PROFESSIONAL RAPID MANUFACTURING SERVICE IN CHINA

- Offer one-stop fast solutions including rapid prototyping, rapid tooling, and rapid production for mass production simplify the rapid manufacturing definition.

- Rapid tooling and rapid prototyping reduce the time-to-market of parts through its competitiveness, enhancing technologies.

- Provide rapid manufacturing services with rich experience in various industries to support your product development needs.

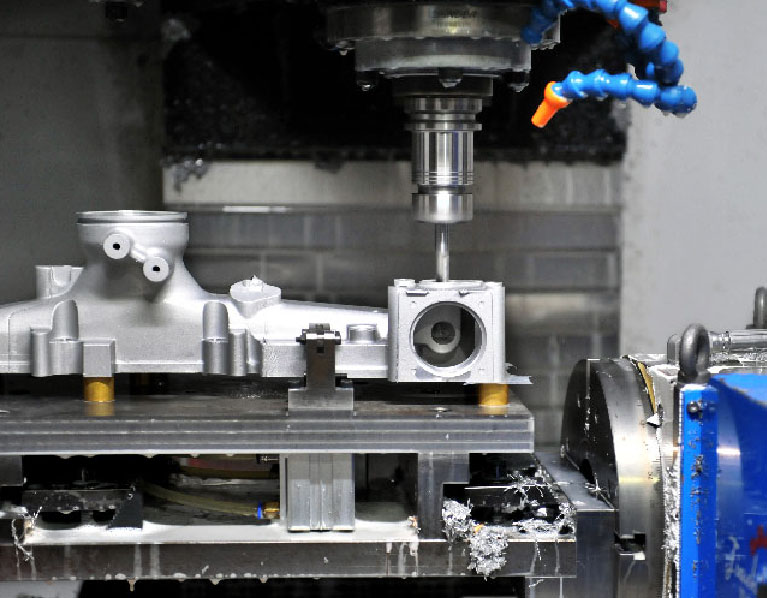

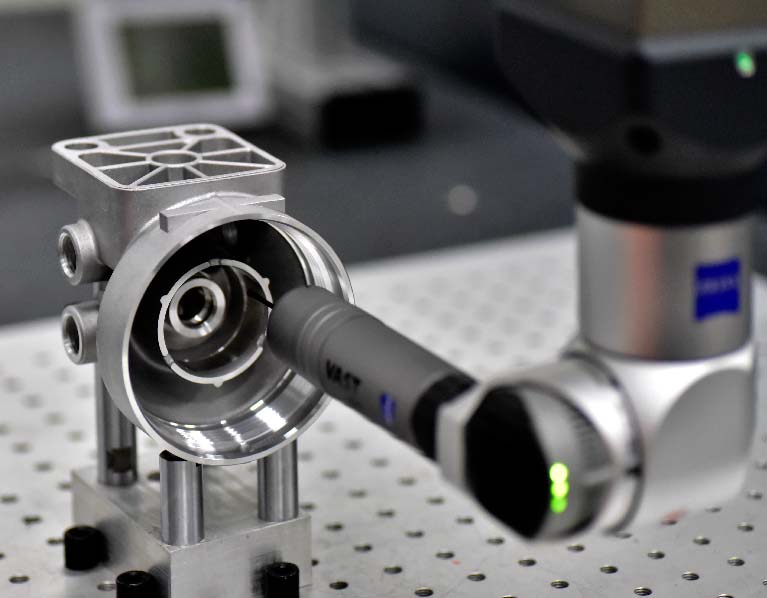

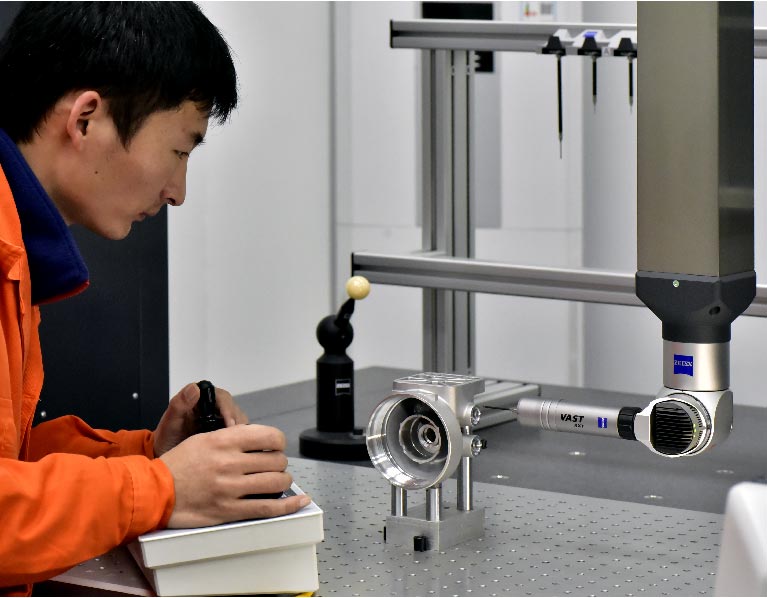

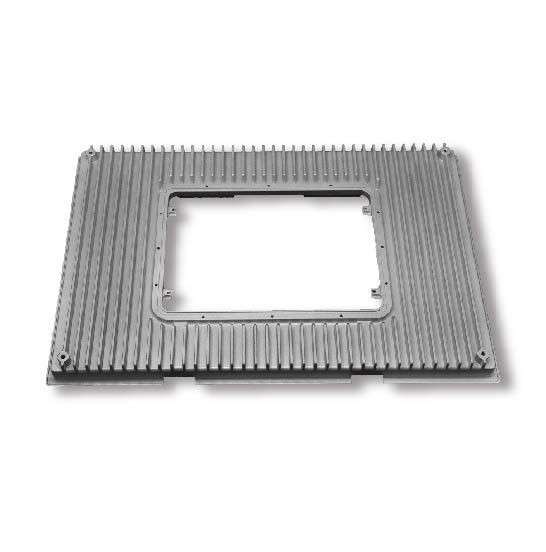

TOP CNC PRECISION MACHINING PARTS WITH SUNRISE HIGH-END MEASURING EQUIPMENT

HELPING YOUR PROJECTS SUCCEED WITH SUNRISE FULL CAPABILITY

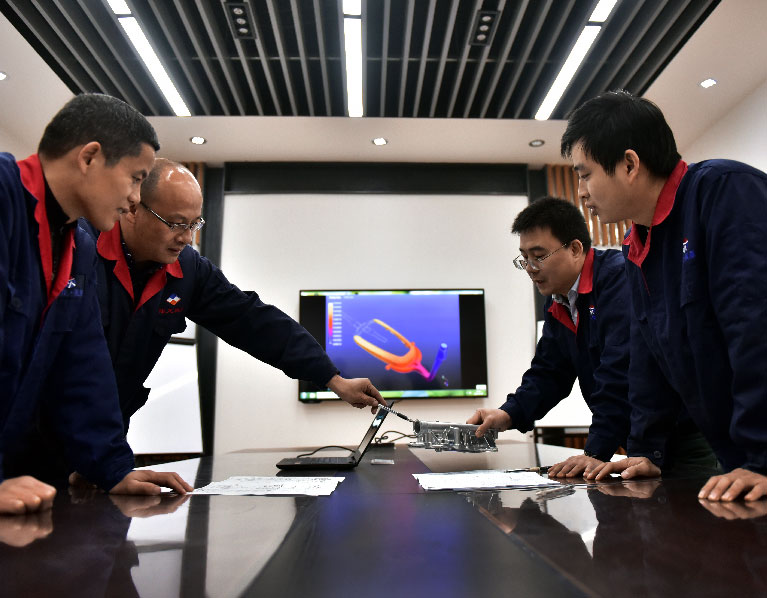

Our engineering team reviews the basics of your requirements and leaves no room for error when developing the required prototypes.

We meet global standards and customer requirements in terms of quality. We continuously improve our processes to meet the unique and complex needs of our customers and provide them with custom solutions. Our commitment to quality is shown through our ISO 9001 certification and the quality system work of our team.

10000+ PROTOTYPING PARTS MANUFACTURING EXPERIENCE FROM 500+ GLOBAL CLENTS

HIGH-ACCURATE & FUNCTIONAL FAST MANUFACTURING

While preparing orders based on customer requests and specifications, we focus on: Core functionality & Visual appeal & Mechanical characteristics. This will bring you Excellent product finish & Cost-saving process & Faster turnaround time.

- Advanced Prototyping Machining Equipment

- Good Quality Measuring Equipment

| No. | Name | Stroke | Q’ty |

| 1 | Mazak 7-axis turning&milling Machine | Ø658*1011MM | 1 |

| 2 | Mazak /Hass 5axis CNC machine | Ø850/Ø600 | 4 |

| 3 | 3-axis CNC machine center | 2000*1500MM | 1 |

| 4 | 4-axis CNC machine center | Ø250*800MM | 8 |

| 5 | 3-axis CNC machine center | 1000*600*600MM | 20 |

| 6 | CNC Lathes | Ø320*800/Ø610*1000MM | 2 |

| 7 | Sodick Wire cutting Machine | 400*400*200MM | 3 |

| 8 | EDM machine | 500*400*400MM | 2 |

| 9 | Surface grinder | 600*300*200MM | 1 |

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

GET A FREE CONSULTATION

Rapid manufacturing services at Sunrise make effective and efficient use of our resources to create masterpieces for your projects.

Skillful engineering consultants for prototyping parts. Specialized and project relevant advice will be based on your CAD and Step drawings.

Here is just a small part but an important way that we’re serving you on rapid manufacturing projects.

Sunrise Metal can offer full chain service if you have any needs for aluminum die casting. Looking learn more about aluminum die casting.

RAPID MANUFACTURING: THE ULTIMATE FAQ GUIDE

Rapid manufacturing is a new area of fabricating parts and prototypes using advanced technologies. Rapid manufacturing processes can improve parts quality and reduce development time.

This form of fast fabrication can be proven incredibly cost-effective, and its processes are far more flexible than conventional manufacturing.

Rapid prototyping, rapid tooling, and rapid production for mass production simplify the rapid manufacturing definition. It means all the processes are fast during production.

Rapid tooling and rapid prototyping reduce the time-to-market of parts through its competitiveness, enhancing technologies.

At Sunrise Metal, we offer rapid manufacturing services from China to support your product development needs. With our knowledge, experience, state-of-the-art technology, and material choices, the customers can fabricate everything with Sunrise Metal by their side.

- What is Rapid Manufacturing?

- What materials are suitable for Rapid Manufacturing?

- What is Rapid Manufacturing compared to Rapid Prototyping?

- What is the Rapid Manufacturing Process?

- How to choose the best Rapid Manufacturing Process?

- What are the benefits of Rapid Manufacturing?

- What is the connection between Rapid Tooling, Rapid Manufacturing, and Rapid Prototyping?

- Is Rapid Prototyping an essential part of the Product Development Process?

- Is Rapid Prototyping the same as 3D printing?

- Which is the best Rapid Manufacturing Process?

- What are the five objectives of Rapid Manufacturing?

- How precisely does Rapid Manufacturing can reach?

- What are the different applications of Rapid Production Parts?

- What are the benefits of Rapid Production Tooling?

- What is Metal Prototyping?

- Why make Metal Prototypes instead of Plastic Prototypes?

- What surface treatments do Rapid Manufacturing Companies use?

- How to Get Quality Fast Fabrication Service?

- How to make Rapid Manufacturing faster?

What is Rapid Manufacturing?

Rapid manufacturing uses software automation with connected fabrication equipment to rapidly accelerate the part and prototype manufacturing process.

Furthermore, rapid manufacturing is mostly on demand, low-volume production of injection-molded parts. These necessary parts can be of aluminum. However, this fast manufacturing automation is mostly applied to CNC machining, 3D printing, and more.

What it can do for customers is that the customers can have quality aluminum parts within a few weeks. Doing so also can reduce production issues and saves overall production costs. The customers can reduce product development cycles, decrease technical and supply chain risks, and minimize inventory and development costs.

The material selection, part geometry, and cosmetic requirements are the most important considerations to look at for all rapid-manufacturing processes. Quicker prototyping gave its customers an edge that no one can deny. These advantages are by no means limited to one domain.

The intensified speed and heightened accuracy our customers can achieve through rapid manufacturing are exceptional. The rapid fabrication techniques solve the problems related to complex-shaped parts. Rapid manufacturing technology always guarantees that it is the quickest way to part fabrication.

What materials are suitable for Rapid Manufacturing?

The materials for rapid manufacturing are incredibly diverse. The traditional metals are aluminum, and plastics, ceramics, and glass are secondary. Previously, a significant amount of new rapid manufacturing materials is introduced. UV-curing sol-gel has found its way into the market recently. These new rapid manufacturing materials are preferred to fabricate micro components and systems for large parts in parallel. However, aluminum is the most common rapid manufacturing material with the most benefits to offer.

Besides, the effective use of rapid manufacturing materials creates a different large amount of options for different clients worldwide. This’s required to produce parts rapidly and precisely according to the existing part specifications and requirements at low costs. Photopolymers are also used in rapid manufacturing, especially for optical, medical, and other related applications. For the majority of parts today, metal parts made by rapid manufacturing processes are being preferred to make injection molds.

These technologies can offer prime time and monetary savings and provide part functionality, which would be impossible to obtain otherwise. Sunrise Metal uses various aluminum prototype manufacturing alloys based on the required parts by customers. The different rapid manufacturing services of Sunrise Metal also fabricate different aluminum parts.

We prefer aluminum as a rapid manufacturing material because of its practical use in almost everything. It’s mostly useful from the auto industry to all sorts of medical, industrial, and consumer products.

In most cases, these parts must be durable, and that’s why they need extensive functional testing. Aluminum alloys are completely machinable and typically offer exceptional surface finishes.

New rapid manufacturing materials are being continuously developed, with better precision, accuracy, and final required production material specifications.

What is Rapid Manufacturing compared to Rapid Prototyping?

Compared to rapid-prototyping, rapid-manufacturing does not only fabricate prototypes; however, parts that are intended for use in real environments. With the assistance of different additive rapid-manufacturing processes, high-resolution 3D parts are manufactured legitimately from the existing CAD data.

Because of the different possibilities with respect to rapid-manufacturing materials, it’s possible to change the parts’ mechanical properties as required. The parts’ functionality can be widely tested along these lines. Furthermore, necessary tests related to the final product can be achieved through proper tests.

Rapid manufacturing is much more precise and outputs accurate results. However, rapid prototyping is one of the applications that utilize 3D printing technology to make new parts.

There are also four significant differences between rapid manufacturing and rapid prototyping:

Price: There is a big difference between the prices of rapid manufacturing and rapid prototyping. Materials, machines, labor, system maintenance are a few of the factors that affect the price of them both. Rapid prototyping is a bit expensive and can cost twice as much as rapid manufacturing.

The fabrication method’s complexity: Using rapid manufacturing is not difficult and requires extremely minimum training. However, it’s entirely depended on the part’s complexity.

With rapid prototyping, the parameters are almost as simple to adjust as it looks.

Material selection: The list of materials for rapid manufacturing and rapid prototyping are advancing. However, rapid manufacturing materials are limited as compared to rapid prototyping.

Level of accuracy: When it comes to precision, rapid prototyping can fabricate accurate and better finishes. However, both have similar features, such as the parts’ size based on a more considerable degree of geometry available. Sunrise Metal is experienced in developing prototypes that are as close to our customer requirements as could reasonably be expected.

What is the Rapid Manufacturing Process?

Using rapid manufacturing to fabricate your parts can help you get your parts to market quicker than your competition.

Modifications in part’s material, size, shape, design, color, manufacturability, and strength can be finalized after final prototype testing and analysis. To achieve this on time, you need to adopt rapid manufacturing.

Various rapid manufacturing processes are accessible to today’s clients. Some of these processes use traditional manufacturing techniques to produce parts, while different technologies have more recently been introduced.

CNC machining and sheet metal manufacturing (SMM) are frequently used in rapid manufacturing processes. However, we are going to take a closer look at them.

CNC Machining: The required part is produced using numerically controlled milling/drilling machines. This method is used in CNC machining when functional parts are required but for low volume production.

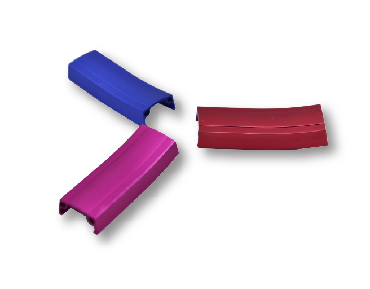

Sheet Metal Manufacturing (SMM): In sheet metal manufacturing, metal sheets are processed by folding, cutting, or other related processes. This process produces parts mostly made of aluminum and steel. These parts can be of various thicknesses, sizes, and shapes.

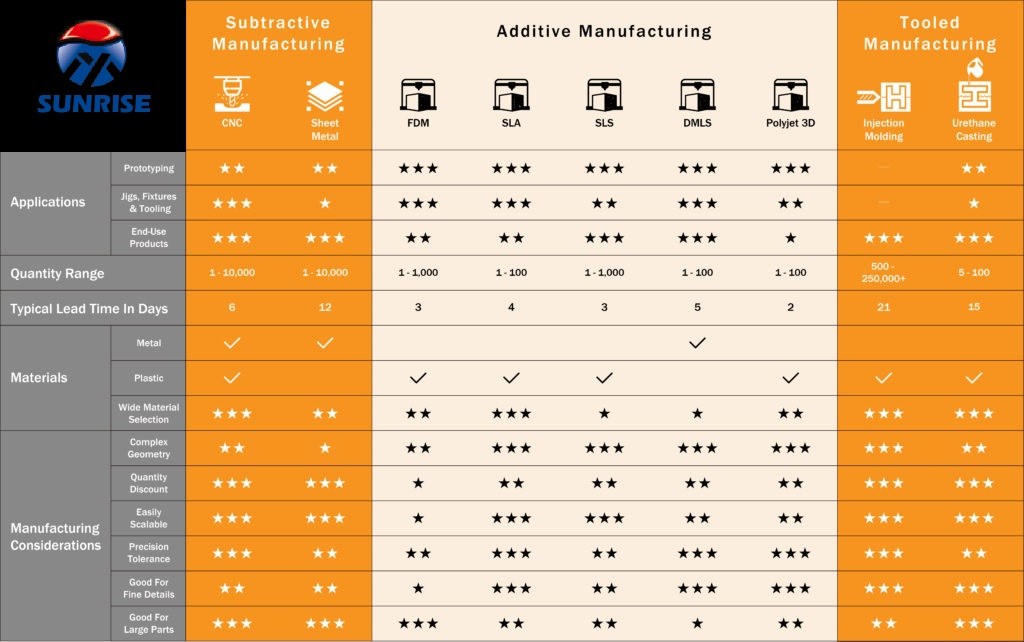

How to choose the best Rapid Manufacturing Process?

Adopting the rapid manufacturing processes to fabricate parts helps customers market their parts quickly and cost-effectively.

The results through rapid prototyping enable the engineers to test and analyze the design at the early stages. Doing so helps make the adjustments in design, materials, size, shape, assembly, color, manufacturability, and strength on time.

Some of these processes use traditional manufacturing methods to fabricate parts, while other methods have emerged more recently.

The success of any part/prototype also depends on the selected criteria of rapid manufacturing processes.

The following are five key factors that customers must consider before finalizing a rapid manufacturing process.

Purpose: What is your purpose behind rapid manufacturing? Parts and prototypes can be fabricated based on different purposes. There can be learning, communication, integration, milestones, low-volume production, high-volume production, and some others. After knowing that, it comes to your need. Do you want conceptual design, embodiment design, or detailed design?

Quality: Fidelity or the accuracy of the part required can decide what type of rapid manufacturing processes to look for. Quality is an essential factor to consider.

The quality of your parts also determines their life. Material selection also affects both the quality and the life of your parts. After knowing what quality you want and the material you prefer – your list of rapid-manufacturing processes will further decrease.

Quantity: It’s essential to know the required number of parts for the customers. It’s significant to decide the rapid manufacturing process as some parts/prototypes are only cost-effective for smaller quantities.

Furthermore, volumes play an essential role in rapid-manufacturing processes, and more significant parts sometimes require more time to fabricate.

Complexity: The complexity of the parts/prototypes also plays a vital role in the rapid manufacturing process selection.

These processes are great for fabricating too complicated small parts. But the customers should be cautious about the final design because complicated means very expensive too.

Budget/Cost: Cost and customer’s budget are important factors when selecting the most appropriate rapid manufacturing process.

Some processes like 3D printing are quicker but sometimes require some post-processing time.

Furthermore, casting can produce parts that are nearly identical to injection molding. However, pasts through casting can be used without any post-processing.

These post-processes can be very expensive with the tooling cost. The overall CNC cost mostly depends on the part’s complexity. CNC has a higher set-up cost, so its cost is directly linked to the overall production volume.

Once you understand these key factors, you can decide on a rapid manufacturing process by yourself.

- Define the purpose of your project for rapid manufacturing

- Establish a level of approximation (quantity and quality)

- Plan to identify quantities and outline the evaluation method

- Ensure that your costs are kept within your rapid manufacturing project budget

As rapid manufacturing processes continue to evolve, engineers are trying to determine which technique is best for a specific application.

What are the benefits of Rapid Manufacturing?

A part can be made relatively quick through rapid manufacturing, depending on its complexity. Using this technique can cost-effectively produce high-quality parts. The manufacturing ease it offers allows us to optimize our parts to maximum quality and precision in a cost-effective way.

Rapid manufacturing is the most viable option for customers who want to add personalization to their product designs. It offers a fully customized low-volume production.

It gave us an edge that few could deny. The following are some advantages that are by no means limited to one domain:

- Intensified speed and heightened accuracy

- Significant cost reductions:

- Proof of concept

- Rapid manufacturing is also famous because of the freedom of customization it offers to its customers

- Fast turnaround time

- The ability to manufacture complex parts

- Reduces material waste and cost

- When choosing rapid manufacturing, the engineers must identify any weak points and potential flaws in a physical model

- Complete freedom and flexibility

- In any case, with rapid manufacturing, functional prototypes are possible to be made quickly and effortlessly

- Understanding the parts better

- Lowering the overall risk

Since Sunrise Metal offers quick turnaround and affordable prices, our clients can quickly and cost-effectively verify their design flaws.

Our services can serve you well, and a decrease in time can also save overall costs, including material costs. In the case of rapid prototyping, China is a massive hub for it.

What is the connection between Rapid Tooling, Rapid Manufacturing, and Rapid Prototyping?

Rapid prototyping refers to the different additive manufacturing techniques used for the speed production of parts. This is where additive manufacturing started. Rapid tooling is another method that speeds up the part fabrication.

Furthermore, rapid manufacturing contains rapid tooling and rapid prototyping. Rapid prototyping services help overcome any barrier between the industrial design process and the casting and molding. It let us adopt different methods used to make enduring and precisely accurate parts. One regular use of SLA printing is making molds that later can facilitate mass production with exceptional details.

Adopting quick prototyping to make such a pattern is generally straightforward. However, current CAD software makes it conceivable to subtract one form from another and include injection molding channels. Rapid manufacturing speeds research and development as well as smooths out the production stages that follow.

By enabling engineers and others to investigate the dynamics of their thoughts outside the digital space, it lets thought pioneers make fast improvements to set up fabrication systems and polish the manners in which they work.

The vast majority of industrial processes often demand custom tools. These custom tools also need to be produced at scale.

However, accelerated rapid prototyping makes it easier to fabricate test versions of such parts. Furthermore, the results aren’t always as strong or durable as required to serve as dies, jigs, or other production aids.

Is Rapid Prototyping an essential part of the Product Development Process?

Prototyping is an essential aspect of the product development process. Rapid prototyping assists customers with transforming ideas into genuine parts. It helps extend these part designs to high-fidelity functional prototypes. However, these prototypes look and work exactly as the final parts.

Rapid prototyping also guides parts through multiple validation stages towards large-scale manufacturing. We can fabricate prototypes directly from the CAD data in quicker ways compared to any other technique.

And it also enables engineers to execute fast and frequent changes of their designs dependent on proper testing and feedback. Rapid prototyping raises initial plans to completely safe (low-risk) concept explorations that resemble final parts instantly.

Sunrise Metal is experienced in rapid prototyping, and it permits our engineers to go past virtual visualization. Doing so makes it even clearer to understand the design’s look and functionality.

Afterward, we can analyze the results side by side with the customers’ requirements. Part design always requires testing, refinement, and evaluation before getting to final production.

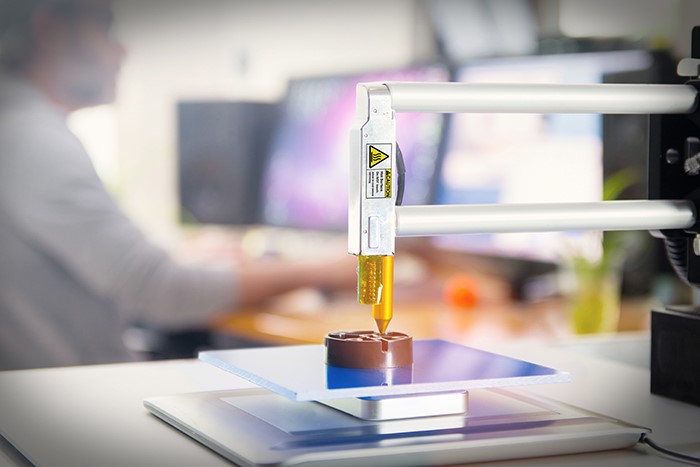

Rapid prototyping with 3D printing enables us to make more functional prototypes quicker by providing us the flexibility and resources. It also helps to execute changes right away, elevating this vital trial and error process.

At last, the rapid prototyping process assists engineers with improving parts to market quicker in cost-effective manners.

Is Rapid Prototyping the same as 3D printing?

Although, the simple answer to this question is “No.” In the current product development process, rapid prototyping is preferred alongside additive manufacturing. Furthermore, it’s preferred mainly because 3D printing enables us to fabricate prototypes rapidly in a cost-effective manner. 3D printing or additive manufacturing is a manufacturing process, while prototyping is the production of final parts.

Besides, 3D printing could be used to make rapid prototyping all alone or combined with different processes.

They are not similar but more related to each other. Making rapid prototypes is not the only way of using 3D printing. However, rapid prototyping also involves other methods alongside 3D printing. Furthermore, rapid prototyping through 3D printing is the fastest way to get tangible results.

The purpose of prototyping also matters because all the 3D printing methods come with different levels of quality. However, additive manufacturing technologies have moved along and have made significant progress towards producing high value and quality parts.

Which is the best Rapid Manufacturing Process?

Selecting the best rapid manufacturing process is critical to the success of your prototypes and final parts.

Every rapid prototyping process has its advantages. These advantages can be speed, material, cost, quality compatibility, features, fidelity level, and improvement and development stages. Rapid-prototyping doesn’t need to be restricted to one process; one can use more than one process to manufacture parts. There’s no best process except for processes that will better line up with your project’s requirements, quality, and cost.

At Sunrise Metal, we don’t push one manufacturing process over another. Instead, we review and analyze your project and offer you direction on various rapid prototyping and low-volume manufacturing processes.

The following are experiences into how different rapid prototyping and manufacturing processes are used.

Rapid prototyping refers to the rapid fabrication of parts with Computer-Aided Design during the product development cycle’s earlier design phase. Afterward, it can be used throughout the design process. Sunrise Metal offers effective rapid manufacturing services, which helps engineers avoid potential risks.

What are the five objectives of Rapid Manufacturing?

In this quick progressing market, customers need to fabricate and introduce new products quicker to remain competitive.

Since quicker product development became vital to customer success, rapid-manufacturing turns into the most significant component of new product development.

The following are five core objectives that can be accomplished through rapid manufacturing.

Faster new part development: It plays a vital role in the process of fabricating parts because it speeds up the new product development process

Initial stage validation: We can perform early-stage design validation of the form, function, and fit of the part design through rapid manufacturing. In this way, we can achieve accuracy, precision, and quality even before the actual part production.

Final stage verification: Rapid manufacturing helps the engineers perform final stage verification of the parts against the technical requirements and business objectives.

Allows functionality testing: Rapid manufacturing allows us to test and analyze the design/part concept’s objectives and finalize the part specification. We can avoid overall risks and part design errors through functionality testing.

Provide hands-on user experience: The final parts through rapid manufacturing give the customers a complete hands-on user experience to get feedback earlier.

How precisely does Rapid Manufacturing can reach?

In the realm of rapid manufacturing, precision means how closely a machine can fabricate parts against a specified dimensional range.

Rapid manufacturing can produce accurate and better surface finishes compared to other techniques. Finalized parts accuracy can be the same between rapid prototyping and mass production.

The parts with more challenging functional requirements and complex structures, their precision and accuracy tolerances are specified in the same manner as traditional manufacturing methods.

What are the different applications of Rapid Production Parts?

In the context of rapid part development, rapid production can be an invaluable tool. Its process consists of stages where parts are fabricated to quick market availability and tested to verify and improve designs.

Rapid-manufacturing typically an iterative process to ensure that any flaws are detected before final parts are ready to be manufactured. The rapid production technology is very versatile in the shapes and parts it can manufacture. It has different applications that are more reliable than standard manufacturing techniques.

Rapid production is mostly useful in the following applications:

- Medical equipment models and parts

- Artwork and models for engineering analysis

- Parts for pilot series production in the automotive and aerospace industry

- Patterns for die casting

- Rapid production where tooling costs for die casting or injection molding would be high

- Building functional prototypes

- Parts of high geometrical complexity which cannot be fabricated through molding, grinding, milling, and die casting

What are the benefits of Rapid Production Tooling?

Rapid production tooling is a quick, cost-effective, and flexible part fabrication technique designed for low-volume production.

Rapid tooling can manufacture high-precision and quality parts. Furthermore, rapid production tooling involves different processing technologies. It mostly depends on the part design parameters that the rapid tooling process is most appropriate.

Processes like CNC machining, 3D printing, and many others are part of rapid tooling and offer different and multiple advantages. A few of the most common and beneficial advantages rapid tooling offers are the following:

- Help to decrease product development costs

- Offer superior design testing

- Offers fully part customization

- Variety of material options

- Top-quality part fabrication

- Handles customized molds for personal applications perfectly

- Shorter tooling time as compared to conventional tooling

- Faster time to market

- Get rid of troubleshooting existing problems

- Obvious time advantages on shorter product lifecycle

- Enables us to manufacture a wide range of injection moldings

- Made perfect custom molded products

- Offer highest surface quality

- Mechanical properties of original materials are maintained

- Over-molding is possible

- Facilitates us to manufacture multi-component parts

What is Metal Prototyping?

Prototyping through solid objects to produce machine parts, models, and prototypes are called metal prototyping.The solid parts are fabricated a single layer at a time and offer top-quality parts rapidly as an output.

Several options are available in today’s market and emerging for the fabrication of metal prototypes. However, some of them are the following:

- Machining prototypes from metal alloys, mostly aluminum

- 3D printing using different new technologies

- Prototype Die Casting and Aluminum Prototype Manufacturing

For metal prototype manufacturing and production, the engineers must consider all the advantages different individual processes offer. Furthermore, metal prototyping weighs how metal properties, overall cost, and its similarities to production intent bear upon the process selected.

Metal prototyping is chosen to make metal parts in automotive, aerospace, technical design, medical, aviation, construction, and other industries. Following are the rapid prototyping capabilities:

Heat Resistance: For metal prototyping, metal prototypes are heat resistant because of their higher melting point. For that reason, metal prototypes have less risk of degradation when exposed to high temperatures.

Incredible Strength: Metal prototypes, especially aluminum prototypes, are very strong, exceptionally durable, and extremely hard. Even when fabricating precisely detailed metal prototypes, it’s sure that these prototypes can withstand anything and hold the design perfectly.

Versatility: Using metal in prototypes provides versatility. Metal prototyping allows the design freedom in a range of applications. Furthermore, metal prototypes made out of aluminum are high in performance and excellent in quality.

Cost-Effective: Metal is the most cost-effective option over any other. Metal prototyping is a unique way to reduce overall costs in specific applications.

Why make Metal Prototypes instead of Plastic Prototypes?

Metal prototypes contain a higher scale potential value for the industry. However, plastic prototypes are for simple parts and established for low-volume manufacturing.

You ought to know that they are different from each other in two different senses. First, in the sense of part material and second in the sense of hardware’s physical performance. Hence, metal and plastic prototypes are not interchangeable in any means and as manufacturing solutions.

Furthermore, this is valuable information that must be applied early in the design stage for the best possible results. Temperature and heat are two of the most critical issues for plastic prototypes than for metal prototypes.

As a result, the above factors make metal prototypes a better choice as compared to plastic prototypes.

What surface treatments do Rapid Manufacturing Companies use?

Sometimes, rapid manufacturing processes contain some unique challenges that can be overcome easily. These challenges include low surface quality and surface treatment of parts that are worth overcoming. To improve the final part surface quality, several surface treatments have been introduced.

These surface treatments are most appropriate for the complex parts in design with a handful of features and curves. Furthermore, they contain a limited percentage of plane surfaces.

Recently, porosity and grain structure have mainly been overcome through rapid manufacturing. The surface roughness makes inspection difficult and reduces the performance of parts by providing crack initiation sites.

Surface treatments are required by rapid prototype companies to improve the surface finishes of the finalized prototypes.

Following are some of the critical surface treatments that rapid manufacturing companies use:

Anodizing: Applied to change surface properties of prototypes and parts through electrochemical techniques. The following are reasons to choose anodizing as a surface treatment for rapid manufactured parts:

- It improves corrosion resistance, Surface hardness, aesthetic appearance, and wear resistance

- It reduces electrical conductivity

- It reduces surface reflection and helps parts to dissipate heat

Painting: It is mostly used for prototypes and low-volume manufactured parts. Customers can produce any desired surface finish through painting.

Laser Etching: We apply pad printing for custom colors and CNC customized aluminum stencils appropriate for any level or semi-curved surfaces. Silk-screening is likewise accessible, which might be more appropriate for some different applications.

Sanding and Polishing: Wet sanding and dry sanding are the two possible ways of using sand as a surface treatment. Both treatments are used to prepare a part surface for painting and contain some unique surface textures.

Furthermore, parts and prototypes manufactured using aluminum alloys can achieve highly finished surfaces to mirror polish through sanding and polishing.

Electroplating: It involves a chamber in which the part is placed. This chamber is where different abrasive media impact the surface under pressure. Electroplating decreases friction and increases the thickness of the parts.

The best rapid prototype companies utilize these surface treatments, and Sunrise Metal is one of them. We overcome all the challenges related to these surface treatments.

How to Get Quality Fast Fabrication Service?

To ensure that you get the quality, fast-production services, the following are some features that companies must provide to customers:

- Demonstrate the appearance, dimensions, and features of your product

- Save money and time by identifying and reducing design flaws

- Test the market with your product before final production

- Improve and streamline the production process

- Fabricate multiple versions with different surface treatments and finishing processes

Our speed-fabrication services ensure that your designs and ideas are actualized in the real world in the minimum possible time.

Our services also reduce risks by thoroughly testing the parts with low-volume production in the early stages of product design.

At Sunrise Metal, our team is specialized in the fabrication of high-quality, cost-effective prototypes and parts.

Sunrise Metal is the perfect one-stop quality rapid fabrication services provider with a vast library of technologies and services. We are capable of fulfilling your rapid prototyping needs.

How to make Rapid Manufacturing faster?

Rapid manufacturing usually implies a tradeoff between fabricating speed and quality. Rapid manufacturing software and hardware determine how fast it can be. Its speed also can be improved by improving the software and machine hardware of the rapid manufacturing processes.

Software:

The part’s fabrication ultimately influences the rapid manufacturing process in shorter print times. Following are some factors through which rapid manufacturing speed can be determined:

- The part’s height in the build direction: By minimizing the parts’ height, the fabrication layers also decrease. As a result, part fabrication time decreases, which became a reason behind fast manufacturing.

- Material’s volume and contact area with support structure: Material waste depends on the total material used in rapid manufacturing. Less material used means less material waster, which saves machining time. This became the reason behind fast part fabrication time and finishing time.

- The total surface area quality: The parts surface quality can be increased through different surface treatments. Rapid manufacturing processes mostly increase the surface quality without requiring any external machining or processes.

Hardware:

Increasing the rapid manufacturing speed through machine hardware improvements can take the following forms. Furthermore, rapid manufacturing speed also depends on the following factors:

- Using different types of printheads for different rapid manufacturing processes like 3D printing

- In some cases, including additional laser to melt the filament before going to the extruder

- Processes like 3D printing; adding more printheads can increase the fabrication speed

- Using particular types of materials for specific rapid manufacturing technologies