DEDICATED RAPID PROTOTYPE TOOLING MANUFACTURER IN CHINA

- ISO9001:2015 & IATF 16949:2016 certified company

- One-Stop Prototyping Tooling Service Provider

- 10+ years experience, 4 facilities & 182 professionals

- Our Fast production assures you always on-time delivery

- Welcome High-Mix, Low volume Projects

Sunrise Metal can be your go-to prototype mold company for your upcoming project.

GET GUARANTEED QUALITY PROTOTYPE TOOLING MANUFACTURING

HOW SUNRISE METAL SUCCEED YOUR PROTOTYPE TOOLING PROJECTS

With an average of 10 years’ experienced engineering team, we provide you DFM, engineering support during the whole project life. We can achieve a thorough understanding of your prototyping tooling project and suggest improvements before production.

Sunrise Metal has a tooling facility in-house. With our one-stop prototyping tooling service, we can help you save half time to market and speed up your validation test.

The ISO 9001:2015 certification demonstrates our commitment to provide continuous quality, performance, and high-quality services for your product.

PROTOTYPING TOOLING PRODUCTION CAPABILITIES AT SUNRISE EXCEED YOUR EXPECTATION

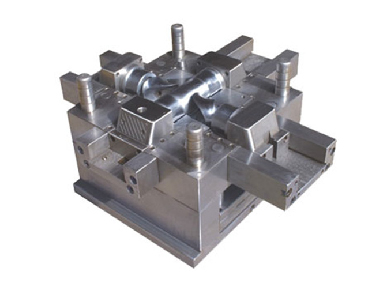

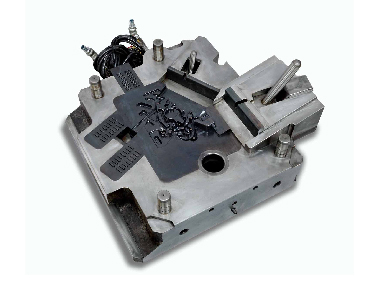

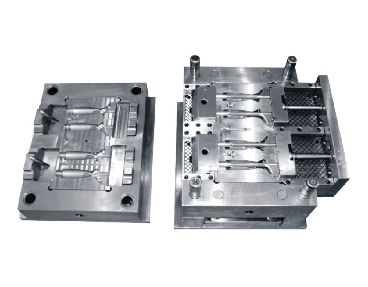

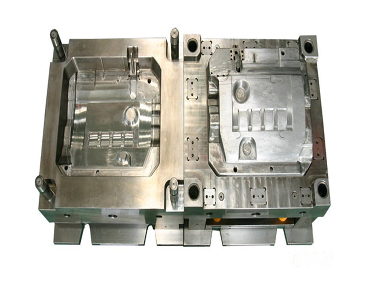

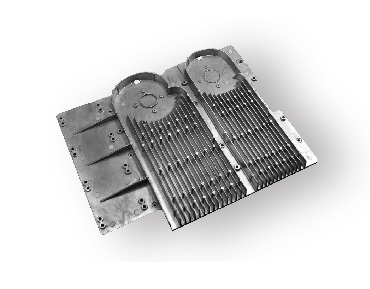

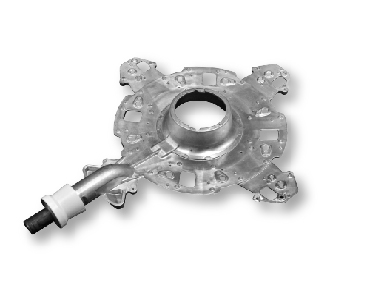

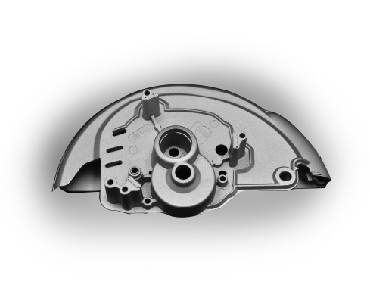

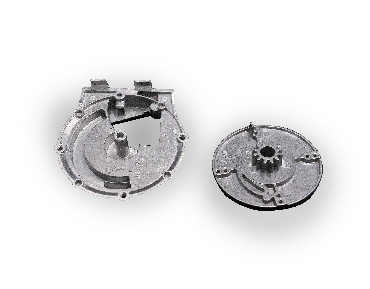

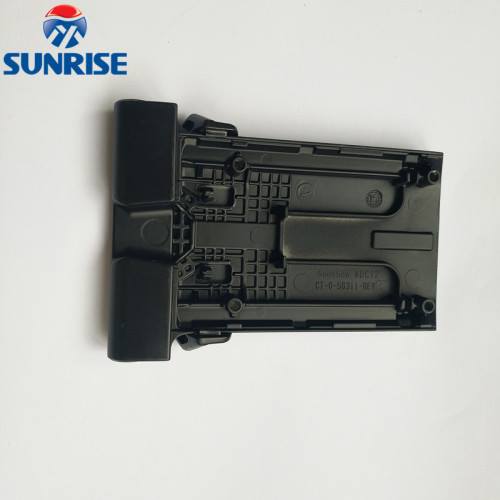

ON-GOING PRODUCTS FROM PROTOTYPE TOOLING MANUFACTURING

Sunrise Metal has been delivering comprehensive prototyping tooling manufacturing service to your global clients for many years. These projects are on-going in our production.

- Advanced Equipment

- Premium Quality

Advanced Prototype Tooling Making Equipment

| Tooling Shop (Nantong) | Brand | Type | Stroke | Unit |

| Grinder | TATUNG-OKUMA | KGS-615AHD | From 380mm to 1600mm | 4 |

| Drilling | ShenYang Machine | Z3050*16/1 | 1600mm | 1 |

| Sawer | Juli | MJ034W | NA | 1 |

| Lather | Shanghai 2nd Machine | C6250A | 1000mm | 1 |

| EDM | EDM Korea YIHAWJET Taiwan | NA | From 438mm to 1100mm | 8 |

| CNC | Local Brand | SONYU-SL850 | From 850mm to 3015mm | 5 |

| Wire Cutting | Local Brand | DK7763 | 800*630mm/1000*800mm | 2 |

| Milling Machine | Local Brand | QJM-S2 | NA | 4 |

| High-speed Cutting Machine | Local Brand | 906148 | 750mm | 1 |

| Deep Hole Drilling | Local Brand | DHD-1513 | 1513mm | 1 |

| Die Spotting Machine | Nice Dongguan | NC150-1511 | 1400mm | 1 |

| EDM/wire cutting Combined Machine | Local Brand | DK7755 | 550*630mm | 1 |

| EDM for very small hole | Local Brand | DD703 | 300*400mm | 1 |

| 3D Laser Scanner | Sikan Hangzhou | HSCAN771 | NA | 1 |

| No. | Name | Brand | Q’ty |

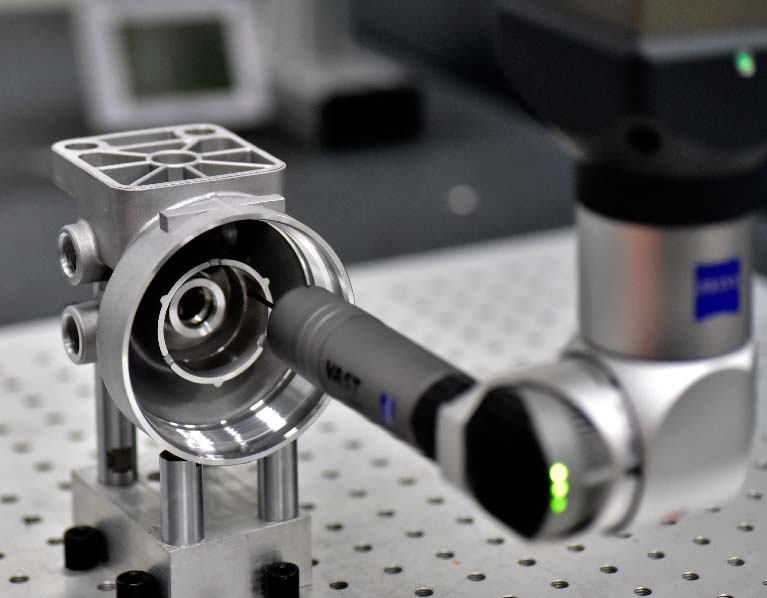

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

Get A Free Consultation

If you are looking for a Chinese prototyping tooling manufacturer, contact Sunrise Metal. When you have any hesitation or any design doubt on your aluminum die casting projects, Sunrise Metal Engineering Team can be your free consulter. Sunrise Metal gives suggestions on your aluminum die casting parts at 3 aspects:

1. Your design evaluation.

2. Feasibility analysis for mass production.

3. Project time and part’s cost-saving.

Contact us now, to see how we can help you with your prototyping tooling projects.

PROTOTYPE TOOLING MANUFACTURER:

THE ULTIMATE FAQ GUIDE

Prototype tooling manufacturing is a mandatory process for many industries now. With the advancement of technology and the growing demand for new and customized products, the designs are becoming more complex than before.

Often various industries design products that specifically serve their purpose only. Some designs are so complex and need development to work properly that prototype tooling becomes mandatory.

Prototype tooling manufacturing enables companies like automotive, aerospace, medical, or telecommunications to produce the final products’ replica. And then use it for various purposes like examining, marketing, pitching, or showcasing.

There are many aspects of prototype tooling manufacturing that every OEM, ODM, or engineer should know about. In this FAQ guide, we put together all the most necessary information that will help you choose the right manufacturer and ensure the highest product quality.

All you have to do is just scroll down and read the entire guide. And the end of it, let us know if in any way we can help you with anything.

- What materials do manufacturers use in prototype tooling?

- What is the difference in hard tooling vs. soft tooling?

- What is the difference between production and prototype tooling?

- Why is prototype tooling extremely necessary before any production?

- Types of prototype tooling methods suppliers use in China? And what does Sunrise metal use in manufacturing?

- How experienced is Sunrise Metal in prototype tooling manufacturing?

- What is the MOQ for prototype tooling manufacturing?

- How can I get a supplier who can do both prototype tooling and actual production in China?

- What are the advantages of prototype mold manufacturing?

- What is the lead time for prototype tooling from Sunrise Metal?

- What is the tolerance of the prototype tooling if I order from Sunrise Metal?

- How does sunrise metal inspect prototype tooling parts after making?

- Which industries need prototype tooling services?

- What is the quality control procedure of sunrise metal when manufacturing prototype tooling?

- Will sunrise metal help with improving my prototype design if I order from them?

- What machines are used by Sunrise Metal to manufacture the prototype molds?

- What is the basic thing you need to know before ordering prototype tooling from manufacturers in China?

- Why do manufacturers rely on CNC machining for prototype tooling?

- How to maximize the similarity between prototype parts and final products?

- How to reduce the cost and waste material in prototype tooling manufacturing?

- Can sunrise metal make a prototype mold from a part that I already own?

- Can you manufacture different surface finishing for prototype tooling parts?

- How do I know Sunrise Metal is the perfect choice for my prototype tooling project?

What materials do manufacturers use in prototype tooling?

With the constant growth and development of prototype tooling technology, there are now various materials to use. Manufacturers choose the material according to the final product, suppliers’ requirements, and machine’s needs.

Different methods require different types of materials for tooling. Subtractive methods require different materials than additive methods. For instance, Different 3-D methods require special prototyping wax.

Aluminum is also used widely for its durability and strength. For industries like automotive and aerospace, aluminum is preferred for prototyping. Because they require the prototype parts as close as possible to the final part with great strength.

On the other hand, plastic or more specifically, the thermoplastic material is also a great choice for prototype tooling. Plastic material can be shaped and customized to a great extent, making it a great choice for prototype tooling. Many plastic grades offer a great deal of strength, durability, and machinability as well.

Because of its excellent surface finishing and other features, manufacturers can use plastic for prototype tooling comfortably for various projects and industries. Some of the commonly used plastic materials are polycarbonate, nylon, acrylic, ABS, and so on.

Keep in mind that the material that is used for your project will very much depend on your requirements and design. You can suggest the material for your project too.

In Sunrise Metal, we always consult and discuss with our customers before choosing the material. When you choose Sunrise Metal for your prototype tooling project, you have the flexibility to choose the material or discuss it with us for the best alternatives.

What is the difference in hard tooling vs. soft tooling?

In prototype tooling, you’ll have to carefully decide and choose the perfect method or material for you. If you’re planning to order prototype tooling from China, you might have already encountered this aspect.

Hard tooling: When you need a prototype tooling with tight tolerances and the design is more critical, hard tooling is the way to go. This method can cost more money and take up to more days to manufacture compared to soft tooling. However, when you need a large number of parts and have an intention for functional use, hard tooling is the best option for you.

Although the price seems more expensive for this method, you’ll save money in the long run. With hard tooling, you get the best result for testing and development. It also saves time on the product approval process.

Soft Tooling: This method is very common for their fast production ability and low expense. When you don’t need tight tolerance, have low budget and time, and there is no functional use intent, you can certainly choose soft tooling for your prototype tooling project.

Soft tooling can be a fast method to execute. It has limited capabilities compared to the hard tooling method.

Before selecting the method for your project, understand your needs and requirements. Both these methods are commonly used in the prototype tooling industry. You should consult with the manufacturer first.

What is the difference between production and prototype tooling?

Many people get confused between prototype tooling and production. If you’re ordering for the first time, you might get a bit confused too. Although the process is somewhat similar between these two, there are some fundamental differences. Let’s see what those are:

Prototype tooling: This is the beginning stage of a part of manufacturing. In the prototyping stage, you order a draft version of your product according to the design. To see how the final product will look like.

Prototype tooling is a process that helps you visualize your design and enables you to finalize the design and proceed to manufacture faster. With the help of prototype tooling, you get the prototype in your hand to examine and develop the final design.

Production: After you’re satisfied with your prototype and final design, you move to this stage. Where your parts or products are actually manufactured in batches, unlike prototyping, hundreds or thousands of parts are manufactured in the production process.

Because you already examined the prototype and improved your final design according to that prototype, your final product becomes more error-proof and well-shaped.

Why is prototype tooling extremely necessary before any production?

Before we jump into why it’s important, let’s talk about what is prototype tooling first.

Prototype tooling is a tool that enables manufacturers to create a prototype or replica of your final product according to the design. A prototype is created for a variety of reasons.

Manufacturing is a costly process and often done in hundreds and thousands of units in a single batch. If there are any inaccuracies or miscalculations in the design, all the parts and products manufactured can be unusable.

With prototype molds, we can easily create replicas of the final products with very low costs and lead time. Which will be used in examining and further developing the design. Prototypes mold can help you finalize the design and the suppliers to get the exact measurement and accuracy of the design.

Without prototype tooling, there is little to no room for correction with the final products. Because when the parts are produced, manufacturing companies have very little ability to do something about it. Because it’s already done.

This is why prototype tooling plays a vital role in the production process. If you’re considering placing an order to any manufacturer, you must consider having a prototype tooling process and test the design with your prototypes. In this way, you can save money in the long run by leaving no room for errors.

Types of prototype tooling methods suppliers use in China? And what does Sunrise metal use in manufacturing?

With the rapid advancement of prototype tooling technology, there are multiple options for this now. All have their merits in their own way. The question is, which one is more suitable and beneficial for you.

Although you understand the significance of the process, it might be hard for you to decide which methods to apply. If you’re worried too, this answer will help you with that.

Let’s see some of the commonly used methods for prototype tooling.

Stereolithography (SLA) and selective laser sintering (SLS)

If you have read this FAQ guide, you already know that there are two different prototype-making methods, additive and subtractive.

SLA and SLS are subtractive methods. Because of their quick turnaround time, they are widely used in rapid prototyping. A CAD model is used in SLA for making substantial parts by hardening and curing photopolymer resin.

SLA is faster than the SLS method and great for presentations and fairs or trade shows because parts can be painted or dyed easily and make it more presentable and dressed up.

However, this method can be more expensive comparably and has limited capabilities when it comes to size. You can’t make larger parts or products using SLA.

SLS is a similar additive process to SLA. One of the major differences between these two is that it doesn’t use photopolymer resin as a material. Instead, plastic, glass, or ceramic is used to make the prototype. Which saves the cost and makes SLS cheaper than the SLA method.

Urethane mold method: This is another cost-effective method of prototype tooling that companies use here in China. The name came from its material, polyurethane plastic. This method is a better choice when you need a small number of prototypes.

The finished product is very presentable and great for marketing needs. However, this is not the most popular choice among prototype tooling and slowly, the demand for this method is fading away.

Soft tooling: This is the most preferred method in the injection molding industry. When you need faster lead time and the budget is low, soft tooling can be a great choice for prototype tooling. Soft tooling can produce a large number of units as well. This method is most favorite for its faster lead time and cost-effectiveness.

Hard tooling: Compared to soft tooling, the lead time and expense for hard tooling are much higher. However, there are some benefits you get with this method that soft tooling fails to offer.

With the hard tooling method, you can have high tolerance parts that can be used for testing and functional use. However, the lead time is higher for this method. But when you need complex design parts, being as close as the final product, hard tooling might be the best option for you.

Now that you know all the preferred options suppliers use in China, you might be wondering what methods are used by Sunrise Metal?

You’ll be glad to know Sunrise Metal owns a wide range of machines and tools designed to provide a great prototype tooling service to our customers worldwide.

Rapid prototyping: This is a complete computer automated process that can deliver the result faster than any other methods mentioned above. Rapid prototyping is a method where you can get the highest accuracy with minimal time. That makes it more convenient and a favorite among the buyers.

If you think why rapid prototyping is so widely used and why do we have a very special facility for this, see the facts below:

- With rapid prototyping. You can place a very small quantity order. The quality will still be to the greatest extent. This is suitable for you, if you don’t need to market the product, only need a small quantity to test and verify the design.

- In this method, we use the same material and process as mass production. Which lets you feel the actual product. Because of the same material used with the same production process, the parts resemble exactly like the final products.

- For the same reason, the quality of parts from rapid prototyping and mass production is identical. This is one of the reasons you will love choosing the rapid prototyping method over others. You will have a clear idea of your final product and make changes where necessary.

- Because of the faster lead time, it allows you to market the prototype faster and let you ahead of your competitors.

How experienced is Sunrise Metal in prototype tooling manufacturing?

Sunrise Metal is one of the pioneer companies in the prototyping tooling industry in China. We started our operation with prototyping back in 2003. Since then, Sunrise Metal continued to grow and expand their business prototype tooling, die casting, and other areas. Over time we became one of the leading and most trusted prototype tooling companies in China and worldwide.

Sunrise Metal has over 17 years of experience in this industry, with sixteen patents and a strong portfolio. We’ve served hundreds of global brands, including some of the leading and most renowned companies worldwide.

In the long run, we’ve successfully worked with various industries and sectors. From the medical & healthcare industries to aerospace and marine, we’ve had the opportunity to work with numerous companies over the years.

What is the MOQ for prototype tooling manufacturing?

While choosing the right prototype tooling company for your business, MOQ is an important factor to consider. Different companies have different policies when it comes to the MOQ. But in general, companies want large order quantities from the buyers.

Often OEM/ODM companies require a small number of products before production. And that could be a problem for a lot of businesses. Because large companies or manufacturers won’t take small quantity orders, and small or new companies will take the order, but often they fail to deliver the perfect products.

Sunrise Metal can help you with any quantity of rapid prototype parts. You could order as low as 1 piece as well as hundreds of thousands of pieces in each order. Sunrise Metal can fulfill all your demand most effectively and efficiently.

How can I get a supplier who can do both prototype tooling and actual production in China?

As you already know, that prototype tooling is one of the beginning stages of the production process. After you’ve made the design, you need to have a prototype ready to validate and develop the final production design.

Often OEM and ODM companies have to work with different companies for different projects like prototype tooling, manufacturing, surface finishing, assembling, etc. If you’ve gone through this, you know choosing different suppliers for various projects is a very hard job to do. Especially keeping the quality intact is very challenging when this happens.

Sunrise Metal offers a wide range of services to provide you an extraordinary one-stop solution for you. Such as rapid prototyping, tooling, die casting, machining, and assembling in house and surface treatments, together with various value-added services. And that will save you a lot of time, effort, and cost.

When looking for long-term partnerships or complex product designs, a one-stop solution manufacturer is the best way to go. Here, at Sunrise Metal, we understand this and arrange amazing facilities to deliver our clients’ desired services.

The aim was to eliminate the hassle and make it easy for businesses to find and work with a service provider or manufacturer to address all their requirements. And now, we have achieved what we aimed for.

No matter what stage of the production process you’re in right now. Feel free to leave us a message in the contact box and see how we can help your company with the best quality products.

What are the advantages of prototype mold manufacturing?

Not all the products or designs need a prototype tooling, but for the right products, this is a must thing to do. There are many undeniable benefits and advantages of it. Let’s see some of those:

Saves time and cost: Prototype tooling helps us experience the product’s exact replica before it’s manufactured. It enables us to identify any errors or inaccuracies in our design to be improved and final products are perfect.

Otherwise, if any error occurs with the final production, that could be a disaster and the products could go to wastage, which will cost a lot of money and time to reproduce the parts.

Increase user involvement: With products in hand, customers can give their opinion and feedback for the final product. That can help you redesign and improve the product that you initially planned. It also increases user engagement and your customers will feel more attached to the product. That can lead to a great increase in sales.

Helps develop a better product: When your design is complex and customized, you must order a prototype tooling service. That will help you identify the failings of the design and let you improve the final product.

Prototype tooling enables you to have the ability to recheck the design physically and more thoroughly before the actual production.

Helps with marketing and market testing: When the final product or a new model is yet to be launched, prototype mold manufacturing can be a great start for your marketing or market testing.

With a presentable prototype, you can start marketing for your product long before the production. So when the final product is ready, you already have a handful of pre-orders to serve. On the other hand, it allows you to pitch to your investors about your plan and product.

To conclude, if your product design is complex, or when you’re manufacturing a product or parts that need to be improved or need feedback, prototyping is a must. It will help you achieve the required standard of your final product that you desire.

What is the lead time for prototype tooling from Sunrise Metal?

Sunrise Metal is the leading prototype tooling manufacturer in China. We can deliver the products to our customers worldwide with a very short lead time. We understand the value of time and the urgency of our customers.

There are a couple of things that affect the lead time of your project. Which are your design, the complexity of the design, your special requirements, quantity of the order, etc. Although the lead time can vary from project to project, we ensure that our prototype tooling turnaround time will be much shorter than any other China manufacturers.

In general, Sunrise Metal takes 1-2 weeks for projects with 1-200 units. To give you an exact idea, we’ll need to look at the design and need more details about the project.

In addition to that, Sunrise Metal can deliver rapid tooling projects within 1-2 weeks, and rapid tooling parts within 1 week.

Although Sunrise Metal is located in one of China’s most versatile areas with amazing shipping arrangements, the location of your country can also make an impact.

Sunrise Metal uses rapid prototyping technology to make the prototype tooling process a lot faster and quicker than any other method. With the latest technology, most advanced machines and highly skilled workforce, we have achieved the highest speed in manufacturing prototype mold and deliver you the best results in the fastest time.

What is the tolerance of the prototype tooling if I order from Sunrise Metal?

At Sunrise Metal, we use state of the art tools and machines to provide you with the highest tolerance and accuracy of our prototype tooling. Depending on the product and design, you can determine the required tolerance of a project. Because not all parts need the same tolerance level. This can vary from project to project.

ISO 2768-1 is the industry standard for determining the prototype tooling tolerance level. The closest tolerance in this classification system is down to 50 microns, or .002 inches.

Sunrise Metal aims to provide you the best tolerance level suitable for your parts. So that the final products can be replicated and improved in design. We have the machines and tools in-house that can achieve the desired accuracy of your product.

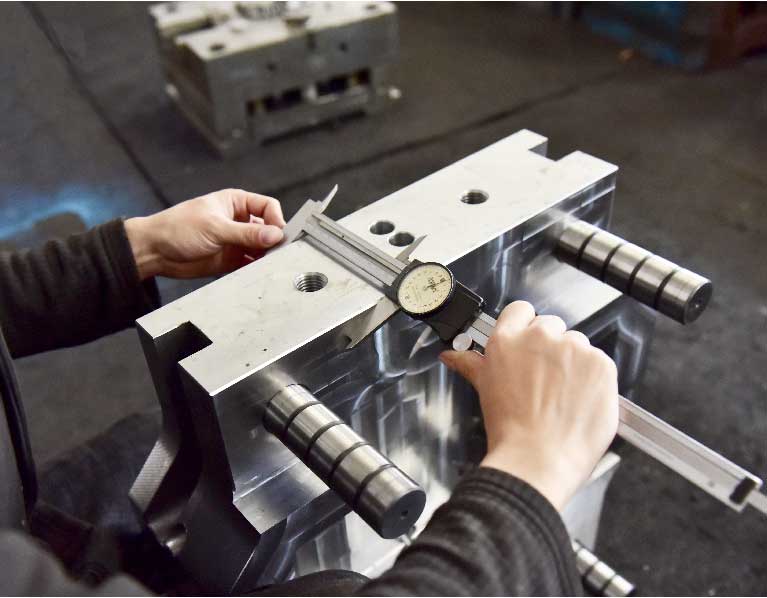

How does sunrise metal inspect prototype tooling parts after making?

After making, inspecting the prototype tooling parts is one of the most critical and essential parts of this process. Although this is not the final product faulty prototype parts can damage the development of the final product. This is why we have to ensure the highest accuracy for these parts.

At Sunrise Metal, we take our service to the next level by making exceptional prototype tooling parts. On top of that, we utilize highly advanced technologies like Spectrum Meter, X-Ray Detector, Carls Zeiss CMM, etc. to inspect the parts.

These machines allow us to inspect and determine the parts’ inaccuracy and help us deliver the perfect prototype to you. Over the years, Sunrise Metals has invested and built a system where we don’t tolerate inaccuracies and errors in our production, which helps us gain the trust of the world-renowned brands worldwide.

Which industries need prototype tooling services?

Most of the companies require prototyping tooling service before going into mass production. Especially, the most demand for prototype tooling is in the marine, medical, and automotive sectors.

The reason is obvious. They need high-quality parts or products with high accuracy and quality. The requirements of their parts are very precise and critical. Prototype tooling is extremely helpful for them.

With prototype tooling, these manufacturers can develop and improve their final products. So the production has no errors at all.

Medical industries need their products to be precise and accurate. There is no room for errors if you’re working with medical equipment and parts. For that, they need prototyping more than others to develop and produce the perfect product that matches their requirements.

Similarly, marine industries use prototype tooling for a variety of reasons. Marine industries require unique parts that need to be tested and used before mass production.

In the automotive industries, new models are launched very often. And for this new model manufacturers need to test, develop, and verify the prototype to improve the final product. And a lot of the time automotive manufacturers test the market by presenting the prototype to the market.

What is the quality control procedure of sunrise metal when manufacturing prototype tooling?

Sunrise Metal is an ISO 9001 and IATF 16949 certified prototype mold maker in China. Since the beginning of our company, we’ve always put more emphasis on quality. At Sunrise Metal, compromising quality is not an option for us.

From the design and raw material to the final product, inspection, and shipping, we ensure the highest quality to get ultimate customer satisfaction.

Over the years, Sunrise Metal has achieved the highest peak of quality control with advanced technology and a highly skilled quality control workforce. Our QC team works very hard to ensure you get the exact products that you desire. We don’t believe in shortcuts when it comes to the quality of our products.

We get orders ranging from one-two pieces to hundreds of thousands of pieces from all around the globe. No matter the size of the order and the design complexity, Sunrise Metal is committed to providing the highest quality for you.

With the integration of technology, our quality control strategy, and our dedicated QC team, there is no scope of errors. We have over ten years of experience serving quality products to our customers and gaining their trust and dependency.

If you’re concerned about your valuable parts’ quality and want to see it by yourself, we invite you to our factory. Have a factory visit to our facilities and see by yourself how our QC team works hard to provide you the parts that will make your business grow.

Will sunrise metal help with improving my prototype design if I order from them?

Sunrise Metal is dedicated to providing the best customer service to our customers. We offer genuine consultancy and help in every stage of the production. We believe in partnerships. We aim to make the product perfect and eliminate any errors that may occur. And in doing so, we aspire to help our customers with their designs as well.

If you need any help with the design you have, our skilled designers will happily assist you. On top of that, before we jump into the tooling process, we will examine the design thoroughly and make sure it has no inaccuracies or errors.

Helping our customers is not only an option for us, it’s a duty, we believe. From the beginning of the production process, such as the design stage to the shipping stage, we’re always ready and happy to help our customers to have a better experience working with us.

What machines are used by Sunrise Metal to manufacture the prototype molds?

Sunrise Metal has the state of the art machines and technologies to help you with the best prototype tooling service that you require. We use the most advanced machines and tools available to produce the best parts for our customers.

Here are the tools and machines we use for this:

| NO. | Name | Quantity | Stroke |

| 1 | Mazak 7-axis turning & milling Machine | 1 | Ф658*1011MM |

| 2 | Mazak /Hass 5-axis CNC Machine | 2 | Ф800/Ф600 |

| 3 | 3-axis CNC Machine Center | 1 | 2000*1500MM |

| 4 | 4-axis CNC Machine Center | 12 | Ф250*800MM |

| 5 | 3-axis CNC Machine Center | 20 | 1000*600*600MM |

| 6 | CNC Lathes | 2 | Ф320*800/Ф610*1000MM |

| 7 | Sodick Wire Cutting Machine | 3 | 400*400*200MM |

| 8 | EDM Machine | 2 | 500*400*400MM |

| 9 | Surface grinder | 1 | 600*300*200MM |

What is the basic thing you need to know before ordering prototype tooling from manufacturers in China?

If you’re ordering for the first time, you must know certain things before choosing a manufacturer or placing an order for prototype tooling.

Choosing the right manufacturer: This can make or break your project as it might be one of the most important parts of your production process. When you decide to work with an experienced manufacturer with a proven track record and excellent customer service, half of your work is done. Because most of the time, they will help with every stage of the production process.

Getting the design right: Design is another critical element of the process that needs special attention. You’ll need to have a design that is compatible with CAD and the machines. Make sure that the design works great and free of any errors.

Get the measurements right: The measurements of your products also play a vital role in manufacturing. Ensure that all the measurements are accurate.

Choosing the right process: As you already know, various options are available for the prototyping tooling. You must choose the right one for you. Because for pricing or any other issues, you fail to choose the right process for your project, you won’t get the best results.

Detailed instructions, including tolerances: Remember that you’re the one that has the best understanding of your products. Provide detailed instructions to your manufacturer, including the tolerance level that you want your products to have.

Consider the application: Your prototype tooling can very much rely on the application you have in mind. This can also change the raw material of your prototype tooling manufacture process.

These are some basic and most important things to consider. As I’ve said before, choosing the right manufacturer can help or hurt you in all other factors. So make a better choice by selecting a great one. Check and verify the quality, certifications and track record of the manufacturer before placing the actual order.

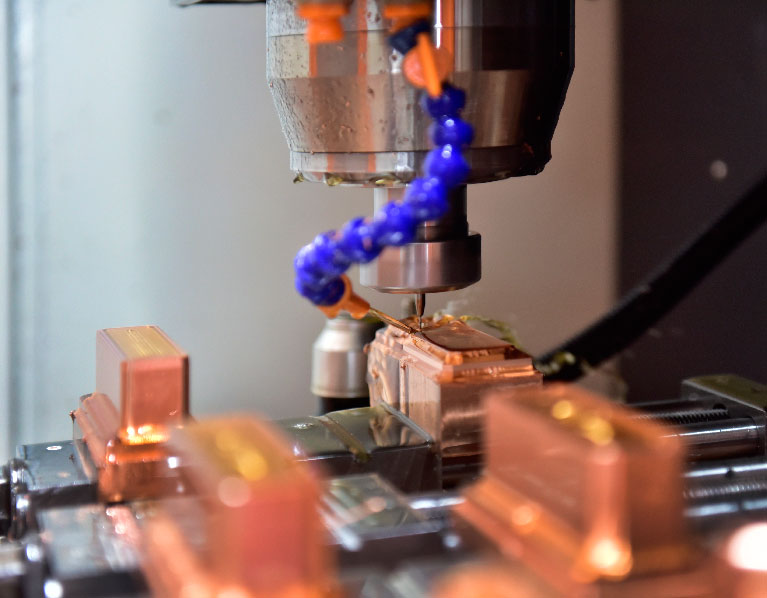

Why do manufacturers rely on CNC machining for prototype tooling?

CNC machining is one of the most preferred ways of manufacturing prototype molds. This is a subtractive process that delivers the best result in the prototype tooling industry.

CNC machining for prototype tooling is the most convenient and reliable method among all. In this method, the machine uses a computer-generated 3D design to produce the parts, which makes the measurement very accurate and closer to the final design.

If any error is identified with the design or prototypes with CNC machining, it’s very easy to make changes and make the next prototype error-free. Because the same design can be used for the final product and the similarity between the prototype and the final product is very close.

This method is faster than any other alternatives while providing a great result. Different material options can be used too.

For these reasons, prototype tooling suppliers in China, including Sunrise Metal, rely on CNC machining for most projects. It enables us to provide our customers with great quality products in less time.

How to maximize the similarity between prototype parts and final products?

The goal of prototyping tooling is to make a close replica of the final products. There are different prototyping methods. But when you need the closest match with the final parts, we suggest you choose rapid prototyping.

In this method, we use a similar process and material as the final production. So you can get the product exactly like the finished parts.

Rapid tooling is a completely computer-operated method. It enables us to create prototype parts in a very short time and the quality is very similar to the mass production parts.

How to reduce the cost and waste material in prototype tooling manufacturing?

Cost and wastage are important factors to consider while choosing the right process for your prototype tooling manufacturing process. A very small amount of changes in cost for a large volume of orders can have a significant impact on your budget. Certain elements need to be considered to get the best quality products at a reasonable cost and minimum wastage.

First, you’ll need to communicate with your manufacturer or supplier thoroughly. Ensure both of you are on the same page and understand each other. Consulting with your manufacturer about the cost and waste material is the best way to minimize those. Because they know all the processes and ways for this. All you have to do is make them understand your requirements. And the manufacturer should be able to identify the best option for you.

Second, you need to review your design thoroughly multiple times. Sometimes fixing your design can save you a ton of money and time upfront. Make sure your design is perfect and ready to be manufactured. You can consult with your manufacturing company’s in house designers too for better understanding.

Third, before going into prototype tooling, you can perform simulating testing as well. It will help you visualize the design and identify any errors.

Can sunrise metal make a prototype mold from a part that I already own?

Of course! We often get clients who want us to replicate a product they already own or collected from somewhere. We can successfully make a prototype mold from your part and provide you prototypes that closely resemble your pre-owned part.

If you’re an OEM/ODM company and have a part in hand that needs to be tested and improved, we can help you with that. All you have to do is send us the part and let us know your exact requirements in detail.

After that, we’ll make the design exactly like your parts, and we’ll make prototype molds that will enable you to test and develop the design of your final parts.

Can you manufacture different surface finishing for prototype tooling parts?

Sunrise Metal is a one-stop solution for your desired service. We don’t leave the work undone for any of our customers. When you work with Sunrise Metal, we provide you the required surface finishing service for your prototype tooling.

Sunrise Metal will help you in technical aspects of surface finishing and provide advisory support for you. We have a wide variety of options for our customers to choose from. We’ll also help you choose the right surface finishing that goes with your parts and your budget.

Here are some of the options you can choose from:

- Anodized finishing

- Chromating or alodine finishing

- Powder coating finishing

- Wet Painting finishing

- Plating finishing

- E-coating finishing

How do I know Sunrise Metal is the perfect choice for my prototype tooling project?

If you’ve never worked with Sunrise Metal and unaware of our service, we’re very glad that you’re reading this answer to know about us.

Sunrise Metal is a leading manufacturer in China in prototype tooling, aluminum die casting, machining. We can guarantee you the highest quality of products even before the production.

Sunrise Metal has successfully served more than 200 world-renowned companies with various small, medium, and large projects. Our primary focus is on quality. This is the reason why we get the appreciation of our customers after every project.

One of the reasons you’ll love us is that we accept orders based on the MOQ. We welcome low MOQs, even if it is only one, and high mix as well.

Some other companies do it too, but there is a big difference between them and us. And that is, we don’t compromise quality. Because no one wants poor quality for their business, we work hard to provide the best quality products at an affordable price, so our customers can comfortably grow their business.

Our quality control team checks the quality and inspects all aspects of the products while in production and after production. That eliminates any chance of errors and ensures you’re getting the best results.

If you’re like us and believe in actions, other than words, we welcome you to have a visit to our factories. So that you know who you’re working with and what capabilities do we have.

Conclusion:

To conclude, there is no denying that prototype tooling is a vital element of a production process. And selecting the right prototype tooling manufacturer and getting the job done is often harder than it seems.

Sunrise Metal makes the process easy for you and your company. We ensure the highest quality at an affordable price and deliver you the best result.

If you’re looking for the perfect prototype tooling manufacturer, I strongly suggest you get in touch with us now. And let’s see how we can help each other grow our business together.