Specialized, Full-service Tool and Die Company In China

Sunrise Metal has established itself as an expert tool and die company in the global die cast industry. With an experience of over 10 years, Sunrise is focused on providing turnkey solutions to meet the demands of your project.

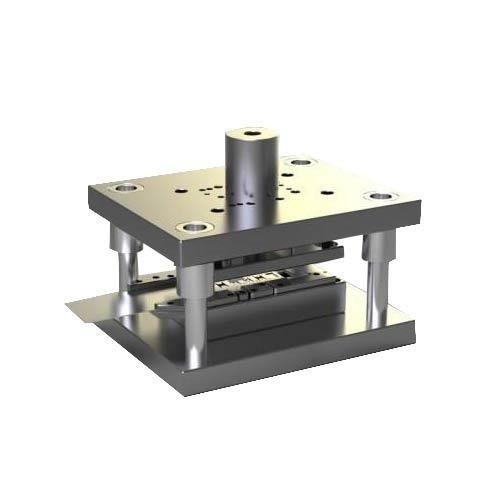

We have dedicated, in-house resources to facilitate your requirements at a professional level. Our capabilities allow us to design and build small unit dies to large progressive dies. You can attain our wide range of services that can provide you with a complete package from the blueprint to end result.

In-depth tool and die manufacturing services with complete control over the quality.

Competent Service Provider of Tooling And Die Manufacturing in China Through Up-to-date Equipment

Die Casting Tooling Capability To Fulfill Your Projects

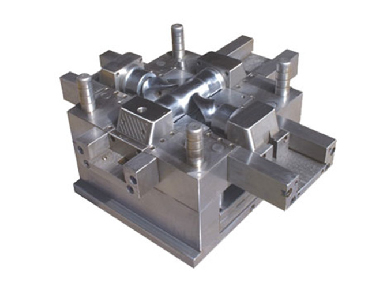

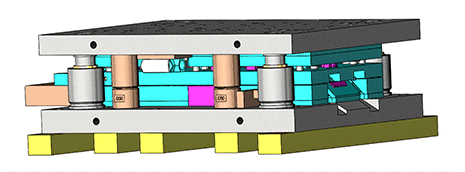

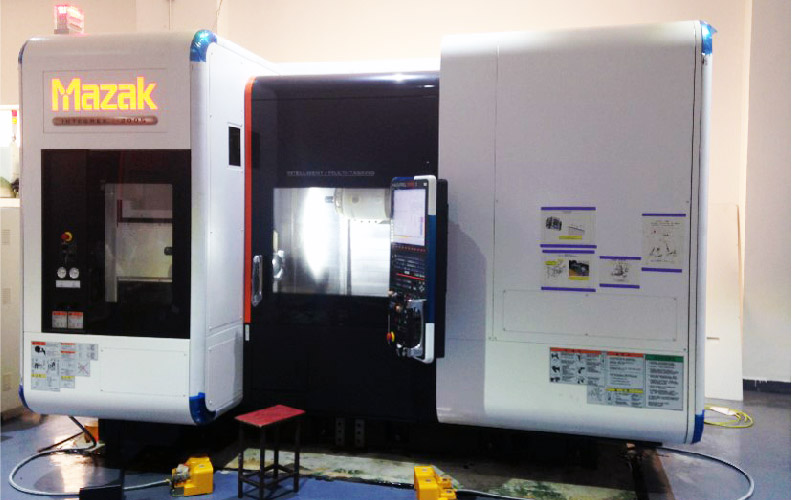

Sunrise Metals provides a superior tool and die production solutions. Our advanced engineering and equipment potential allows us to bring quality to your project. With our computer design and programming, tool room, and manual machining, we can be your go-to solution for any project. Our equipment for tool and die making includes:

- Complete workstations

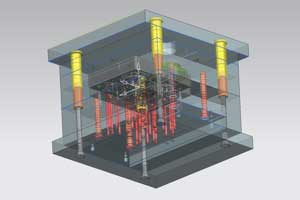

- Die Simulation Softwares

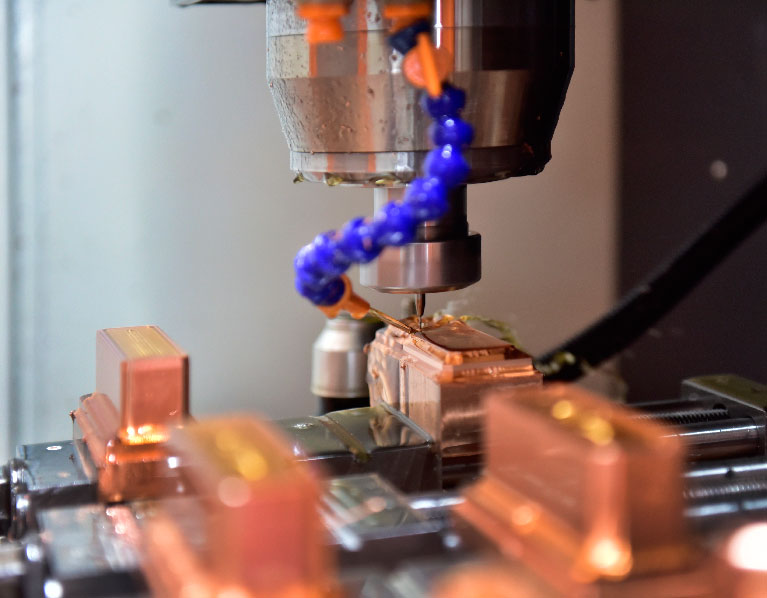

- CNC machining centers

- Rotary Surface Grinders

- Radial Drills

- Tryout presses

- Electric Discharge Machines

- Vertical Band Saws

- Tool Room Lathes

- 2 – Cutter Grinding Machines

- Tool Setters

You can keep track of the complete step-by-step production that your project receives. Our team coordinates with you at every step to keep you informed of the progress.

Sunrise Metals handles each requirement in-house and produces complex parts with intricate designs upon request. Your unique needs are met by our highly experienced and skilled professionals. No requirement is impractical in our tool and die workshop.

In addition to in-stock, ready to ship die specimens, we provide customized services that are delivered as early as possible. Our team can work with high strength, dual-phase materials using our advanced technologies to give you precisely what you need.

Our engineering services give us complete grasp over requirements and produce every part that meets your demands. These include:

- Forming simulation

- Reverse engineering

- Process layouts, etc.

Productive Die Casting Toolings And Dies Supported By High-Tech Process Machines At Sunrise

Leading Tool and Die Company that Provides Quality Workmanship

A team of dedicated professionals meeting the needs of every client.

The ultimate goal for Sunrise Metals is to achieve customer satisfaction through detailed and personalized services. Our team of professionals is trained to provide quality at every step of production.

Our experts have worked on their skills and have upgraded the equipment necessary to fabricate every tooling form. Your needs are met with the flexibility in our process of production. We use computerized systems to store every requirement and keep a record of it for future uses. This helps our team to make the process foolproof for our clients.

- High Class Die Casting Tooling Equipment List

- Premium Quality Measuring Equipment List

| Tooling Shop (Nantong) | Brand | Type | Stroke | Unit |

| Grinder | TATUNG-OKUMA | KGS-615AHD | From 380mm to 1600mm | 4 |

| Drilling | Shenyang Machine | Z3050*16/1 | 1600mm | 1 |

| Sawer | Juli | MJ034W | NA | 1 |

| Lather | Shanghai 2nd Machine | C6250A | 1000mm | 1 |

| EDM | EDM Korea YIHAWJET Taiwan | NA | From 438mm to 1100mm | 8 |

| CNC | Local Brand | SONYU-SL850 | From 850mm to 3015mm | 5 |

| Wire Cutting | Local Brand | DK7763 | 800*630mm/1000*800mm | 2 |

| Milling Machine | Local Brand | QJM-S2 | NA | 4 |

| High-speed Cutting Machine | Local Brand | 906148 | 750mm | 1 |

| Deep Hole Drilling | Local Brand | DHD-1513 | 1513mm | 1 |

| Die Spotting Machine | Nice Dongguan | NC150-1511 | 1400mm | 1 |

| EDM/wire cutting Combined Machine | Local Brand | DK7755 | 550*630mm | 1 |

| EDM for a very small hole | Local Brand | DD703 | 300*400mm | 1 |

| 3D Laser Scanner | Si kan Hangzhou | HSCAN771 | NA | 1 |

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

Tool and Die Manufacturer with Quality Verification

Carrying studies and tests that ensure the quality of product to meet customer’s standards

Sunrise Metal is an IATF 16949 and ISO 9001 certified tool and die supplier in China. To meet these standards and customer’s standards, many tests are carried out on your products. Our quality control equipment ensures that the conditions and criteria are being met. Your product has to pass specific tests like scanning, inspection through CMM inspection machines, etc. before delivery.

Sunrise Metals will provide you complete service from quoting a price to delivering the product. Feel free to ask us a question. Contact us today.

TOOL AND DIE COMPANY: THE ULTIMATE FAQ GUIDE

Tool and die manufacturing is part of the industrial production of multiple parts and components with the help of tooling and dies. The process involves simulation through software, as well as traditional manufacturing die castings, metal extrusions, and prototypes. Tool and die companies are efficient and employ cost-effective ways of producing parts for automobile, telecommunication, domestic, marine, and other sectors.

- What is a tool and die manufacturing?

- How do tool and die companies create tools for die casting?

- What is the difference between a tool and a die?

- What does a tool and die service offer?

- How cost-effective is the tooling and die making process?

- How is tooling carried out by tool and die companies?

- What are some of the components that are manufactured by tool and die supplying companies in China?

- What types of equipment and production facilities are used by Sunrise to manufacture precision tools and dies?

- What press tools are created by tool and die manufacturers?

- How is a vacuum die utilized by tool and die companies?

- What are the applications of tool and die services in different industries?

- What tooling advantages are provided by Sunrise Metals in China?

- What is die cast die making? What steps are carried out by tool and die suppliers in China for the process?

- How is die making carried out?

- Which raw materials are used by tool and die maker for die casting die making?

- How many types of die are manufactured by tool and die suppliers in China?

- What factors should be considered by tool and die companies when manufacturing dies?

- What tool design services are offered by tool and die companies in China?

- What quality measures and engineering operations are implemented by Sunrise as a leading tool and die supplier in China?

- What technologies are used by tool and die manufacturers to create the best tooling?

- What is the difference between die cast dies and plastic molds? Is Sunrise Metal certified as a tool and die manufacturer?

- What kinds of tool and die service does Sunrise Metal offer?

- Can you do the trial run with die and mold made by Sunrise Metal?

- As a tool and die maker, what’s Sunrise Metal’s typical lead time?

- What software does Sunrise Metal use for tool and die design?

What is a tool and die manufacturing?

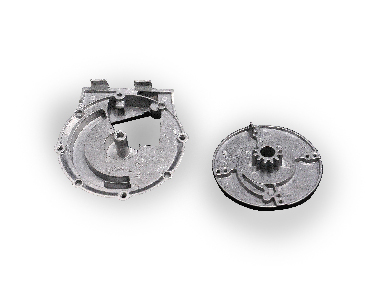

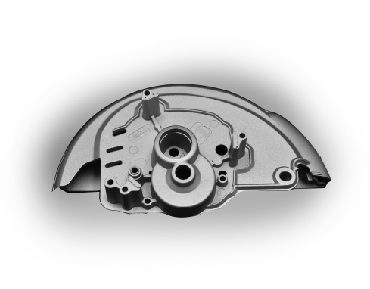

Tool and die companies use the industrial process to create dies, molds, jigs, and fixtures that are later used in the manufacturing of other parts. The tool and die shops mostly manufacture and fabricate the dies which are the most important part of the casting processes.

Tooling

Tooling is the process of engineering and designing the tools that are required in the making of industrial components. The tool and die manufacturers are coming up with many advanced techniques that help in the tooling of multiple parts using one piece. For every different type of part, a unique tool is used. This helps in producing a unique part of the machine many times.

Different types of tooling are employed for the production that includes fixtures, jigs, gauges, molds, dies, cutting equipment, and patterns. These toolings affect the output of any machinery directly.

Die Making

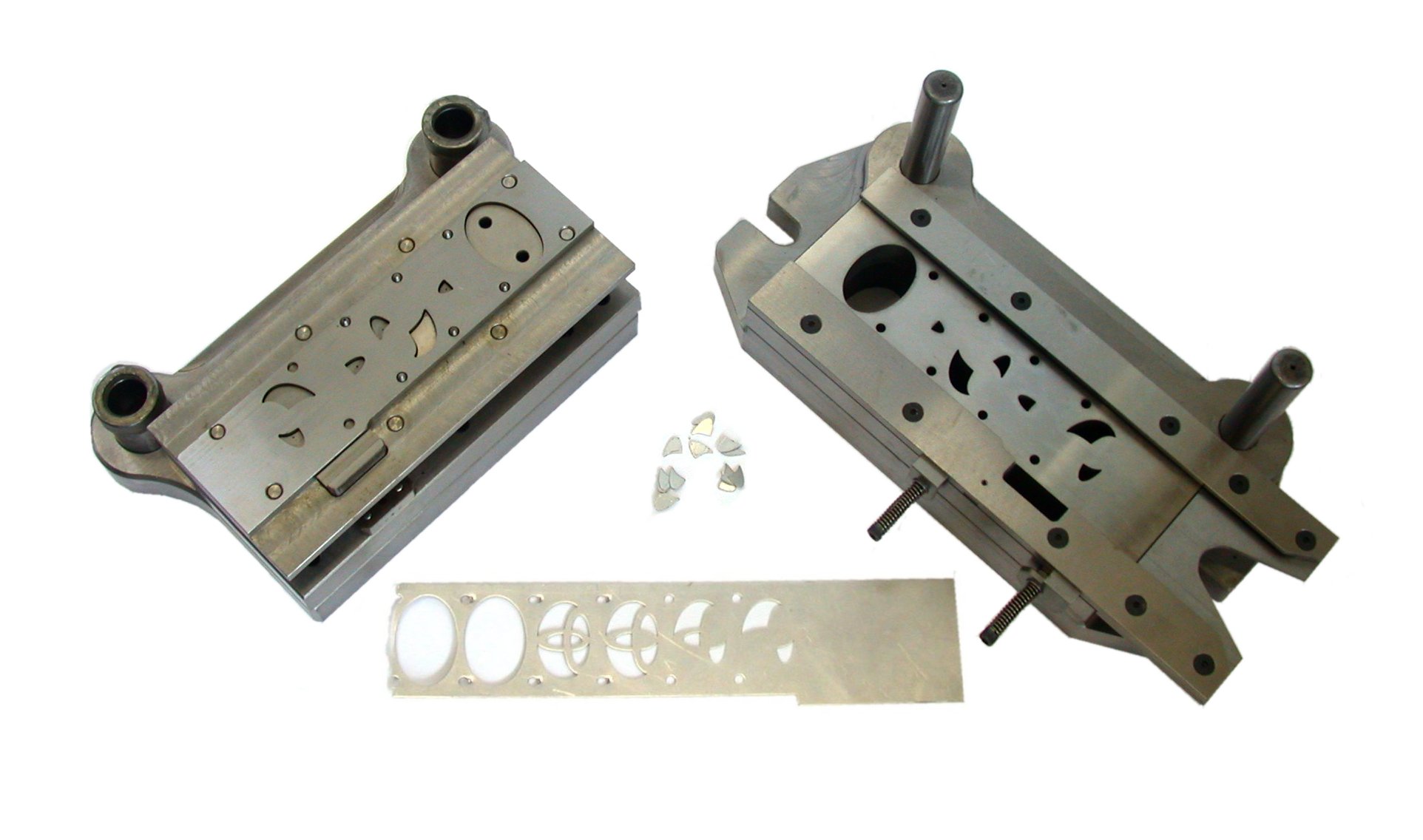

The process of die making is used by tool and die manufacturers. Die is one of the tools manufactured by them that is used for cutting and shaping metal parts. They are customized to the part that they are going to manufacture. The die casting is used in the production of dies. There are many components to the die that are utilized for different purposes.

How do tool and die companies create tools for die casting?

Manufacturing companies make tools and molds to manufacture different products for their customers. The attributes of those tools, shape, uniformity, quality, etc., directly affect the die casting products.

Simulation

Manufacturers use modern IT technologies to draw the geometry and dimensions of tools. The simulation process takes care of elements like thinning, wrinkling, fracturing, stretch, compression, spring back, and trim line optimization of the tool that is being manufactured.

3D CAD/CAM Modeling

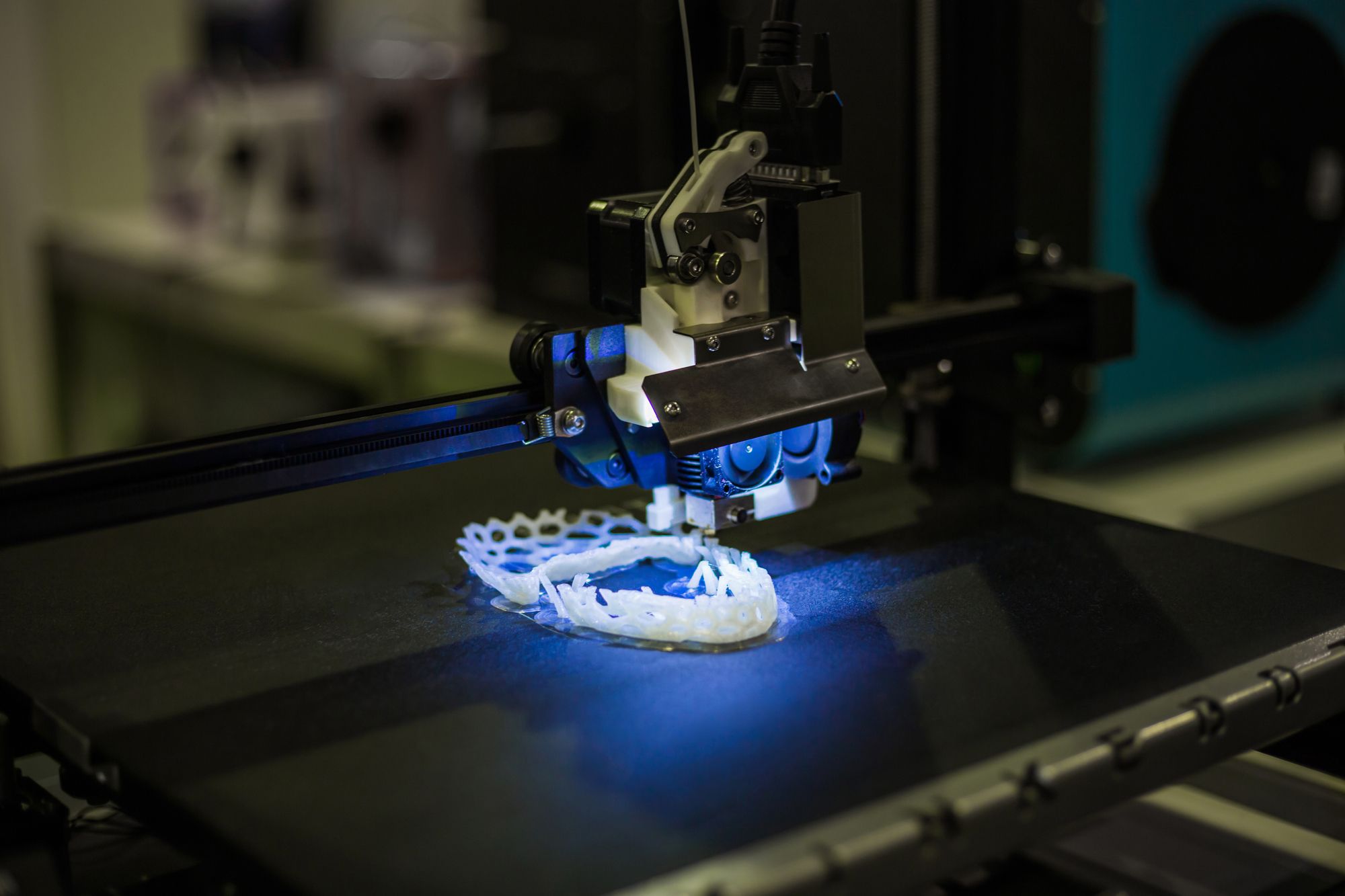

Any issues during the tool simulation process are addressed in the 3D modeling with CAD or CAM software. It is helpful in testing and validating the final design of the tool before taking it to the next step of manufacturing.

The CAM/CAD modeling help tool and die manufacturers to create a complete concept using 3D technologies. Each aspect of the design is covered using this software. The design is easily converted into the machine language for any automated and CNC machines.

Manufacturing

Once the perfect design of a tool is ready, the tool is observed for material selection. Next, the material is passed through a production process to create a precise tool that meets all of the customers’ needs and standards. A sequence of operations delivers the final product of the desired tool.

What is the difference between a tool and a die?

The terms “tool” and “die” are used interchangeably so often that most people drive the same meaning from them. But there is some functional difference between the two.

The simplest way to put this is that all dies are tools, but not all tools are dies, which means that dies are a subset of tools.

Any mechanical device that is used to mold, support, cut, or form metals are called a tool. Whereas, the tools that affect the shape of the metal are known as dies.

So, by these definitions, a fixture is a mere tool, but a punch block is both a tool and a die.

The equipment used by die makers is specialized and has to be precise. They are the tools that are used to change the shape of the metal. Tools, however, are a vast category. They contain dies and other types of tools as a subcategory. The tool and die manufacturers differentiate between the two categories and know that die making needs to meet special production standards.

What does a tool and die service offer?

Many die casting companies offer tool and die services in which they make tools and dies used to manufacture metal products. Most of the tool and die manufacturers in China are a complete solution to die-cast needs of many businesses.

Sunrise Metal is a one-stop-solution and is focused on providing the following services:

Aluminum Die Casting

Die-Cast production as well as die-cast tooling is offered by many tools and die manufacturers. Aluminum being the ideal metal for these processes is mostly used in such processes. The premium service providers in China include this service as this makes them a one-stop-shop for all manufacturing needs.

Sunrise caters to high precision, low-volume orders, and has advanced R&D capabilities to support complex designs and cost-effective mechanical parts. The best equipment goes into the production of die-cast products that are accurate, stable, strong, and light-weight.

Zinc Die Casting

The zinc die casted products need supreme tooling to produce modified zinc metal parts. The tool and die companies mostly focus on every aspect of die cast manufacturing. The addition of these services makes them one of the leading companies.

Zinc die cast composition is sometimes used in places where the combined properties of zinc and aluminum can produce the best desirable results.

Rapid Tooling

Rapid tooling is mostly offered by every tool and die company. The die casting dies or molds are the main requirement for every process. Rapid tooling ensures rapid results and so it is a major service that makes tool and die manufacturers stand out.

Common tools in tool and die services are fixtures, cutters, metal forming rolls, etc. Depending on the type of work that the customer needs the tool for, a tool and die service can also modify any standard tools to best suit the required function.

Similarly, custom tool fabrication is another option for customers if no standard tool meets their needs. Common dies that are manufactured, supplied, and maintained in a tool and die services are punches, steel rule dies, die sets, etc.

How cost-effective is the tooling and die making process?

The process cost depends on different factors. The tool and die companies in China give an estimate of the services by considering each aspect.

Tooling Type

The type of tooling your product requires directly affects the total bill you are going to get. The tooling type required also depends upon the number of parts you are trying to get from the tooling. For example, progressive dies cost more than the single cavity or hand-fed line dies. This is due to their capability to yield a higher production rate.

Part Complexity and Geometry

The complexity of the part is also a factor that will decide what you are going to be charged. If the part is simple and the tooling required for the production is minimal then the whole process will be lighter on the pocket. However, parts requiring extensive prototyping, tooling, and simulation services always cost more. The detailing needed in such parts is what makes them more expensive.

Part Material

The material used in part production is one of the main factors that affect the cost of the process. If the material is easily machinable and has a lower melting temperature, then the tooling of the part is easier and hence the lower cost is involved. However, when the hard-to-machine materials are used, more tooling is required in the process. Hence the cost increases with every additional step too.

Capabilities of the manufacturer

Sometimes, the tool and die manufacturers do not offer every service required in tooling and die making. They have to outsource the services. In this case, the cost is more than what it would have been if it was a complete one-stop-shop for tool and die making. The cost also might vary due to the technologies used. If the tool and die manufacturer doesn’t have efficient equipment and advanced technologies, it might also result in additional costs.

Sunrise Metal takes into account all of these factors and offers the most cost-effective solutions, without every compromising quality.

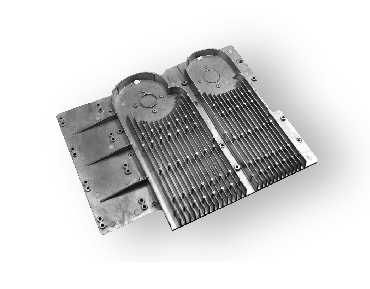

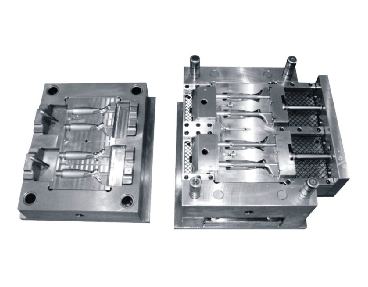

How is tooling carried out by tool and die companies?

Tooling is the process of acquiring components and parts for the manufacturing of a product. Proper tooling has a direct effect on the final product’s quality, capacity, efficiency, lifecycle, and even pricing.

This tooling is carried out mostly in the form of die casting molds which are produced as the most important part of a die casting machine. The mold consists of hardened tools and steel dies which form a cavity to make the design possible.

After a careful review with customers for the feasibility of tooling design, mold features are modified on the front end to enhance the quality. Removable inserts can be provided in molds beforehand so that maintenance is kept at a minimum.

To create high-quality metal or plastic parts, tool and die manufacturers create high-quality molds. Tooling of metal or plastic is carried out as follows:

- The design is studied and improved by the designers.

- Mold is created according to the design.

- The quality of the mold is enhanced with the cooperation of the client.

- Removable inserts and cavities are used in the mold according to the design.

- The process of casting is carried out using the casting tools.

What are some of the components that are manufactured by tool and die supplying companies in China?

Tooling and die making are not the manufacturing processes but help in the manufacturing of the metal parts. Tool and die suppliers in China use these processes to perfect their manufactured parts.

This is how tooling is used by manufacturers:

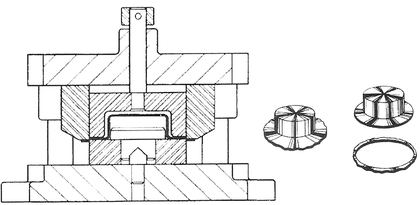

Die casting

The process of die casting is a popular method to make metal parts. As seen by the name, it depends upon the dies for accurate construction. The tooling used in the process is the main factor that defines the accuracy and precision of the produced part. The die or mold is filled with molten metal and the produced part is ejected from it. Other tooling processes like cutting, sawing, etc. are used to complete the manufacturing.

Prototypes

The prototypes are often produced using the tooling techniques completely. This process mostly involves rapid tooling techniques that are used to work upon the metal piece provided. The dies are built rapidly and the prototypes produced are precise and accurate. If the prototype is produced from any other process, it is tooled to attain perfection.

Metal Extrusion

Dies are used in the process of extrusion and define the structure of the part being produced. The desired shape depends on the type of die used. The product, later on, experiences the tooling which helps in the completion of the product.

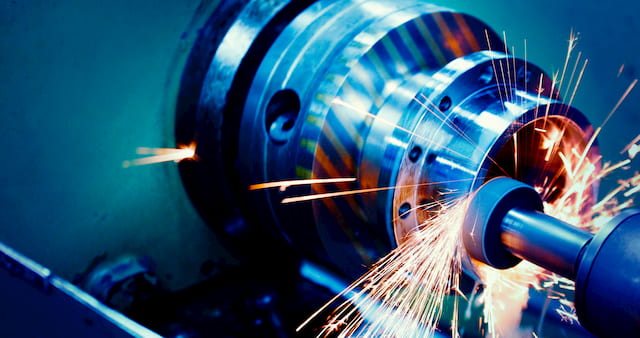

What types of equipment and production facilities are used by Sunrise to manufacture precision tools and dies?

Sunrise is one of the leading tools and die manufacturers in China. Different advanced techniques and equipment are used in the manufacturing of tools and die at Sunrise. The following type of equipment is mostly used by the experts here:

Machining Centers with capabilities of up to 7 axes

Sunrise Metals uses 7 axes, 5 axes, and axes CNC machining centers. These machining centers produce tooling and die with precision. The automatic tool changing capability of these machining centers reduces the human error and provides accuracy. The tooling produced helps in many manufacturing techniques.

Die Making CNC and EDM machines

Other than the traditional process of die casting, Sunrise also uses automatic processes for the manufacturing of tools and dies. The processes include accurate Electric discharge and wire electric discharge machining. Our advanced EDM machinery helps in the production of the desired shape by using electrical discharges.

Surface grinders and cutting machines

The dies and tools that have the unique requirements are also catered at Sunrise. As the premium tool and die manufacturers in the state, we achieve precision using our surface grinders and cutting machines. Once the tooling for processes like aluminum die casting is produced, the grinders and cutting machines help perfect that tooling. The machines are helpful in obtaining the required parts.

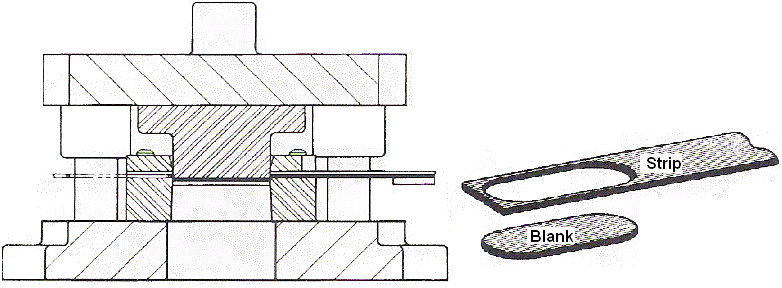

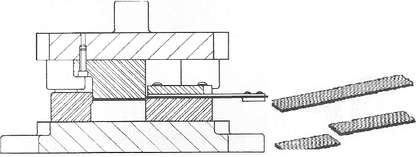

What press tools are created by tool and die manufacturers?

Tool and die manufacturers use press tools to cut, shape, or mold the metal parts. They are an important part of manufacturing. The tool and die manufacturers build many types of press tools to carry out different actions.

Blanking tool

These press tools are used to obtain the tools that are easily cut out of the metal sheets. The tool is pressed upon the sheet and cuts out the required part in no time. The part of the sheet unused by the press can be reused by other press tools or blanking tool for further manufacturing.

Piercing tool

This tool is used to cut out holes in the dies or metal sheets. The tool of the hole size is pressed over the required part and the material is taken out of there. The obtained part will have the holes just as required by the design.

Cut off tool

This press tool is used for the sheets that were used to create the blanks for dies. The part that is still unused in the sheet is cut off by pressing this tool at the right point. The sheet will be cut into two parts and the unused part will be again used for further blank options.

Parting off tool

The parting off tool is a press tool used as the cut off tool. But instead of cutting the sheet into two by pressing it in one direction, it is used from two sides. The parallel cutting results in more waste of the material.

Trimming tool

Sometimes the die created is not precise. It requires some tooling to obtain an accurate part. The trimming tool is pressed upon the part to trim away all the unnecessary material from the die or tool.

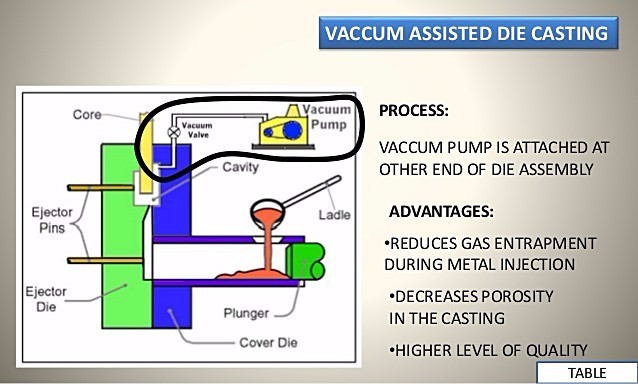

How is a vacuum die utilized by tool and die companies?

Vacuum die is manufactured by tool and die supplying companies due to the many benefits they provide. This die uses the vacuum to pull all the waste material from the process of tool making.

The vacuum dies have a different assembly than usual dies. The mold cavity and the shot sleeve are attached to a vacuum-assisted system. This system sucks out all the air and makes the process of die casting porosity-free.

Molten metal is injected into a steel mold under high pressure called a die. In the mold cavity and the shot sleeve, a vacuum is drawn in before the injection shot happens. This is possible through the mold’s gating system and casting cavity.

What are the applications of tool and die services in different industries?

The tools and dies are used in various industries today by the manufacturers. This is to make the process of manufacturing more accurate and precise. New tools are introduced every day and the improvements in the dies are made using these services.

Medical

The industry requires precise instruments for sensitive procedures like that of surgery. While manufacturing tools and dies for this industry, each specification is carefully considered. The tooling for these instruments is tooled as well to obtain perfection.

Marine

The tooling used in this process assures that each part sits well with the machinery used underwater. Composite tooling and fabrication are used to machine these parts. A certain tolerance is required for each marine part that is then tooled by expert machinists.

Automotive

The tools and dies have vast applications in the automotive industry. Traditionally, one die was used for the production of many parts in the industry but this changed with time. Today, each unique part of the automotive uses a unique tooling option.

This helps in the customization of the automotive as a whole. The die used in the production of unique parts can be used for thousands of those parts for other copies.

Aircraft

With innovations in the industry on a daily basis, aerospace parts need to be customized. Every part is constructed to provide efficiency to the machinery as a whole. Dies and tools are used to provide that efficiency. Customizable dies or progressive dies are used in the process of making these parts.

What tooling advantages are provided by Sunrise Metals in China?

The tooling process at Sunrise is superior to the other service providers in the industry. This is due to the certain benefits that we provide. Some of these advantages are:

Precision

Tools and dies supplied by Sunrise provide precision in the manufacturing process. The manufactured part experiences tooling to give it net shape. The production of the part goes through strict process controls that maintain high quality.

Tolerance

The tooling provided at Sunrise provides tolerances to the metal parts to make them function properly even under extremely tight specifications. The machining is done with automatic tools and has very low chances of human error.

Fast Turnaround at low cost

The tooling provided by Sunrise results in a fast turnaround of the production. The metal parts are completed at a very low cost in a very little time. Professionals at Sunrise make sure that you market your product faster and give you a competitive edge. Our tooling services are advanced and effective making them affordable for every industry.

Primer Surface Finishing

Our tooling services help eliminate the defects of your required part. With complete tooling, we increase the corrosion resistance and improve the conductivity of the metal part. These services also help enhance the aesthetics of the metal part.

What is die cast die making? What steps are carried out by tool and die suppliers in China for the process?

Die casting is a process in which molten metal is forced into a mold at a high pressure to obtain the specific shape. The process of die casting, as seen from the name, makes use of dies. Here’s how:

Where are dies used:

The reusable molds in the die casting process are called dies. They are the central part of the whole process. Molten metal is forced into the dies and the formed metal part is ejected through this die. The properties of the die are the main factor on which manufactured part accuracy depends.

How is die making carried out?

The process of die making depends upon the type of parts it is going to manufacture. However, the generic process to carry this activity out is as follows:

- The design of the die is created.

- The design is converted into a digital file.

- Simulations are carried out to ensure the functionalities of the tool.

- The design is converted into a computer understandable code.

- The code is fed to the machinery.

- Under the supervision of a machinist, the production is carried out.

- The tooling of the die is completed with surface finishing to remove any faults.

Which raw materials are used by tool and die maker for die casting die making?

The choice of material for die making depends upon the process it is going to carry out. It also depends upon the material to be used and the complexity of the production process using the die. A large range of materials is available to be used in the process and the right one is carefully selected to produce the best results.

Some of the most common materials used in the process of die casting die making are:

Steel

Steel is the most popular metal to be used as die cast die making material. This is due to the different choices it provides in terms of composition. The steel used in die making is formed by adding small percentages of different materials in it.

This is done to make the steel handle the pressure and the temperature change of every metal that is poured into it. Depending upon the composition of added alloys, the different types of steel used are carbon die-block steel, High –Alloy Oil-Hardening Steel, Manganese Air Hardening Steel, Chromium Air Hardening Steel, High Alloy Air-Hardening Steels, and more.

Non-ferrous alloys

The non-ferrous alloys are also used in the production of dies. They are low cost but provide efficient production. Materials like Kirksite and Cerrobend are the most common non-ferrous alloys being used in die making.

Non-metal alloys

Not only non-ferrous alloys are light on the pocket but non-metal alloys are too. They are used to make dies where a small quantity of production is to be carried out and where the durability of the material is not a priority. Steel is sometimes too expensive for such productions.

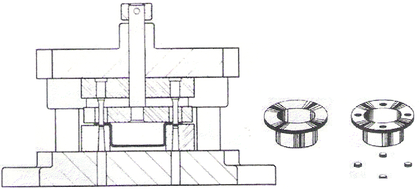

How many types of die are manufactured by tool and die suppliers in China?

The types of dies manufactured by tool and die maker of China are classified on the base of their strokes and what happens with each stroke. The list is quite comprehensive when it comes to stroke action.

Simple Dies

Simple dies are the ones that perform only one action per stroke. They can carry out different types of actions like bending, forming, drawing, etc. With each stroke, one of the listed actions is performed.

Compound Dies

Compound dies are the ones that are capable of performing multiple cutting and forming actions with each stroke. They only perform the cutting operations therefore they are also known as the cutting dies. They are more accurate than the simple dies because of their multi-operation ability.

Progressive Dies

These dies perform multiple cutting or forming actions with each stroke, but the stroke action is applied to a different segment of the metal every time. The workpiece moves in these dies and stays at different stations. Each station performs different actions on it.

Transfer Dies

These dies are much like progressive dies but the difference is that the metal piece is transferred between stations with conveyor belts. The workpiece is cut and it is fed at each station in the transfer dies.

Multiple Dies

Multiple dies are formed when identical dies are linked together to create multiple actions per stroke. The efficiency of simple dies can also be increased by joining them together and forming one complete workstation with multiple actions being performed simultaneously.

What factors should be considered by tool and die companies when manufacturing dies?

The manufacturing of dies is not a simple process. Many different aspects are taken into consideration for the formation of dies. Some of them are:

Manufacturing Process

The type of manufacturing process to be used using the die is a major factor to be considered when producing dies. If the die is to be used on high temperatures, the die is to be durable and be able to bear the heat. If the process is going to follow the high-pressure steps, then the die should be strong enough.

The material of the part to be manufactured

The part to be manufactured can be of any material. When manufacturing the die, the chemical, physical, and mechanical properties of that material are studied. The die making process is then selected to match all the requirements.

The complexity of the part

If the part to be manufactured isn’t that complex, die making technique to be used will be simple as well. The complex parts are manufactured using complex die making processes. The die material and the die composition directly impact the structure of the part.

What tool design services are offered by tool and die companies in China?

The design of tools uses many different techniques for a compact structure. Experienced tools and die companies in China use the most advanced methods to do so. The following design services are offered by manufacturers in China:

Design Improvement

The tool design provided by the customer is studied by experienced designers at these tools and die shops. The design is then improved by these designers and a cost-effective solution is presented to the customer.

3D CAD files

The design provided by the customer is converted into a digital file by the advanced software being used at these tools and die workshops. The digital file is a computer-aided design that shows every aspect of the design from every angle.

Simulation Services

Simulation software is used to show the working of these tools by the software. It is used to provide the know-how of the complete design. From the functionality to the structure of the design, everything can be seen pre-production.

What quality measures and engineering operations are implemented by Sunrise as a leading tool and die supplier in China?

As a leading tool and die manufacturer of China, Sunrise not only produces complex tooling and die making solutions but also assures the quality of each tool and die. This is not a one-step process but takes careful insight to have the precise results. The dies and tools produced are gone through the following step to assure the quality.

Design using CAD/CAM software

The design of the tooling and dies is turned into a digital file using our CAD/CAM software services. The software helps in the designing of precise and accurate parts by maintaining the quality. Our expert designers utilize the software to copy the exact design to the digital file.

Simulation

Mold flow simulations at the design phase and the post-production phase are also carried out. This is to ensure that the tool will work according to the requirements. At the time of design, the mold flow analysis can help in the design change before it goes into the production phase. This helps save the cost required to reconstruct the tool if the defect is found post-production and optimizes tooling dies.

Tool Making

The engineers at Sunrise produce the part by using the most advanced tool-making techniques. To enhance every feature of the tools and dies, each part goes through certain procedures e.g. heat treatment, porosity control measures. The heat treatment of die cast tooling increases die life by enhancing the hardness and durability. Other measures like porosity control help remove any defects from molds.

Tooling finishing and quality testing measures

Every produced part is subjected to a specific pressure to ensure that the tool is reliable and defect-free. Tooling dimensions are measured and clamping verification is carried out.

The surfaces of all finished die casted tools and parts are tested for functionality using 100% quality tests, along with some random checking.

Hydrostatic and pneumatic are the two methods that are used to do so. The pressure of water, as well as air, is tested using these two methods. Other testing procedures are also carried out to ensure the proper working of molds and different tools.

What technologies are used by tool and die manufacturers to create the best tooling?

To create premium tooling solutions, modern tool and die manufacturers use automatic methods. CNC machining methods are the most popular choice of these companies as the chances of human error are very low in these processes.

Some of the CNC machining processes carried out by these suppliers are:

CNC milling machines

The CNC milling process is used to cut the metal piece by stability. The sideways cuts are also performed on the workpiece.

CNC lathing machines

These machines have stationary tools employed in them and the workpiece keeps on moving. As the workpiece rotates the operations are automatically performed on it without any manual labor.

Planers

This technology works exactly like the milling machine where the tools are stationary whereas the product moves around. The only difference is that planers are used to shaping flat or long surfaces.

What is the difference between die cast dies and plastic molds? Is Sunrise Metal certified as a tool and die manufacturer?

The plastic molds are formed by molding plastic into a particular shape. This means that a rigid frame is used to shape the plastic material into the required shape. The die however is the process in which the molten metal is supplied to the rigid dies. It is then left to cool down and take the shape of the mold. Once cold down, the die is removed from the part.

Sunrise is an ISO 9001 and IATF 16949 certified tool and die shop. We continuously invest in advanced measuring equipment that helps to assure the quality of the product. Our well trained and rich experienced quality team gives strict control from the incoming material to finished parts. Customer satisfaction is achieved with our strict quality control. The products are delivered on time and provide a competitive edge in the market.

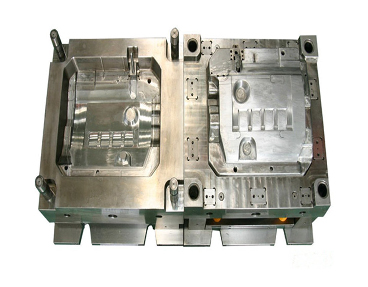

What kinds of tool and die service does Sunrise Metal offer?

Sunrise is a leading manufacturer of tools and dies in China. We offer customized solutions to our customers. The capabilities of Sunrise include:

Aluminum die cast tooling

The process is used for the tooling of aluminum die cast products. With our in-house tooling shop, we can help customers with our complete solutions from tooling design, manufacturing, modification, maintenance to tooling end management.

Zinc Die Cast Tooling

The zinc products are also subjected to tooling with our zinc die cast tooling. Sunrise provides the production as well as tooling solution for zinc products. The in-house tooling shop is utilized in creating the design, modifying the die for production, and tooling the zinc die cast product.

Rapid Prototype Tooling

The prototypes formed by Sunrise or the client’s manufactured part is tooled to meet the requirements. These prototypes are tooled using advanced equipment at the tooling shop like CNC machining and EDM processes.

Can you do the trial run with die and mold made by Sunrise Metal?

Sunrise Metals has the die casting and machining shop. Each part is manufactured with the in-house capabilities and the quality of the part is assured by testing equipment at Sunrise. We collaborate with the customer from start to finish.

The machining of the die and mold is carried out at our dedicated facility. We have the ability to test our die and mold at every step to ensure performance from the start. To ensure this performance, Sunrise Metals also provide the freedom of trial run at our facility.

The customer can ensure each functionality and check every aspect before the tooling part is produced. A trial run is offered for the dies, including mold flow analysis, which helps in maintaining quality standards. Sunrise provides this service to make the process cost-effective and to avoid any problems once the tooling is produced.

As a tool and die maker, what’s Sunrise Metal’s typical lead time?

Sunrise Metals comprises an experienced team of professionals that rapidly carries out every task. The motto of Sunrise is “speeding up your time to market”. The exact lead time, however, depends on different factors.

- The number of pieces required is one of those factors. More pieces require more time.

- The complexity of the part also directly impacts the lead time of the product.

- Your desired process used in the production of tools and dies also affects our lead time.

The fast solution can help you save 50% of your project time including the fast prototype, fast mold, fast production, fast delivery. The process can take as low as one day. The cost of the process is also made affordable for the customers.

What software does Sunrise Metal use for tool and die design?

Sunrise Metals use only advanced equipment, technology, and technique for manufacturing processes. The die design is carried out by 3D CAD design software called UG UNIGRAPHICS.

It not only allows our engineers to provide premium design capabilities but also gives a complete insight into how the part will look post-production. The software is used throughout our tool and die designs phase and also enables us to connect that design with accurate machining data.