China CNC Machining Market in the Global Economy?

Today the manufacturing industry holds a massive chunk of the global economy. The CNC precision machining manufacturers in China have played an important role in making it possible. China’s huge land and human resources are a major driver behind it.

CNC Precision Machining has become a top choice for quality parts rather quickly. Along with China, many developed countries also joined the trend of CNC machining. Now, most of the big industries rely on precision machined parts for their products.

The competition is very tense now, but the China CNC precision market still comfortably holds the number one position in the global market. China owns almost a 10% share of the global economy from the machining industry.

When Do I Need to Partner With a CNC Machining Vendor for My Project?

Do your products require parts with a high level of precision? Then yes, you need a CNC precision machining manufacturer for your project. CNC machining can offer the best dimensional accuracy for your parts.

All sophisticated devices and transportation mediums are somehow dependent on precision machined parts. The intricate details needed for such an application is hard to achieve using other manufacturing technologies.

When you are looking for the best, regardless of the costs involved, partnering with a CNC machining business would be the most viable choice.

What are the Primary CNC Precision Machining processes Used by the Manufacturers?

There are different types of CNC machines available in the market with varied specifications. But the operations performed by them falls under some specific categories. The primary CNC machining process is discussed below.

Milling

Milling is the most common CNC machining process. It involves cutting the workpiece using rotating tools that can move in multiple directions and axes. The tools can have different diameters and shapes, each suitable for a specific geometry.

CNC Milling process is classified into peripheral and face milling. Peripheral milling is used for deep pockets, threads, etc. In contrast, face milling is used to introduce cavities with a flat bottom.

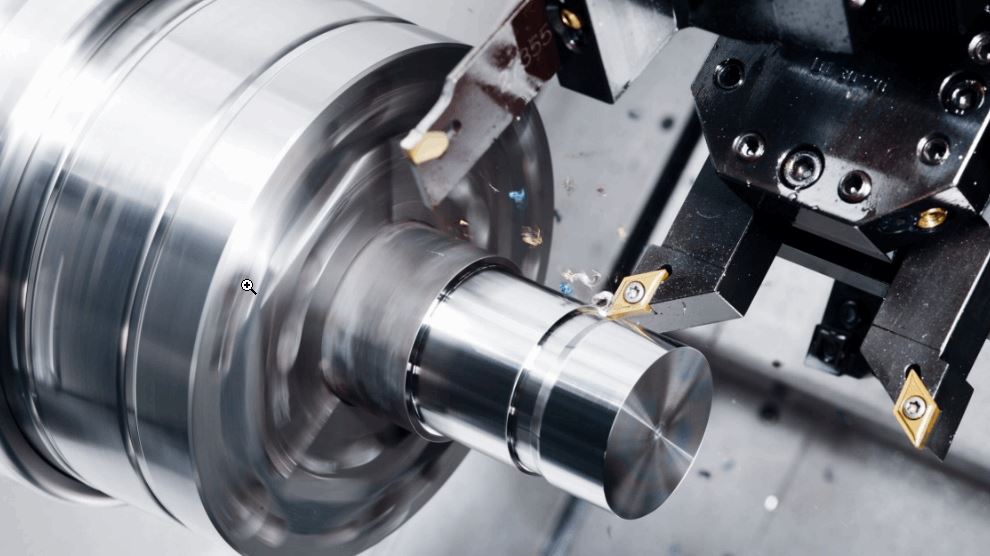

Turning

It is a convenient process for creating cylindrical parts with ease. The main difference between milling and turning is the rotating element. Unlike milling, the workpiece itself is rotated instead and moved against a tool in a linear direction. Turning is straightforward and faster compared to milling.

Drilling

Drilling is required for creating holes in a part. The tools used for drilling has a different structure than those used for milling and turning. The tools are called drill bits and have a helical shape around its periphery. Its shape allows the cut material to escape the hole. So, chips do not stack inside it.

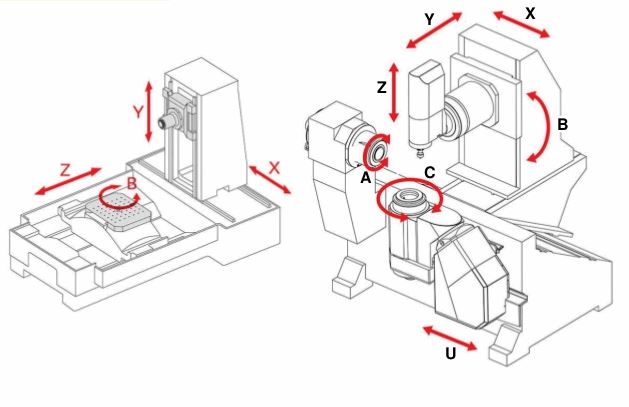

Why do the CNC Machine’s Axis Matters for a Manufacturer?

The axis is a parameter for CNC machines. You will find CNC machines with a varying number of axes available in the market. They usually range from 2 to 7 axes. The axis gives a relative measurement of the capacity of a CNC machine. As the number of axis goes up, their capabilities also increase.

The 3-axis machines are one of the most used CNC machining tools in the world. The workpiece remains stationary, and the cutting tool works on the XYZ plane in 3-axis machines. It is one of the best tools to perform any job like drilling holes, milling slots, or cutting sharp edges on metal components.

The 4-axis tool is quite similar to the 3-axis tool. The only difference is there will be one or more additional rotation with A-axis or B-axis, where both axes will be around X plane. It allows Intermittent cutting, Continuous cutting, and Engraving curved surface.

Similarly, the 5-axis machine has two additional degrees of freedom. It has higher quality finishing and maintains intricate details. And the 7-axis CNC machines are considered the best out of all. It has the highest movement capabilities that enable the completion of more complex tasks.

So, as we can see, the axis is a major determinant of the capabilities of a CNC machine. So, it is very important for any manufacturer.

What is the Difference Between a CNC Machining and 3D Printing Manufacturer?

CNC machining is a subtractive manufacturing process that works by removing material from a solid block of material. 3D printing, on the other hand, is an Additive Manufacturing process that works by building the parts from scratch layer by layer.

Both CNC Machining and 3D printing can create plastic and metal parts. But to the cost of 3D printing metal is relatively high. Plastic is mainly used for 3D printing due to its material properties. Their low melting temperatures make them a suitable material for 3d printing.

In contrast, CNC machining is mostly preferred for the production of metal parts. Aluminum is the most used material in terms of using CNC machining. Apart from Aluminum, Stainless Steel, Brass, Zinc, and Magnesium Alloys also exhibit excellent machinability.

CNC machining is considered a more complex and time-consuming task to complete compared to 3D printing. But it is all worth it considering the higher degree of precision, and mechanical strength achievable with CNC precision-machined metal parts.

But as always, both of them have their pros and cons. The client may choose CNC machining or 3D printing, depending on their project requirement and financial constrictions.

What are the Common CNC Machines Available in China Machining Factories?

CNC machining is an automated process. There are different types of CNC machining tools being used in China manufacturing companies. Based on the machining operations performed, CNC machining tools can be classified into different types.

CNC milling machines are the most versatile CNC equipment capable of used to cutting random shapes, slots, pockets, holes, etc. In this case, the workpiece is stationary, and the machining tools are rotated against it to remove material.

CNC lathe is mainly used to do cutting on cylindrical objects. It works in the opposite manner of milling machines. The workpiece is rotated against a stationary cutting tool in this case. There are some other types of machining tools such as CNC plasma cutters, CNC grinders, CNC drilling machines and etc.

CNC Machines can also be thought of as a point to point systems. Here both tools and materials are placed on a fixed point until the process is done, and then it retracts automatically. The opposite is a contouring system, which is a process where the machining tool operates along a contour.

CNC machines can be classified based on their number of axes too. Usually, CNC machines range from 2 to 7 axes.

What are the Important Design Factors for CNC Machining Manufacturer?

There are quite a lot of design factors that can affect the CNC machining process. These factors are crucial to any CNC precision machining manufacturer in China. Some of the important design factors of CNC machining is explained below.

Holes: The size of holes should be kept within the limits of what an end mill tool can handle. Otherwise, a bigger hole may require using a drill bit. Machining with an end mill is preferable over drill bits due to their ability to machine more geometric features such as slots and deep pockets. It saves the tool change time.

Cavities: The designer should carefully choose the cavity depth. Machining deeper cavities with a standard end mill tool are more challenging and requires more time. So, that will increase the machining cost for you.

Internal edges: Always provide fillets to all sharp edges. Outer edges are manageable, but inner edges are very hard to machine without high-precision tools. Also, keep the radius of internal fillets within limits specified by your supplier.

Thin wall: Machining creates stress in your parts. Thinner walls are prone to fail under this stress. That’s why thin walls are machined with more time and consideration. The minimum wall thickness you can safely provide can vary depending on the material you are machining.

Small and Intricate Features: Some components may require tools with high accuracy due to their size and geometry. Smaller parts with intricate details should be avoided if possible. They require more sophisticated machining tools. Giving a significant rise to the machining cost.

What are the Most Used Aluminum Alloys in China CNC Machining Companies?

Aluminum alloys are one of the most popular material choices for CNC machining. Alloys are a composition of metal with multiple elements that increase the strength of the base metal. Pure aluminum is a relatively soft material for CNC machining, so alloys of aluminum are used instead.

Some of the common aluminum alloys used in the China manufacturing plants are discussed below.

Aluminum 6061

It is one of the best and most popular Aluminum alloys all over the world, including China. It has vast applications not limited to aircraft parts, boats or yacht. It has good tensile strength for what it can be easily used for any general-purpose CNC machining. Also, it has got good weldability and is resistant to corrosion.

Aluminum 6063

It is also another suitable metal to perform CNC machining. It is also easily weldable, but you should keep a certain heat treatment so that it does not lose its strength. It is good for frames of windows or doors. Also, we can give shape to furniture or tubes from this Aluminum properties with the help of CNC machining.

Aluminum 5052

It is another good material property for CNC machining. It is used in many Chinese machining shops. It can be easily bent or punched. But it has got a higher resistivity to corrosion. It is suitable for aircrafts parts, home appliances, panels and etc.

There are few more Aluminum alloys like Aluminum 7075 and others available in China. Each of them has different properties and have a specific field of application.

What Should be the Qualities of a CNC Machining Company?

There are various qualities that a good CNC machining company should have. Machine capability and availability of various CNC machining tools are the most important thing for any CNC precision machining business in China.

- A good CNC machining company should have skilled and expert engineers in their company. Without professionalism, a company can never achieve the best result. So, it is mandatory to have a good number of engineering expertise.

- Experience is a must when it comes to performing CNC machining. Though CNC machining is a relatively new thing but still, having experience of decades can be a good sign of a good and established CNC machining company.

- Communication skill is a crucial part of any good CNC company. Without proper communication with the clients, the end product may fail to meet the requirements of the client properly.

- Having a strong command of English is important for any Chinese company. It helps them reach out to foreign clients more effectively.

- Good customer services are the key point for a CNC machining company. To get familiar as a good company, one must provide the best supports to their clients and gain their trust.

All in all, a good CNC company will offer you the best suggestion and also will give you advice on how you can improve your design part’s design.

How Do I Find a Good CNC Machining Supplier in China?

Nowadays, CNC machining is an essential manufacturing process, and it can be widely found all over the world. Yet, China holds the number one spot for CNC machining manufacturers. Every day a new CNC machining manufacturer is showing up in the competitive CNC market. So, it is necessary to identify the best CNC machining manufacturer.

Since China has got numerous numbers of CNC machining manufacturers, you should look for the quality on the first hand. Not all the companies have got the same quality work reputation, for what it is mandatory to identify the best company that never compromise with quality.

Generally, an old company can be taken into consideration in this part as the old one surely survived so long, depending on their goodwill. You should also check if they have got a quality control system department. Look for their machining equipment and engineering expertise.

Then let’s come to the price range. You can easily find the best deal for your work. If you look for a few companies, you can definitely find the best deal with the best quality work. For the price range, .you can easily search on the internet to find the best affordable price for your machining needs.

Customer services matter the most when it comes to CNC machining. If they provide good support even after delivering the product, it is a sign of a good CNC manufacturer.

Why Should I Choose Sunrise Metal as my CNC Machining Supplier?

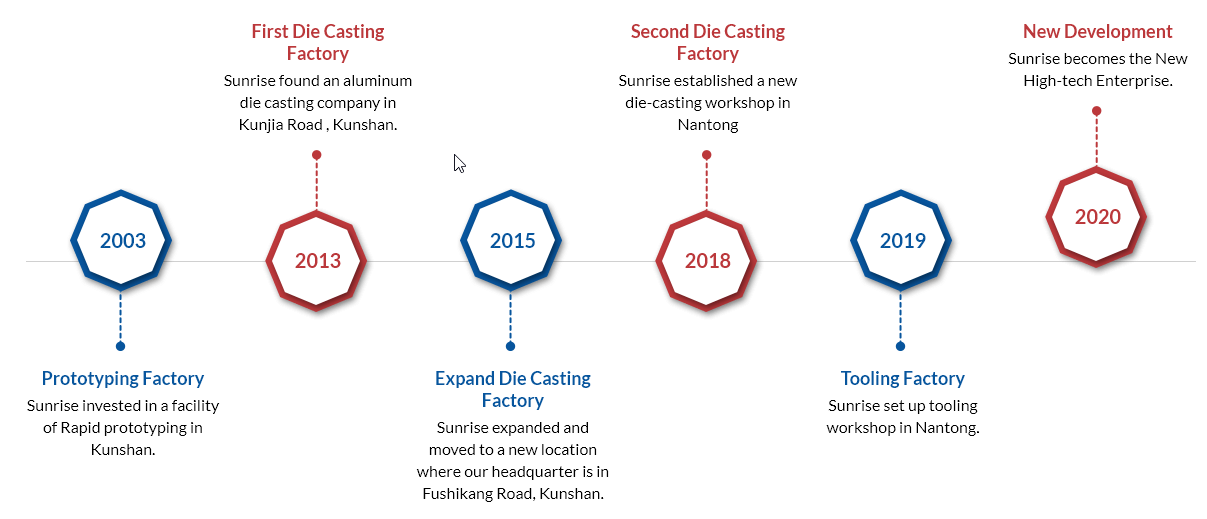

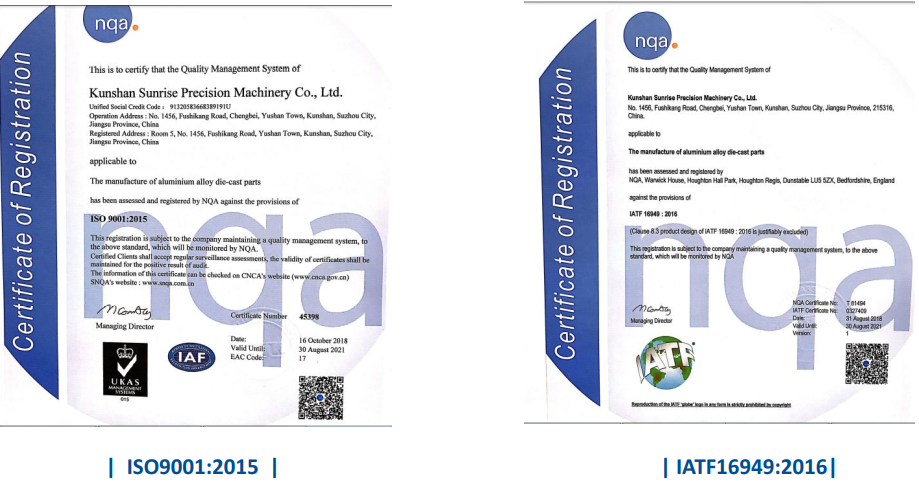

Sunrise Metal is a professional CNC precision machining supplier in China. We are an ISO9001 & IATF 16949 certified company with more than 10 years of experience in CNC machining. I have enlisted our CNC machining capabilities to help you understand how we can help you with your project.

Dedicated Machining Shop

Our company has a total of four manufacturing facilities. Out of them, two of the factories are dedicated to machining prototypes and die casting tools. Both of the facilities are fully equipped with advanced CNC machines.

Superior Logistic Support

Our company features one of the best logistic support in China. Our expert engineers and designers can provide the most economical solution for your project. We prioritize each of our customers differently and try to find the most efficient way to handle your project.

Multi-Axis CNC Machines

All of our machining equipment can operate in multiple axes. So, our production capacity is much higher due to faster machining and little to none errors. They also enable us to handle complex machining jobs as well. Our 5-axis and 7-axis CNC machines should be a good enough demonstration of our capabilities.

Strict Quality Management

Quality control of any project is equally important, if not more, than the production itself. Sunrise Metal doesn’t like to compromise with the quality. We make a significant investment in our quality management system to ensure flawless parts.

What CNC Machining Services are Offered by Sunrise Metal?

Sunrise Metal’s advanced CNC machining capabilities allow us to offer different types of services. This is something that makes us stand out from other CNC machining manufacturers in China. Here I have explained our CNC machining services in detail.

Rapid Prototyping

Prototyping is a crucial part of product development. Traditional prototyping approaches are time consuming and inefficient. Our high-speed CNC machining services can greatly boost your production capacity while ensuring maximum quality.

We also offer a wide range of materials for you. So, you are not limited to a few options. You can choose the one that best fits your project requirements. It will hopefully help you get better test results out of your prototypes.

Rapid Tooling

Die Casting Tooling is a major determinant of the outcome of your product. Our superior mold machining technology shall offer you the best quality parts. We even have a CNC machine shop dedicated to providing rapid tooling services.

Our designers, engineers, and staffs are all well trained and experienced to ensure the highest level of customer support. Our coordinated working approach helps us achieve shorter lead time and reduced production costs.

Precision Machining

When you have a low to medium volume project at hand, machining your parts might be the best solution for you. Sunrise metal’s enriched machining facilities can handle any project regardless of the difficulty and volume.

We have extensive knowledge and experience in machining. We continuously strive to increase our capabilities to provide you better service.

What CNC Machining Equipment Does Sunrise Metal Have?

Sunrise metal is a professional machining company equipped with all sorts of latest CNC machines. So, we are capable of handling diverse machining projects. I am sharing some details about the type of machining tools we use.

Machine Center: CNC machining center has higher workability enabling it to perform various operations. With the help of an automatic tool changer, it can perform any machining task more conveniently. To boost Sunrise Metal’s production capacity, we have about 23 sets of machining centers.

Milling Machine: Sunrise Metal has almost every CNC machining tools in house ranging from 3-axis to 7-axis. With the help of all these tools, we can do all works precisely and also with an economical rate. It can also work with the machining center too.

Lathes: Sunrise Metal has 4 dedicated CNC lathes machines. They are used to manufacture turning operations. It is used for machining parts with cylindrical geometry. It is significantly faster compared to milling machines.

Electrical Discharge Machine: Basically, EDM is used for hard metals that are tough to machine with other CNC machines. It operates by eroding metal parts with electrical sparks. Sunrise has two EDM machines at the machining shop.

Surface Grinder: Surface grinder is used to improve the surface texture of a product. It has a grinding wheel that spins and mechanically brushes the workpiece at high speed. We also have surface grinders that we use for finishing purposes.

What is the Best CNC Machining Tolerance Offered by Sunrise Metal?

Sunrise Metal provides first-class machining service with excellent tolerances. The maximum tolerance achievable by a CNC machine can vary based on its specifications. Most of our CNC machines are capable of maintaining a tolerance up to 0.005 inches.

The more advanced machines at our shop can offer an extreme level of precision up to 0.0002 inches. If you try to visualize these values, it seems almost unreal. But some sophisticated applications require such precision for the parts.

The best CNC machine at our shop is the 5 and 7 axis machine. They feature the best workability and tolerances to date. CNC machining for surface finishing purpose can achieve tolerances more than 0.0005 inches.

We also have sophisticated measuring devices to check our Machined parts. They can evaluate your parts with an accuracy of up to 0.00004 inches.

Can Sunrise Metal Make CNC Machined Prototypes For Me?

Yes, Sunrise Metal has the necessary equipment and logistic facilities available for prototyping products. We are one of the best prototyping shops in China. You can count on us for high-quality prototypes and faster delivery.

Our rapid prototyping technology enables us to create prototypes much faster without sacrificing quality. You can expect to achieve accuracy almost similar to the final product. So, you can get more accurate test results from the prototypes.

What Materials Can be CNC Machined at Sunrise Metal?

Sunrise Metal supports the machining of a wide variety of materials. Material availability is important for any product designer, OEM/ODMs. They have a need for testing prototypes made of different materials to find out which gives the best performance.

So, we like to keep more options available to our customers. We support most of the ferrous and non-ferrous metals along with a wide variety of plastics.

Some of the popular metals supported by us are,

- Aluminum

- Zinc

- Magnesium

- Stainless Steel

- Copper

- Brass, etc.

Some of the available plastic materials include,

- PC

- ABS

- Nylon

- PP

- PMMA, etc.

We shall also try to cooperate with your request to use other materials as well. We shall assess the feasibility and suitability of that material and help you out.

What is the Production Capacity of Sunrise Metal’s CNC Machining Facility?

Sunrise Metal can efficiently handle any low to medium volume projects with ease. Unlike other big suppliers, we shall accept any low volume, high mix project as well. You can count on us for any sort of CNC machining services required for your project.

We accept CNC machining orders ranging from 1 to 200+ pieces. So the quantity of your project is not a problem. With our vast machining capabilities, we shall complete your project on time.

What is the Standard Lead Time of Sunrise Metal CNC Machining Services?

Time is a very important issue for any CNC machining manufacturer in China. The cost of machining is mainly calculated based on the operating hours. At Sunrise Metal, we adopt some unique measures to reduce the lead time for machining.

Our expert engineers are able to optimize your design to reduce the number of machining operations required. Normally CNC Prototyping of parts up to 200 pieces should take us only 1 to 2 weeks to complete.

CNC mold machining is a bit more lengthy process involving a lot of analytical processes. Still, it is usually done within the course of 2 to 4 weeks. Our rapid manufacturing techniques allow us to significantly reduce the standard lead time and boost your production.

How Can Sunrise Metal Guarantee the Quality of CNC Machining for My Project?

We pride on our CNC machining capabilities and hope to give you the best service. But what is the validation of our claim? I have explained some key points about our CNC machining services that should demonstrate our ability to uphold the quality of our work.

Multi-Axis CNC Machines

We have various multi-axis machining centers running on the latest technology. Our machining shops are equipped with more than 23, 3 & 4-Axis machine centers. The automatic tool change increases our work efficiency and reduces the chances of errors during a manual tool change.

We have the latest Mazak 7-axis and Hass 5-axis CNC machines too. They are ultra-precise machines with versatile movement along multiple axes. So, we can confidently guarantee the quality of the parts we machine.

Extensive Experience in Machining

We have a long history of working with CNC machines. We started our journey with a Rapid Prototyping factory back in 2003. Through years of hard work and the help of our R&D facilities, we have refined our machining methods to the finest. We are always trying our best to find innovative production approaches that best suit your project.

Compliant with International Quality Standards

Our CNC machining facilities are compliant with the international standards of quality control. The ISO 9001 certification declares the efficiency of our quality management system and hazard-free work environment. The IATF 16949 certification shows our proficiency in machining for the automotive industry.

Advanced Inspection Instruments

We are always investing in our quality management system. Because quality control is the key to a successful project. Some of our advanced inspection tools include CMM, X-ray detector, spectrometer, etc. These instruments allow us to avoid any unwanted defects or dimensional errors in our machined parts.

What Industries does Sunrise Metal’s CNC Machining serve to?

Sunrise Metal has worked with many companies belonging to different industries. So, we have enhanced knowledge of machining parts for some specific industries. Our contribution to some of the major industries is discussed below.

Automotive

We have machined many automobile parts for companies from all over the world. We are even recognized by the International Automotive Task Force (IATF) for an advanced quality management system for the production of automotive parts.

Marine

Our machining shops successfully manufactured numerous die-casting molds for marine parts. We have machined prototypes with marine applications too. We use corrosion-resistant material, and special machining approaches for marine parts to extend durability.

Medical

Precision parts play an essential role in the medical industry. It is of utmost importance to ensure perfect precision and endurance for the small the intricate parts used in medical devices. As a CNC precision machining manufacturing company, we can meet these conditions with our advanced machining facilities.

Telecom

Most telecommunication devices need tiny and complex parts. Carefully machined heat pipes are also a crucial part of telecommunication devices. We have extensive experience in machining telecommunication device parts. We have helped many companies with machining molds for their parts too.

These are just to give you an idea about our experience in CNC machining. We also machined parts for other industries and manufactured numerous general-purpose products.